Metallic nickel/graphene composite wave-absorbing material and preparation method thereof

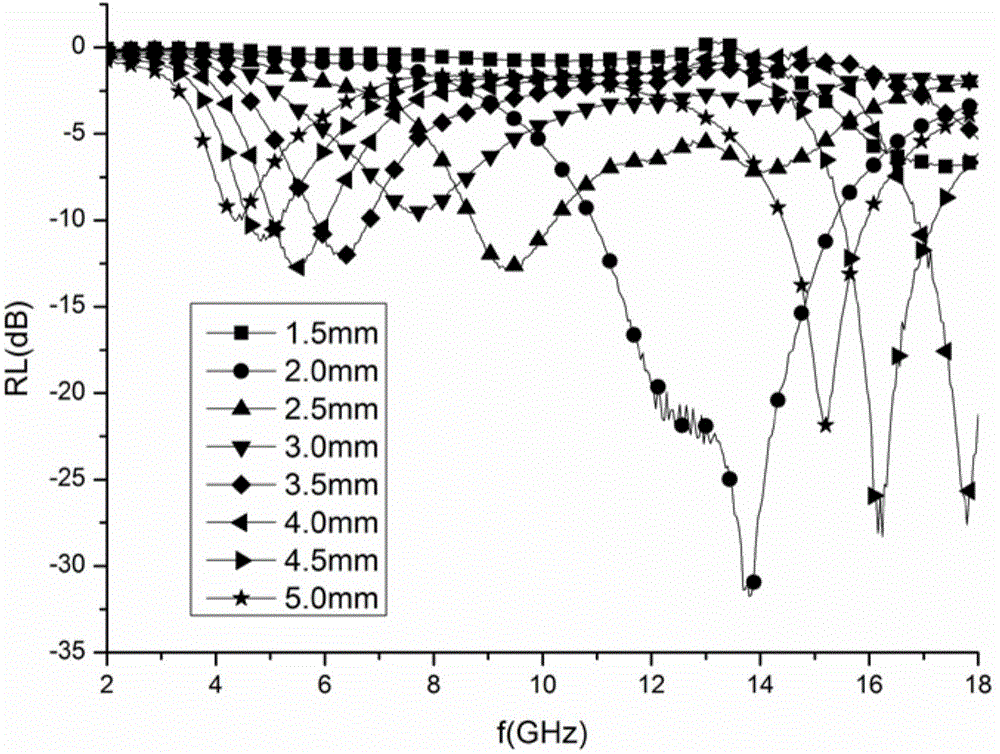

A graphene composite and wave absorbing material technology, applied in the field of wave absorbing materials, can solve the problems of complicated preparation process, long preparation time, narrow absorption frequency band, etc., and achieve the effect of obvious absorption intensity, simple preparation process and realization of preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

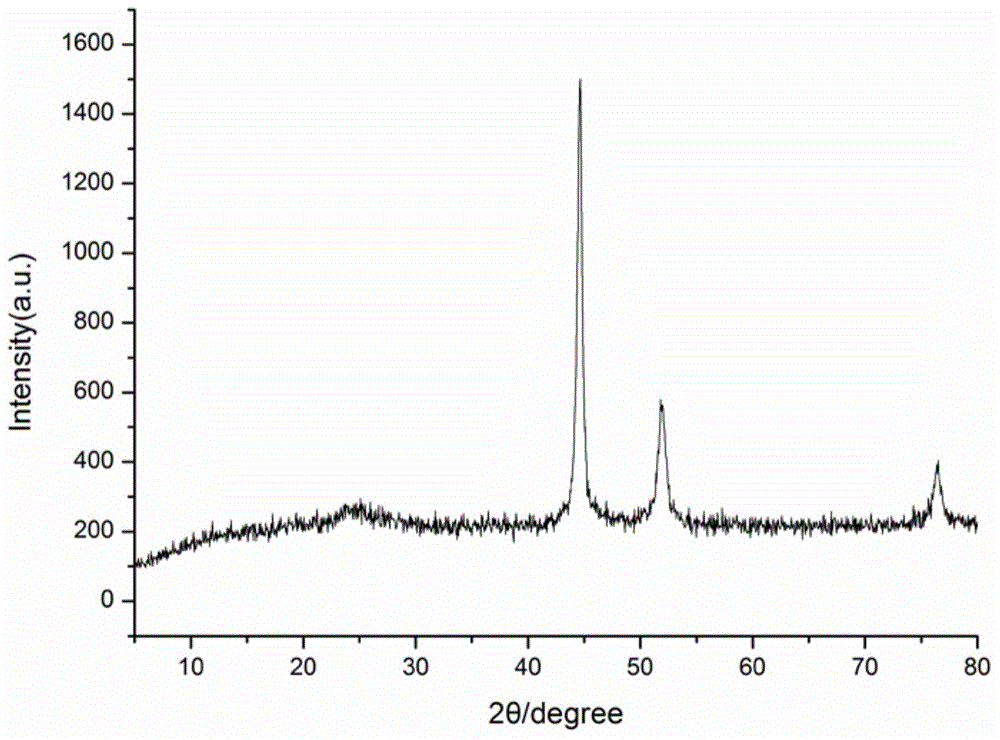

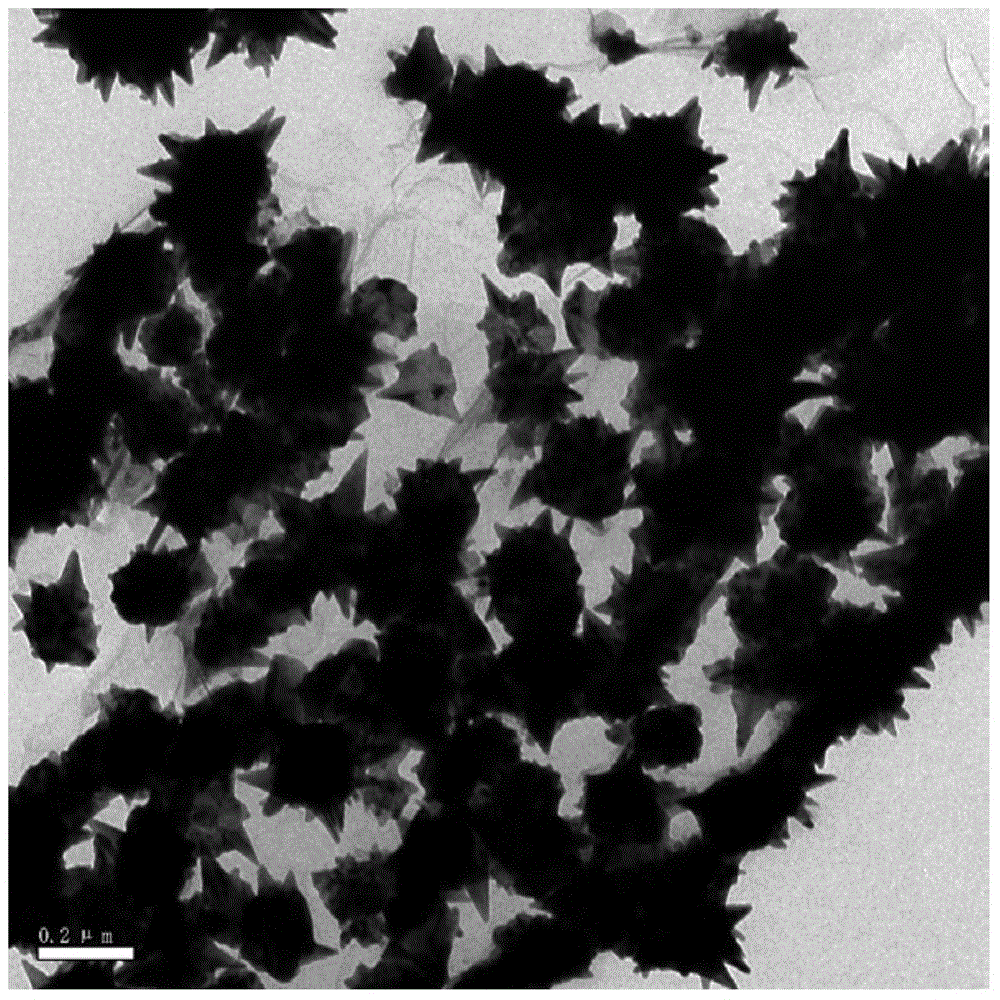

[0022] Graphite oxide by mass: nickel chloride hexahydrate=1:2.38, graphite oxide: ethylene glycol=1:1332 Weigh 0.05g graphite oxide and 0.1188g nickel chloride hexahydrate and disperse in 60mL ethylene glycol by ultrasonic 1h A mixed dispersion is formed. Sodium hydroxide by mass ratio: hydrazine hydrate=1:20 takes by weighing 0.5g sodium hydroxide and is dissolved in 10mL hydrazine hydrate (80wt%) to form mixed solution, mixed solution by mass ratio: dispersion liquid=1:6.34 this mixed solution is added into the above dispersion liquid, stirred magnetically for 10 minutes, poured it into a polytetrafluoroethylene-lined autoclave, placed it in a 200°C oven for 45 minutes, cooled it to room temperature and washed it several times with ethanol and deionized water. Dry in a vacuum drying oven to obtain the thorn ball-shaped metal nickel / graphene composite wave-absorbing material. From figure 1 It can be seen that the thorny ball-shaped metallic nickel of the present invention ...

Embodiment 2

[0024] Graphite oxide by mass: nickel chloride hexahydrate=1:4.79, graphite oxide: ethylene glycol=1:1332 Weigh 0.05g graphite oxide and 0.2377g nickel chloride hexahydrate and disperse in 60mL ethylene glycol by ultrasonic 1h A mixed dispersion is formed. Sodium hydroxide by mass ratio: hydrazine hydrate=1:24 takes by weighing 0.5g sodium hydroxide and is dissolved in 12mL hydrazine hydrate (80wt%) to form mixed solution, mixed solution by mass ratio: dispersion liquid=1:5.3 this mixed solution Add it to the above dispersion, stir it magnetically for 10 minutes, pour it into a polytetrafluoroethylene-lined autoclave, place it in an oven at 220°C for 30 minutes, cool it to room temperature and wash it with ethanol and deionized water for several times, and then the product obtained in Dry in a vacuum drying oven to obtain the thorn ball-shaped metal nickel / graphene composite wave-absorbing material.

Embodiment 3

[0026] Graphite oxide by mass: nickel chloride hexahydrate=1:1.19, graphite oxide: ethylene glycol=1:1332 Weigh 0.05g graphite oxide and 0.0594g nickel chloride hexahydrate and disperse in 60mL ethylene glycol by ultrasonic 1h A mixed dispersion is formed. Sodium hydroxide by mass: hydrazine hydrate=1:16 takes by weighing 0.5g sodium hydroxide and is dissolved in 8mL hydrazine hydrate (80wt%) to form mixed solution, by mass ratio mixed solution: dispersion liquid=1:7.8 this mixed solution Add it to the above dispersion, stir it magnetically for 10 minutes, pour it into a polytetrafluoroethylene-lined autoclave, place it in a 180°C oven for 1.5 hours, cool it to room temperature, wash it with ethanol and deionized water several times, and then the product Dry in a vacuum drying oven to obtain the thorn ball-shaped metallic nickel / graphene composite wave-absorbing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com