Mutant of cellulose exocellobiohydrolase CBH I and viscosity reducer of syrup in corn fuel ethanol fermentation production

An exoglucanase and cellulose technology, applied in fermentation, biofuel, enzymes, etc., can solve the problems of increasing energy consumption of feed drying steam, dark color of DDGS, destruction of nutrients, etc., and achieve excellent enzyme stability and catalytic activity, reducing steam consumption, and improving the first-grade product rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation and Properties of Cellulose Exoglucanase CBH I Mutant

[0029] 1. Sequence of the mutant

[0030] The amino acid sequence of Trichoderma reesei cellulose exoglucanase CBH I is shown in SEQ ID NO:1, and the gene cDNA sequence is shown in SEQ ID NO:2.

[0031] After analysis by the molecular simulation software PROPKA software, the tyrosine (Y) at position 68 of the amino acid sequence of Trichoderma reesei cellulosic exoglucanase CBH I was replaced with glycine (G) to obtain mutant Y68G, and the corresponding replacement Codon (substitute GGT for TAC at positions 202-204 in SEQ ID NO:2). For Escherichia coli, the website http: / / www.jcat.de was used for codon optimization, and finally the coding gene of mutant Y68G (SEQ ID NO: 3) was obtained. In addition, the tyrosine (Y) at position 68 of the amino acid sequence of Trichoderma reesei cellulose exoglucanase CBH I was replaced with alanine (A) to obtain mutant Y68A, and the mutation was obtained by...

Embodiment 2

[0044] The preparation of embodiment 2 viscosity reducer

[0045] Viscosity reducers of the following compositions were prepared respectively. The parts in this embodiment are parts by mass. The original cellulosic exoglucanase CBH I in this example, two kinds of mutants Y68G and Y68A, respectively obtain the crude enzyme liquid according to the method in Example 1, then according to Document 1 (Pan Feng et al., Usami Aspergillus Y- 26 The purification and enzymatic properties of cellulase, the method in Nanjing University of Science and Technology, 2001) method to purify each cellulosic exoglucanase and freeze-drying, the specific activity of cellulosic exoglucanase CBH I is 21500U / g, the specific activity of mutant Y68G is 39600U / g, and the specific activity of Y68A is 38400U / g. Information on the rest of the enzymes used as table 2 shown.

[0046] Table 2 Information on enzymes used in complex viscosity reducers

[0047] Enzyme name factory product nu...

Embodiment 3

[0054] Application of embodiment 3 viscosity reducer

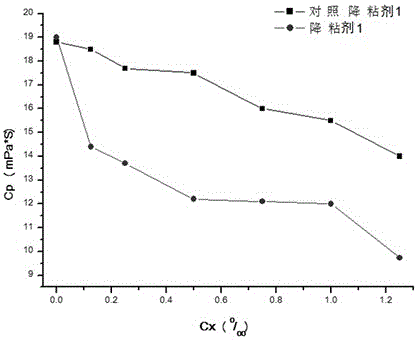

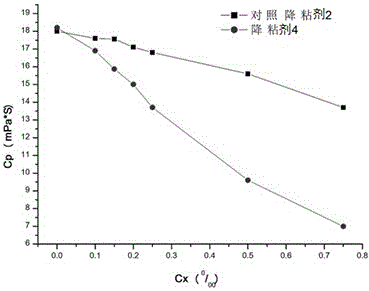

[0055] The technological process of corn fuel ethanol fermentation is: corn flour—pulp mixing—adding enzyme preparation and yeast—raw meal fermentation—distillation—dehydration—fuel ethanol. The addition amount of each substance in the fermentation is 2kg of corn flour, 0.1-0.5% of yeast, 20-80U / g corn flour of alpha-amylase, and 100-200U / g corn flour of glucoamylase. Fermentation conditions: material-to-water ratio 1:2-1:5, constant temperature 28-35°C, stirring speed 100-200r / min, fermentation without cooking for 3-6 days. After the fermentation is finished, the fuel ethanol is distilled out, and the distillation waste mash is filtered to obtain a clear liquid. Concentrate the supernatant to a syrup with a concentration (mass percentage of dry matter, the same below) of 29%. Viscosity reduction agent 1 and comparison viscosity reduction agent 1, viscosity reduction agent 4 and comparison viscosity reduction agent 2 in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific vitality | aaaaa | aaaaa |

| Specific vitality | aaaaa | aaaaa |

| Specific vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com