Polytetrafluoroethylene modified chromium-free Dacromet paint and preparation method of composite coating thereof

A polytetrafluoroethylene, modified technology, applied in coatings, anti-corrosion coatings, devices for coating liquid on the surface, etc., can solve the problems of poor corrosion resistance of coatings, environmental and human hazards, and inability to effectively protect substrates. Material and other issues, to achieve excellent corrosion resistance and thermal shock resistance, stable coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

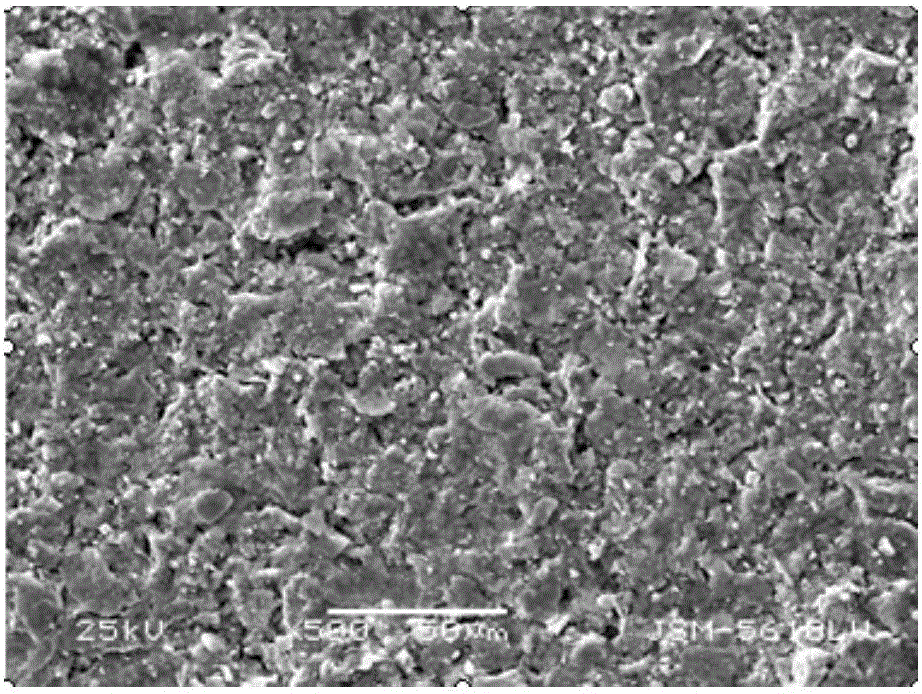

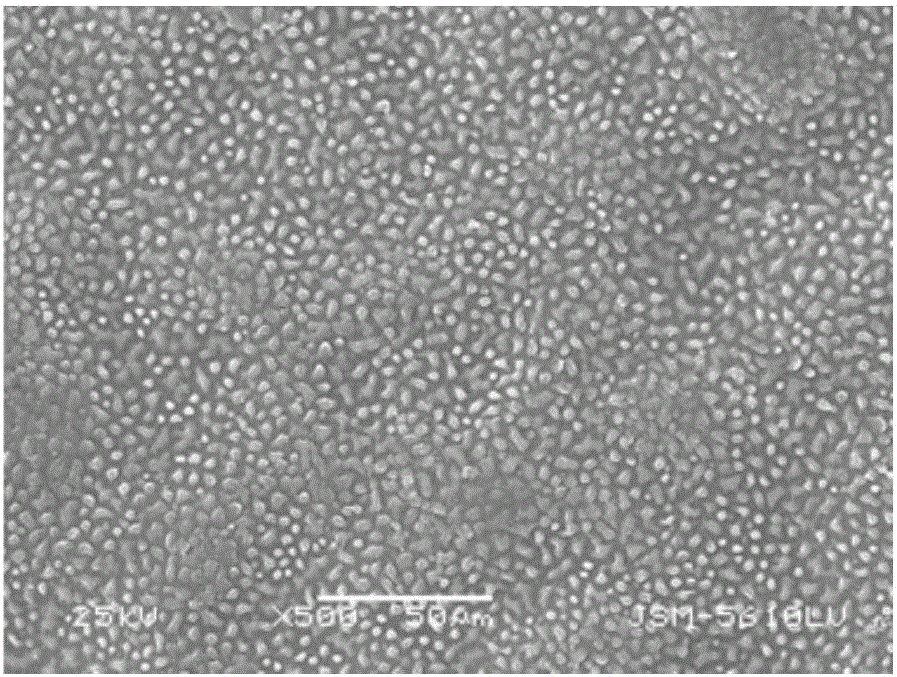

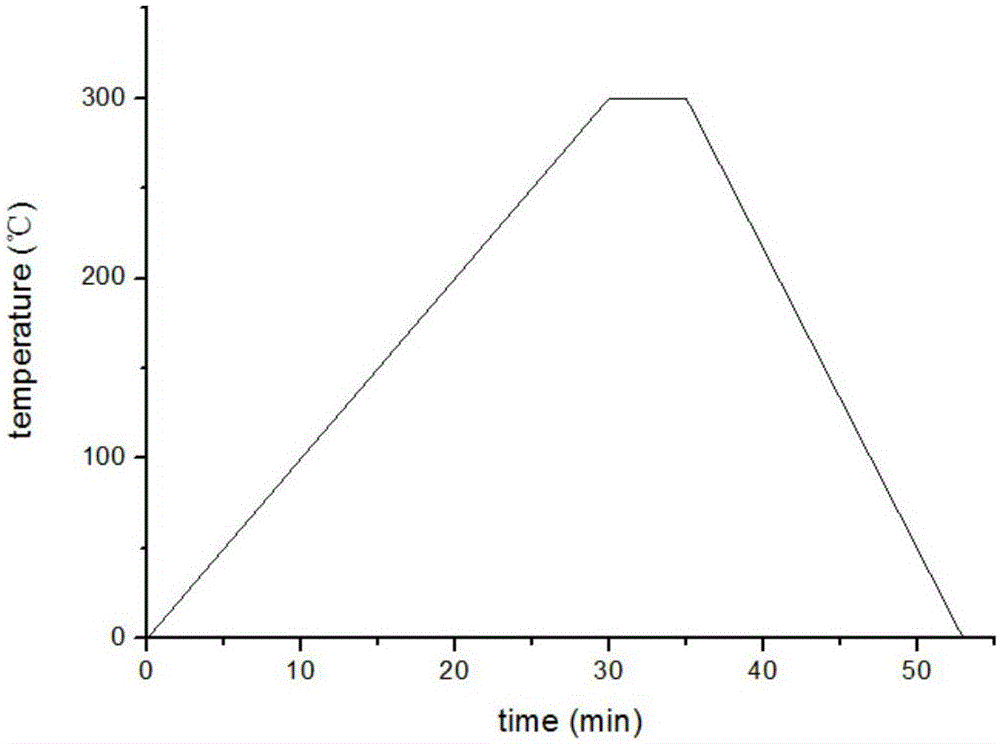

Embodiment 1

[0048] Ingredients: Take 8.0 kg of metal paste [which contains 33% flake zinc powder, 33% flake aluminum powder, 34% magnesium powder, a total of 4.0 kg, and an equivalent amount of polyethylene glycol 400 (ie 4.0 kg)] . Take 1.0 kg of chromium-free passivation agent [which contains 40% ammonium molybdate, 15% citric acid, 15% boric acid, 10% silane coupling agent (KH-560), 20% rare earth material (terbium oxide)], take water Add 6.6 kg into the weighed chromium-free passivating agent and stir to obtain the chromium-free passivating solution. Pour the metal slurry and chromium-free passivation solution into a polyethylene bucket and mix evenly, then stir at a constant speed, add 100 grams of HEC thickener (hydroxymethyl cellulose), 1.4 kilograms of polytetrafluoroethylene suspension [such as : JF-4DC polytetrafluoroethylene suspension produced by Zhejiang Juhua Group] and 80 grams of dispersant (sodium dodecylbenzene sulfonate) and 50 grams of ethylene glycol (related additiv...

Embodiment 2

[0058] Ingredients: Take 7.2 kg of metal paste [which contains 20% flake zinc powder, 40% flake aluminum powder, 40% magnesium powder, a total of 3.6 kg, and an equivalent amount of polyethylene glycol 400 (ie 3.6 kg)] . Take 1.3 kg of chromium-free passivation agent [which contains 38% ammonium molybdate, 15% citric acid, 16% boric acid, 6% silane coupling agent (KH-560), 25% rare earth material (cerium oxide)], take water 7.0 kg was poured into the weighed chromium-free passivation agent and stirred to obtain the chromium-free passivation solution. Pour the metal paste and chromium-free passivation solution into polyethylene barrels and mix evenly, then stir at a constant speed, add 90 grams of HEC thickener (hydroxymethyl cellulose), 2.0 kilograms of polytetrafluoroethylene suspension and 75 gram dispersant (sodium dodecylbenzene sulfonate) and 50 gram ethylene glycol (related auxiliary). Stir rapidly at room temperature for 7 hours. During this continuous stirring proces...

Embodiment 3

[0063] Ingredients: take 8.6 kg of metal paste [among them, the weight of flake zinc powder, flake aluminum powder, and magnesium powder each accounts for 1 / 3, a total of 4.3 kg; and the same amount of polyethylene glycol 400 (ie 4.3 kg) 】. Get 1.4 kg of chromium-free passivating agent [which contains 35% ammonium molybdate, 15% citric acid, 15% boric acid, 12% silane coupling agent (KH-560), 23% rare earth material (lanthanum nitrate)], take Pour 6.8 kg of water into the weighed chromium-free passivation agent and stir to obtain the chromium-free passivation solution. Pour the metal slurry and chromium-free passivation solution into polyethylene barrels and mix them evenly, then stir at a constant speed, add 95 grams of HEC thickener (hydroxymethyl cellulose), 1.5 kilograms of polytetrafluoroethylene suspension and 80 gram of dispersant (sodium dodecylbenzenesulfonate) and 55 grams of ethylene glycol (associated additives). Stir rapidly at room temperature for 7.5 hours. Du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com