Strain and method for producing glucosamine through microorganism fermentation

A glucosamine and microbial fermentation technology applied in the biological field to achieve low cost, short production cycle, and stable production and supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

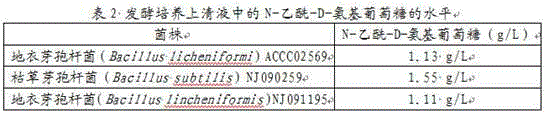

[0043] According to another aspect of the present invention, the D-glucosamine method of producing N-acetyl-D-glucosamine and D-glucosamine by fermentation of the above bacterial strains is used as the starting strain to produce N-acetyl-D-glucosamine through seed culture and optimized medium fermentation. Acetyl-D-glucosamine and D-glucosamine, including the following steps:

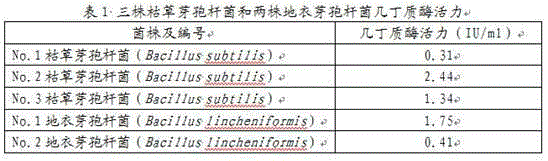

[0044] (1) Strain screening, identification and cultivation

[0045] Collect 50 soil samples, dilute them 10-3 times and spread them on the primary screening plate. Use the primary screening medium: colloidal chitin 2.5g / L, dipotassium hydrogen phosphate 0.7g / L, potassium dihydrogen phosphate 0.3g / L L, Magnesium Sulfate 0.5g / L, Ferrous Sulfate 0.01g / L, Agar 20g / L, pH 7.0, culture temperature 37°C, culture time 72h, cultured, obtained a single colony, separated the colony, and obtained 11 transparent colonies The strains with large and bright circles and good growth conditions were identified according ...

Embodiment 2

[0078] (1) UV radiation-induced mutation

[0079] Take 10ml1×10 7 individual / ml Bacillus subtilis ( Bacillus subtilis ) NJ090259 suspension was placed in a 9cm-diameter petri dish, and the ultraviolet lamp was preheated for 20 minutes. The petri dish was placed on a magnetic stirrer and the vertical distance of the petri dish was about 30cm from a 10W ultraviolet lamp; turn on the magnetic stirrer and irradiate 150, 200, 250, 300s; after the mutagenesis of the bacteria solution, let it stand in the refrigerator for 1-2 hours in the dark, take the mutagenized strains and the starting strains and inoculate them on the chitin medium plate respectively, and select the chitin medium plates with fast growth speed. The ratio of hydrolysis circle to colony diameter is greater than 10% of the starting bacteria and the largest mutant is tested for enzyme activity;

[0080] Chitin medium: colloidal chitin 30g / L, ammonium sulfate 2.0g / L, magnesium sulfate 0.5g / L, potassium dihydrogen p...

Embodiment 3

[0089] (1) Bacillus subtilis ( Bacillus subtilis ) NJ090259 UV-induced mutant fed-feed fermentation test

[0090] UV-induced Bacillus subtilis ( Bacillus subtilis ) After the largest mutant of NJ090259 was placed on the plate medium for activation, it was inserted into the seed medium and cultured in a constant temperature shaking table at 30°C for 18 hours, which was used as the seed liquid; when inoculated, it was inserted into 50ml of fermentation culture at a ratio of 1:10 In the base 250mL baffled Erlenmeyer flask, add 2.5ml of feed medium at 24h, 36h, 48h, and 60h respectively;

[0091] Fermentation medium: colloidal chitin 10g / L, glucose 10g / L, yeast extract 3.0g / L, MgSO 4 ·7H 2 O0.6g / L, FeSO 4 ·7H 2 O0.01g / L, KH 2 PO 4 0.4g / L, K 2 HPO 4 0.6g / L, ZnSO 4 0.001g / L;

[0092] Feed medium: colloidal chitin 100g / L, glucose 100g / L, pH 6.0.

[0093] Culture conditions: pH 6.5, culture temperature 35°C, constant temperature shaker culture, culture time 72h.

[0094...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com