Doped lithium ion battery anode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in the field of materials, can solve the problems of reducing the coulombic efficiency of materials and limited conductivity of materials, and achieve the effects of universal applicability, uniform size, and wide controllable selection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Ultrasonic dispersion

[0031] Take 1.5426g of Nb 2 o 5 and 0.4403 g of TiO 2 and 0.01479g of Al 2 o 3 Separately disperse in n-hexane submerged in materials, ultrasonically and stir evenly, then mix, continue ultrasonically and stir for 2 hours to obtain a uniformly dispersed solution.

[0032] (2) Ball milling

[0033] The obtained solution was poured into a ball mill tank, and the spherical mass ratio was adjusted to 25:1, and ball milled in a planetary high-energy ball mill at a speed of 300 rpm for 10 h, and the remaining powder was collected after the slurry was blast-dried.

[0034] (3) High temperature heat treatment

[0035] The collected samples were treated at 1000°C for 30 hours in an air atmosphere to prepare the lithium-ion battery anode material Ti 0.95 al 0.05 Nb 2 o 7 .

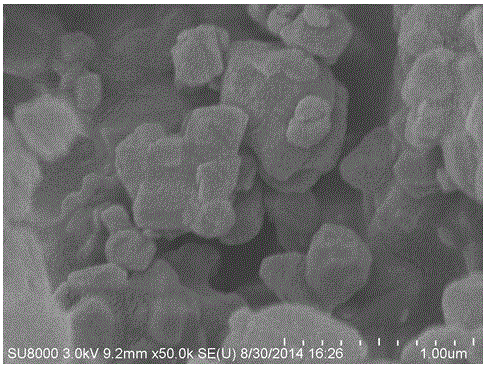

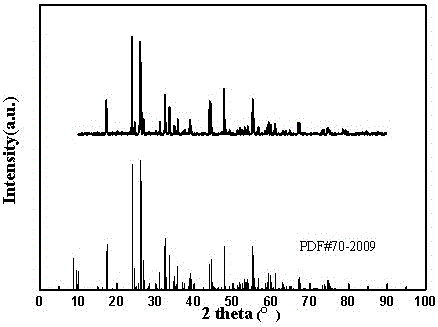

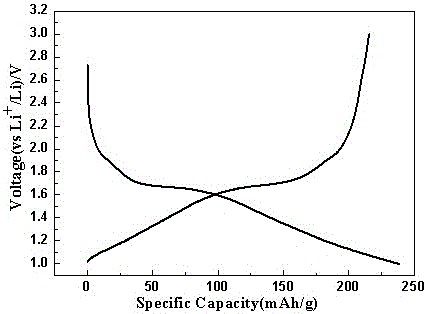

[0036] The morphology of the material prepared in this example with 5% Al instead of Ti is as follows figure 1 As shown, it can be seen that the morphology of the mater...

Embodiment 2

[0039] (1) Dispersion solution

[0040] Weigh 3.1289g of NbCl 5 and 1.9689g of tetrabutyl titanate were respectively dispersed in 200mL of absolute ethanol, and mixed with ultrasonication and stirring evenly, and continued ultrasonication and stirring for 2 hours to obtain a uniformly dispersed solution.

[0041](2) Adjust the pH and stir to form a gel

[0042] Glacial acetic acid was added to the obtained solution to adjust the pH to 2-5, and then heated and stirred in an oil bath with the temperature controlled at 50°C until a sol was obtained.

[0043] (3) Drying to prepare xerogel

[0044] Transfer the sol to a blast drying oven, adjust the temperature to 50-100°C until the sol turns into a gel, then adjust the temperature to 80-160°C, and dry to obtain a xerogel.

[0045] (4) High temperature heat treatment

[0046] Grind the xerogel obtained in Step 3 finely, then put the material into a quartz crucible and transfer it to a tube furnace, heat it up to 900°C in an air...

Embodiment 3

[0049] (1) Dispersion solution

[0050] Weigh 0.9750g of tetrabutyl titanate, 0.8142g of isopropyl titanate and 1.5492g of Nb 2 (C 2 o 4 ) 5 and 1.8324g of Nb(C 2 h 5 O) 5 , 0.0110g of zinc oxalate and 0.0088g of copper oxalate were respectively dispersed in 200mL of absolute ethanol, ultrasonically and stirred evenly, and then mixed, and continued ultrasonically and stirred for 2 hours to obtain a uniformly dispersed solution.

[0051] (2) Adjust the pH and stir to form a gel

[0052] Glacial acetic acid was added to the obtained solution to adjust the pH to 2-5, and then heated and stirred in an oil bath with the temperature controlled at 50°C until a sol was obtained.

[0053] (3) Drying to prepare xerogel

[0054] The sol was transferred to a blast drying oven, and the temperature was adjusted to 80° C. until the sol turned into a gel, and then the temperature was adjusted to 160° C., and dried to obtain a xerogel.

[0055] (4) High temperature heat treatment

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com