Lithium-ion battery anode material molybdenum disulfide/carbon and preparation method thereof

A lithium-ion battery and negative electrode material technology, applied in the field of lithium-ion battery negative electrode material molybdenum disulfide/carbon and its preparation, can solve the problems of low cycle stability, capacity loss, poor cycle stability, etc., and achieve strong operability, High specific capacity, simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

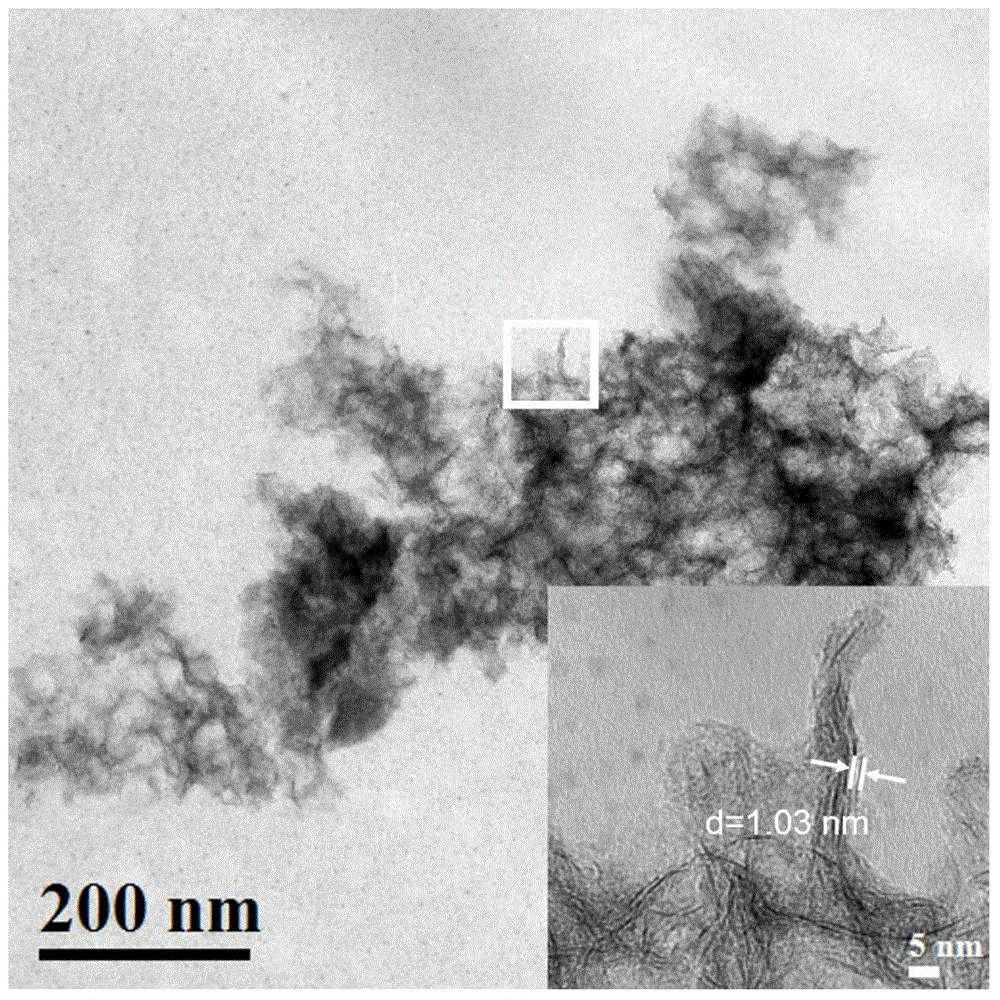

[0041] A lithium ion battery negative electrode material molybdenum disulfide / carbon (MoS 2 / C), the reaction raw material consists of ammonium tetrathiomolybdate 0.250g, cetyltrimethylammonium bromide 0.050g, silicon dioxide nanosphere 0.100g (the ratio of the amount of the three substances is 1:0.143:1.733 ) and absolute ethanol 30ml to prepare MoS 2 / C reaction raw material;

[0042] 1) The MoS 2 The reaction raw materials of the / C composite material are stirred at room temperature until the solvent is completely evaporated, and the remaining powder is dried at 50-65°C;

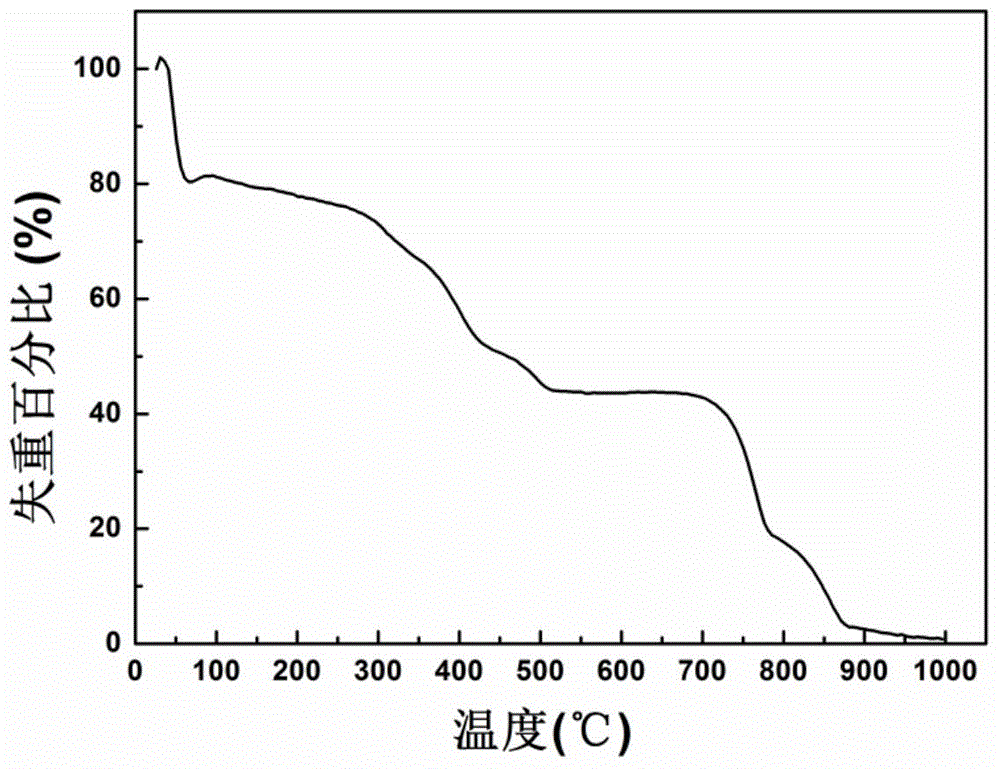

[0043] 2) Place the dried powder described in step 1) in a mixed atmosphere with a volume ratio of argon and hydrogen of 9.5:0.5, heat it in a tube furnace at 700-800°C for 4 hours, and cool naturally to room temperature to obtain a black powder ;

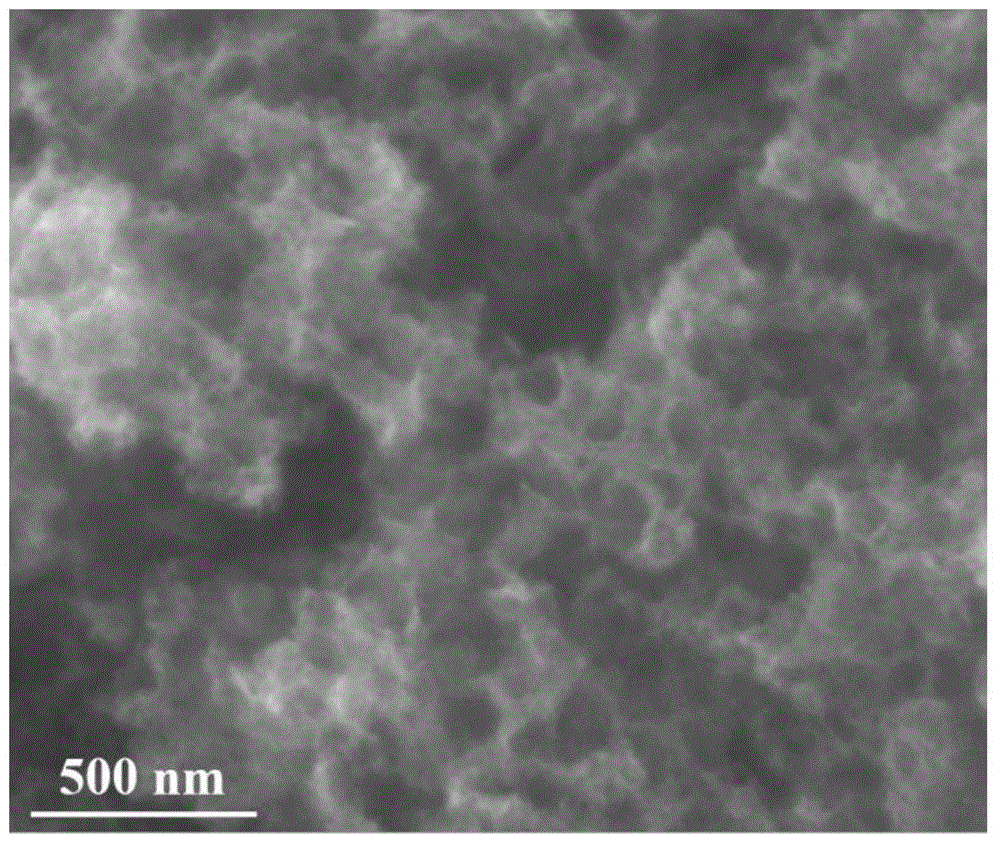

[0044] 3) Treat the black powder described in step 3 with a concentration of 5 to 6% hydrofluoric acid to remove SiO 2 , the final product MoS was obtaine...

Embodiment 2

[0053] The difference between this embodiment and Example 1 is that the reaction raw materials are: ammonium tetrathiomolybdate 0.250g, cetyltrimethylammonium bromide 0.100g, silica nanospheres 0.100g (the amount of the three substances The ratio is 1:0.286:1.733) and absolute ethanol 30ml, and others are identical with embodiment 1.

Embodiment 3

[0055] This embodiment is different from Example 1 in that in step 1, ammonium tetrathiomolybdate 0.250g, cetyltrimethylammonium bromide 0.150g, silica nanosphere 0.100g (the amount of the three substances Ratio is 1:0.429:1.733) and absolute ethanol 30ml, other is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com