Processing technology of dried tangerine peel extract without bitter taste

A technology of tangerine peel extract and processing technology, applied in the directions of food ingredients containing natural extracts, food extraction, food science, etc., can solve the problems affecting the use of tangerine peel extract, bitter taste, low yield, etc., and achieve a fresh and pleasant aroma , good taste, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Extraction: Add 1500ml of water to 100g tangerine peel, extract at 78°C for 58min, then cool down and control the constant temperature at 60°C, add dilute hydrochloric acid to adjust the pH of the system to 4.0, and then obtain the tangerine peel extract;

[0023] (2) Enzymatic hydrolysis: add 3.5 g of pectinase to the tangerine peel extract, the enzymatic hydrolysis temperature is 56°C, and the enzymatic hydrolysis time is 40 minutes. After the enzymatic hydrolysis is completed, the solution is heated to 85°C and kept for 5 minutes;

[0024] (3) Filtration and centrifugation: filter the solution obtained in step (2), and then cool the filtered filtrate, and the temperature after cooling is 25°C, then let the cooled solution stand for 35 minutes, and finally take it to stand still Centrifuge the supernatant of the liquid to obtain the centrifugal liquid;

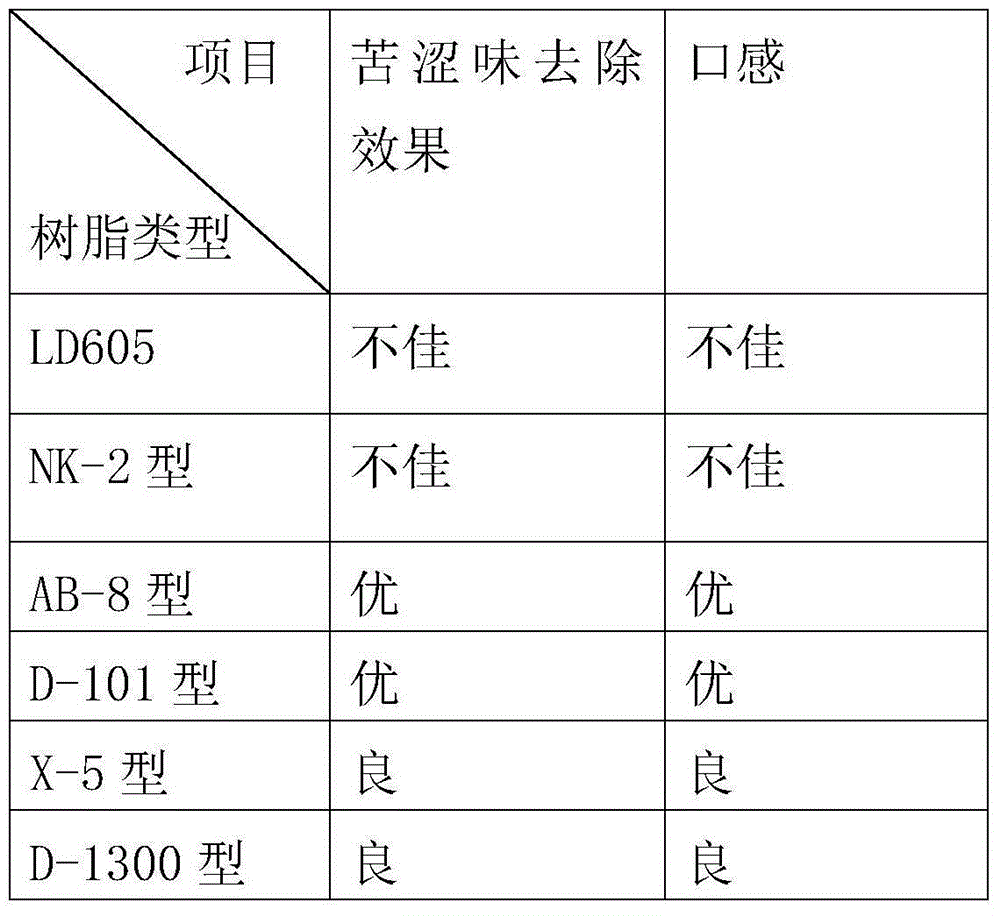

[0025] (4) Dialysis and purification: the centrifugal liquid obtained in step (3) enters the chromatographic column fi...

Embodiment 2

[0030] (1) Extraction: Add 1200ml of water to 100g of tangerine peel, extract at 76°C for 60min, then cool down and control the constant temperature at 58°C, add dilute sulfuric acid to adjust the pH of the system to 4.5 to obtain the tangerine peel extract;

[0031] (2) Enzymatic hydrolysis: add 3.6 g of pectinase into the tangerine peel extract, the enzymatic hydrolysis temperature is 58°C, and the enzymatic hydrolysis time is 45 minutes. After the enzymatic hydrolysis is completed, the solution is heated to 80°C and kept for 10 minutes;

[0032] (3) Filtration and centrifugation: filter the solution obtained in step (2), and then cool the filtrate obtained by the filtration, and the temperature after cooling is 20°C, then let the cooled solution stand for 40 minutes, and finally take it to stand still Centrifuge the supernatant of the liquid to obtain the centrifugal liquid;

[0033] (4) Dialysis and purification: the centrifugal fluid obtained in step (3) enters the chromatograph...

Embodiment 3

[0038] (1) Extraction: Add 1300ml of water to 100g of tangerine peel, extract at 77°C for 65min, then cool down and keep the constant temperature at 59°C, add dilute hydrochloric acid to adjust the pH of the system to 4.5 to obtain the tangerine peel extract;

[0039] (2) Enzymatic hydrolysis: Add 3.7g of pectinase to the tangerine peel extract, the enzymatic hydrolysis temperature is 58°C, and the enzymatic hydrolysis time is 43min. After the enzymatic hydrolysis is completed, the solution is heated to 83°C and kept for 12min;

[0040] (3) Filtration and centrifugation: filter the solution obtained in step (2), and then cool the filtrate obtained by filtration, and the temperature after cooling is 18°C, then let the cooled solution stand for 45 minutes, and finally take it to stand still Centrifuge the supernatant of the liquid to obtain the centrifugal liquid;

[0041] (4) Dialysis purification: the centrifugal liquid obtained in step (3) enters the chromatography column filled wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com