Natural environment-friendly wet tissue

A natural and environmentally friendly technology for wet wipes, applied in cosmetics, textiles, papermaking, non-woven fabrics, etc., can solve the problems of weakened disinfection effect of wet wipes and inability to effectively inhibit bacterial growth, achieving soft texture, saving energy and cost, Safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A natural and environmentally friendly wet wipes, 80% bamboo fiber, 10% mint fiber, 10% Acetobacter xylinum fiber.

[0027] A preparation method of natural environment-friendly wet wipes, comprising the following steps:

[0028] (1) Clean the bamboo fiber, mint fiber and Acetobacter xylinum fiber, break them up, and obtain a mixed fiber with a fiber length of 15 mm;

[0029] (2) Reinforce and dry the mixed fibers according to the conventional spunlace operation process to obtain a natural and environmentally friendly non-woven fabric with a density of 55g / m 2 ;

[0030] (3) Divide the natural environmental protection non-woven fabric, do not need to add antibacterial agent and preservative when soaking, soak to saturation, and carry out ultraviolet radiation;

[0031] (4) Packaging, inventory.

[0032] Soaking solution: vitamin E0.3%, vitamin B50.3%, sesame oil 0.2%, honey 0.5%, fruit acid 0.2%, glycerin 1.5%, purified water 97%.

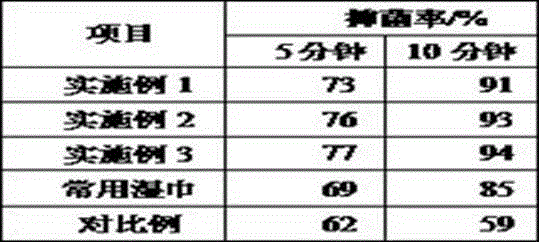

[0033] The natural environment-fri...

Embodiment 2

[0035] A natural and environmentally friendly wet wipes, 83% bamboo fiber, 10% mint fiber, 7% Acetobacter xylinum fiber.

[0036] A preparation method of natural environment-friendly wet wipes, comprising the following steps:

[0037] (1) Clean the bamboo fiber, mint fiber and Acetobacter xylinum fiber, break them up, and obtain a mixed fiber with a fiber length of 16 mm;

[0038] (2) Reinforce and dry the mixed fibers according to the conventional spunlace operation process to obtain a natural and environmentally friendly non-woven fabric with a density of 57g / m 2 ;

[0039] (3) Divide the natural environmental protection non-woven fabric, do not need to add antibacterial agent and preservative when soaking, soak to saturation, and carry out ultraviolet radiation;

[0040] (4) Packaging, inventory.

[0041] Soaking solution: 0.4% vitamin E, 50.4% vitamin B, 0.2% sesame oil, 0.5% honey, 0.2% fruit acid, 2% glycerin, 96.3% purified water.

[0042] The natural environment-fr...

Embodiment 3

[0044] A natural and environmentally friendly wet wipes, 85% bamboo fiber, 10% mint fiber, 5% Acetobacter xylinum fiber.

[0045] A preparation method of natural environment-friendly wet wipes, comprising the following steps:

[0046] (1) Clean the bamboo fiber, mint fiber and Acetobacter xylinum fiber, break them up, and obtain a mixed fiber with a fiber length of 18 mm;

[0047] (2) Reinforce and dry the mixed fibers according to the conventional spunlace operation process to obtain a natural and environmentally friendly non-woven fabric with a density of 58g / m 2 ;

[0048] (3) Divide the natural environmental protection non-woven fabric, do not need to add antibacterial agent and preservative when soaking, soak to saturation, and carry out ultraviolet radiation;

[0049] (4) Packaging, inventory.

[0050] Soaking solution: vitamin E0.4%, vitamin B50.4%, sesame oil 0.3%, honey 0.5%, fruit acid 0.3%, glycerin 2%, purified water 96.1%.

[0051] The natural environment-frie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com