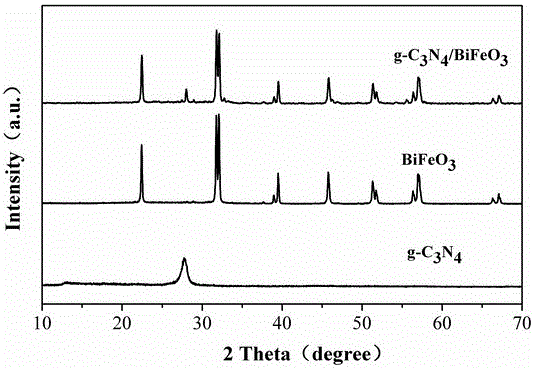

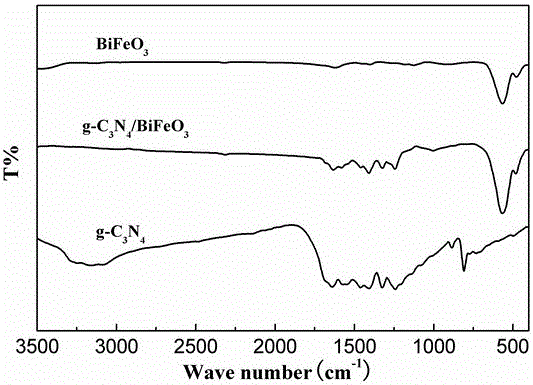

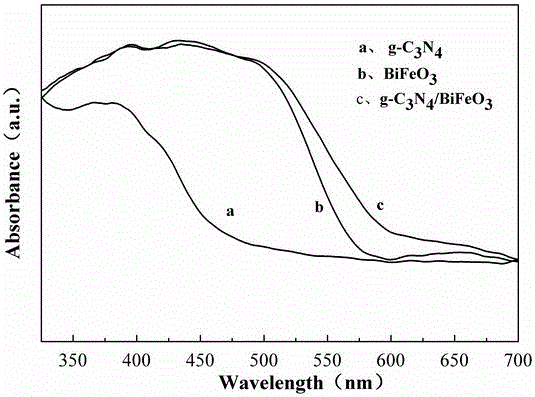

Preparation and application of composite photocatalyst g-C3N4-BiFeO3 for efficiently removing persistent organic pollutants

A technology of organic pollutants, g-c3n4-, applied in the direction of physical/chemical process catalysts, water pollutants, chemical instruments and methods, etc., can solve the problems of limitations, low photocatalytic activity, etc., and achieve good repeatability and raw materials Rich, easy to obtain, and convenient for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] g-C 3 N 4 -The preparation method of bismuth ferrite composite photocatalyst, this method comprises:

[0027] (1) dissolving bismuth salt and iron salt in an organic solvent respectively to form an organic solution containing bismuth salt and an organic solution containing iron salt;

[0028] (2) fully mixing the organic solution containing bismuth salt and the organic solution containing iron salt in the same proportion in (1), and magnetically stirring for a certain period of time to form a mixed organic solution containing bismuth salt and iron salt;

[0029] (3) Add a certain amount of melamine into the mixed solution of (2);

[0030] (4) Evaporating the mixed organic solution in (3) to dryness to obtain a xerogel;

[0031] (5) Grind the xerogel in (4) into powder, transfer it to a muffle furnace for calcination, cool to room temperature, and grind to obtain a sample:

[0032] The bismuth salt described in step (1) is bismuth nitrate and its hydrate, the iron sa...

Embodiment 1

[0039] First weigh 0.005mol of Bi(NO 3 ) 3 ·5H 2 O and 0.005molFe(NO 3 ) 3 9H 2 The O samples were dissolved in 30ml of ethylene glycol methyl ether solution, dissolved evenly under magnetic stirring at room temperature, and the Bi(NO 3) 3 Ethylene glycol methyl ether solution and 0.005molFe(NO 3 ) 3 Mix the ethylene glycol methyl ether solution, stir magnetically at room temperature for 30 minutes, add 0.01 mol of melamine, dissolve evenly, heat and stir until it is in the form of a sol, transfer the sample in the form of a sol to an oven for 24 hours to dry at 90°C, and obtain a gel. Grind the gel into powder and transfer it to a muffle furnace for calcination at 550°C for 4 hours, cool to room temperature, and grind to obtain a sample. Weigh 0.100g of the above-mentioned catalyst, add it to 100mL of bisphenol A organic pollutants with an initial concentration of 10mg / L, and carry out photodegradation after 40 minutes of dark reaction. The power of the light source i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com