Magnesium-based amorphous alloy solder used for magnesium alloy brazing and preparation method for magnesium-based amorphous alloy solder

A technology of amorphous alloy and magnesium alloy, applied in welding equipment, metal processing equipment, welding/cutting medium/material, etc., can solve the problems of low strength and high melting point, and achieve the effect of less impurity content and good composition control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

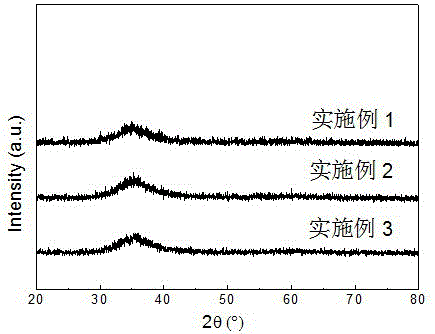

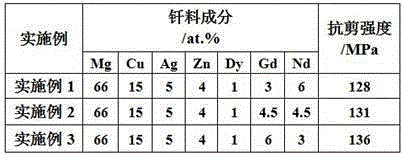

[0024] Embodiment 1, Mg 66 Cu 15 Ag 5 Zn 4 Dy 1 Gd 3 Nd 6 Amorphous Alloy Solder

[0025] The first step, according to Mg 66 Cu 15 Ag 5 Zn 4 Dy 1 Gd 3 Nd 6 Prepare Mg, Cu, Ag, Zn, Dy, Gd and Nd raw materials according to the ratio; the purity of the above-mentioned Mg, Cu, Ag, Zn, Dy, Gd and Nd raw materials are all above 99.9%.

[0026] The second step is to put the raw material of the first step into a graphite crucible and melt it in a high-frequency induction heating furnace. The whole melting is carried out in a sealed chamber with a pure argon atmosphere, the purity of the atmosphere is greater than 99.99%, and the atmosphere pressure is 1 atmosphere. The current is 150 amperes for the first 10 minutes, 500 amperes for the next 20 minutes, and 300 amperes for the last 20 minutes, thereby fully melting and homogenizing the raw materials.

[0027] The third step is to pour the alloy melt obtained in the second step into a copper mold with an inner diameter of...

Embodiment 2

[0029] Example 2, Mg 66 Cu 15 Ag 5 Zn 4 Dy 1 Gd 4.5 Nd 4.5 Amorphous Alloy Solder

[0030] The first step, according to Mg 66 Cu 15 Ag 5 Zn 4 Dy 1 Gd 4.5 Nd4.5 Prepare Mg, Cu, Ag, Zn, Dy, Gd and Nd raw materials according to the ratio; the purity of the above-mentioned Mg, Cu, Ag, Zn, Dy, Gd and Nd raw materials are all above 99.9%.

[0031] The second step is to put the raw materials of the first step into a graphite crucible and melt them in a high-frequency induction heating furnace. The whole melting is carried out in a sealed chamber with a pure argon atmosphere. The purity of the atmosphere is greater than 99.99%, and the atmosphere pressure is 1 atmosphere. The current is 150 amperes for the first 10 minutes, 500 amperes for the next 20 minutes, and 300 amperes for the last 20 minutes, thereby fully melting and homogenizing the raw materials.

[0032] The third step is to pour the alloy melt obtained in the second step into a copper mold with an inner diame...

Embodiment 3

[0034] Embodiment 3, Mg 66 Cu 15 Ag 5 Zn 4 Dy 1 Gd 6 Nd 3 Amorphous Alloy Solder

[0035] The first step, according to Mg 66 Cu 15 Ag 5 Zn 4 Dy 1 Gd 6 Nd 3 Prepare Mg, Cu, Ag, Zn, Dy, Gd and Nd raw materials according to the ratio; the purity of the above-mentioned Mg, Cu, Ag, Zn, Dy, Gd and Nd raw materials are all above 99.9%.

[0036] The second step is to put the raw materials of the first step into a graphite crucible and melt them in a high-frequency induction heating furnace. The whole melting is carried out in a sealed chamber with a pure argon atmosphere. The purity of the atmosphere is greater than 99.99%, and the atmosphere pressure is 1 atmosphere. The current is 150 amperes for the first 10 minutes, 500 amperes for the next 20 minutes, and 300 amperes for the last 20 minutes, thereby fully melting and homogenizing the raw materials.

[0037] The third step is to pour the alloy melt obtained in the second step into a copper mold with an inner diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com