Making method of heat-insulation anticorrosive polytetrafluoroethylene membrane

A technology of polytetrafluoroethylene and anti-corrosion film, which is applied in the fields of pipelines, polytetrafluoroethylene heat-insulating anti-corrosion film materials and their preparation, equipment heat-insulation and heat-insulation outer protection materials, pipe fittings, and detachable heat-insulation and heat-insulation sleeves, and can solve the problem of glass fiber reinforced plastics Poor aging resistance, high manufacturing cost, and no good solutions have been proposed to achieve the effects of ensuring surface compactness, improving peeling performance, and improving heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

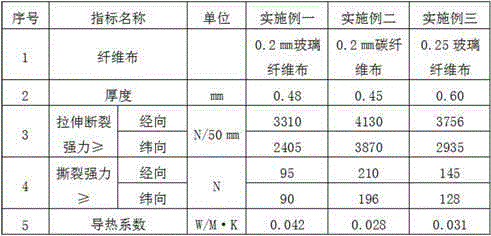

Embodiment 1

[0027] ⑴The bottom layer is formed by dipping on one side. The PTFE bottom layer dispersion is proportioned by weight percentage: 10% PTFE emulsion with a solid content of 60%, 0.5% KH550 silane coupling agent, and 89.5% deionized water. Add PTFE emulsion, silane coupling agent and deionized water into the container, stir at a speed of 80 rpm, and stir until the components are evenly dispersed; add the PTFE bottom dispersion liquid into the trough of the impregnation equipment, and then pour the glass with a thickness of 0.2mm The fiber cloth is wound on the transmission shaft of the impregnation equipment, and then half-wrapped on the impregnation roller in the trough, so that one side of the fiber cloth is in contact with the PTFE bottom layer dispersion liquid for single-side impregnation treatment, and the thickness of the bottom layer is controlled by the thickness adjustment roller. Enter the oven, pass through the first and second zones of the oven in turn, the oven is ...

Embodiment 2

[0029]⑴The bottom layer is formed by dipping on one side. The PTFE bottom layer dispersion is proportioned by weight percentage: 20% PTFE emulsion with a solid content of 60%, 0.8% KH550 silane coupling agent, 1% JTW titanate coupling agent, and 78.2% deionized water. Add PTEE emulsion, coupling agent and deionized water into the container, stir at a speed of 80 rpm, and stir until the components are evenly dispersed; add the PTFE bottom dispersion liquid into the trough of the impregnation equipment, and then add the plain carbon fiber with a thickness of 0.2mm The fine cloth is wound on the transmission shaft of the impregnation equipment, and then half-wrapped on the impregnation roller in the trough, so that one side of the fiber cloth is in contact with the PTFE bottom layer dispersion liquid for single-side impregnation treatment, and the thickness of the bottom layer is controlled by the thickness adjustment roller. Oven, passing through the first and second zones of th...

Embodiment 3

[0030] ⑴The bottom layer is formed by dipping on one side. The PTFE bottom layer dispersion liquid is proportioned by weight percentage: 25% PTFE emulsion with a solid content of 60%, 0.2% KH550 silane coupling agent, 0.3% JTW18 aluminate coupling agent, and 74.5% deionized water. Add the PTFE emulsion, coupling agent and deionized water into the container, stir at a speed of 80 rpm, and stir until the components are evenly dispersed; add the PTFE bottom dispersion liquid into the trough of the impregnation equipment, and then add the glass fiber with a thickness of 0.25mm The cloth is wound on the transmission shaft of the impregnating equipment, and then half-wrapped on the impregnating roller in the trough, so that one side of the fiber cloth is in contact with the PTFE bottom layer dispersion liquid for single-side impregnation treatment, and the impregnation thickness of the bottom layer is controlled by the thickness adjusting roller, and then enters Oven, passing throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com