A kind of hemp concentrated protein powder rich in cannabidiol and preparation method thereof

A technology of concentrating protein powder and cannabidiol, which is applied in the field of protein powder, can solve the problems of cannabidiol exploration and other problems, and achieve the effect of good market prospect, enhanced contact area and good color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

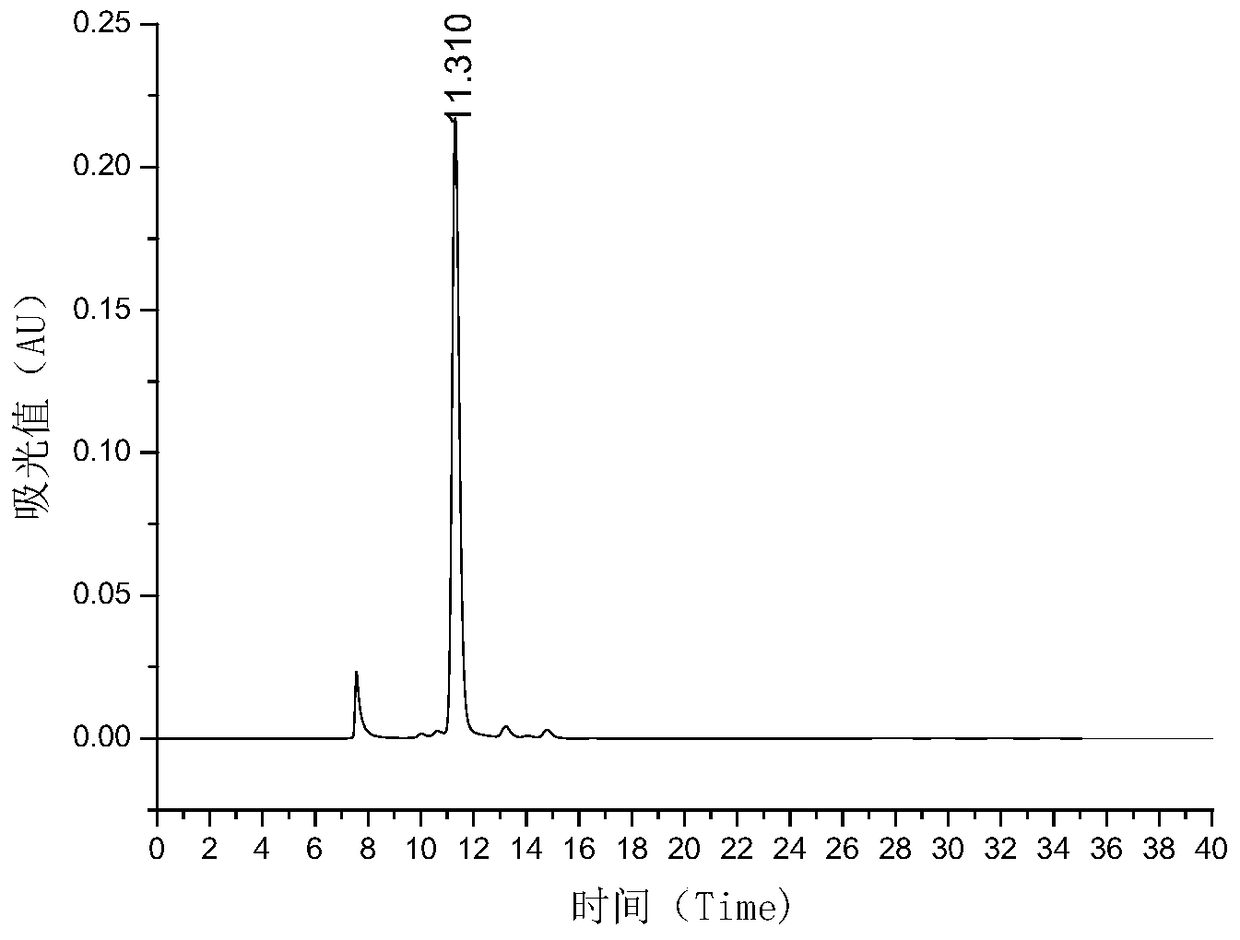

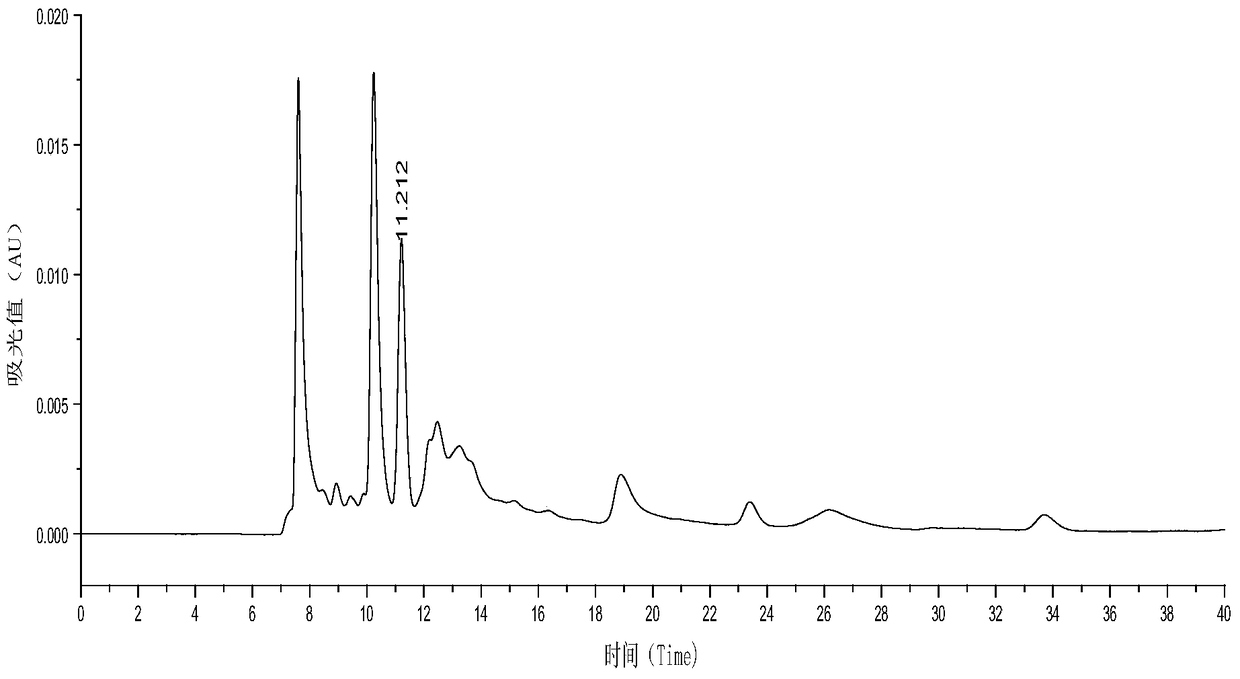

[0040] 1) Preparation of sample solution

[0041] Accurately weigh 1.0 g of protein product, add appropriate amount of distilled water to make a 5% solution, add 0.1 g of papain, fully hydrolyze in a water bath at 50°C for 1.0 h, and then lyophilize. Add 20.0 mL of methanol to the lyophilized protein, and ultrasonic bath for 20 min. Take 0.5 mL of the standing supernatant and perform silica gel column chromatography to remove impurities, using petroleum ether-diethyl ether (v / v 8:2) as the eluent, and collect the liquid obtained through the column. Dry the liquid with nitrogen flow, dissolve it in 1.5 mL of methanol, pass it through a 0.22 μm organic membrane in an ultrasonic bath for 5 min, and store the obtained filtrate in a refrigerator for later use.

[0042] 2) Drawing of CBD standard curve

[0043] Use Merck C18 column, Waters2487 high-performance liquid chromatograph to measure. The conditions used are as follows: the wavelength is 220nm, the column temperature is 2...

Embodiment 1

[0047] Get denatured hemp meal 2.0kg (this denatured hemp meal is the by-product in the process of extracting hemp oil at high temperature, the main component protein content is 63.69%, fiber content is 13.52%, fat content is 1.09%), is placed in stainless steel tank, according to material Add 20.0L of industrial water at a liquid ratio of 1:10 (Kg / L), and stir mechanically at room temperature to mix evenly. While stirring, NaOH lye with a mass concentration of 10% was added until the pH value was 9.0, and the stirring was continued at room temperature for 40 min. Then transfer to a vertical colloid mill, and carry out 20min grinding process at a rotating speed of 4000r / min. The above-mentioned feed liquid is transferred into the jet cooker system, and the processing temperature is set at 130° C., and the processing time is 120 s. Then transfer to a horizontal centrifuge with a temperature of 25° C. and a rotational speed of 3000 r / min for 20 minutes of centrifugation. The s...

Embodiment 2

[0052] Take 1.0kg of denatured hemp meal, put it in an aluminum tank, add 15.0L of industrial water according to the material-to-liquid ratio of 1:15 (Kg / L), and manually stir and mix evenly at room temperature. Add 10% lye while stirring until the pH value is 9.5, and keep stirring at room temperature for 45 minutes. Then transfer to the split type colloid mill, and carry out 20min grinding process at a rotating speed of 4500r / min. The above feed liquid is transferred into the jet cooker system, the processing temperature is set at 135°C, and the processing time is 120s. Then transfer to a horizontal centrifuge with a temperature of 25° C. and a rotational speed of 3000 r / min for centrifugation for 15 minutes. The supernatant was transferred to a stainless steel ultrafiltration membrane system with a membrane pore size of 100nm for ultrafiltration at 35°C, the inlet pressure was 0.3MPa, the outlet pressure was 0.3MPa, and the flow rate of the permeate was 2.0L / min for cyclic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com