Extraction process and application of peach gum polysaccharide

The technology of peach gum polysaccharide and peach gum is applied in the field of plant polysaccharide and the field of biomedicine, and can solve the problems of inability to meet the application requirements of medicines, content of peach gum polysaccharide, and difficulty in industrialized production, and achieve high yield, lower blood sugar, and loss of small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] According to one aspect of the present invention, a kind of preparation method of peach gum polysaccharide is provided, it is characterized in that, comprises the following steps:

[0036] (1) Remove impurities from natural peach gum, and swell it with water at a ratio of 0.5-1.5:100 to obtain a suspension, heat and dissolve the suspension, filter and centrifuge to obtain a supernatant; the temperature is preferably 90-100°C;

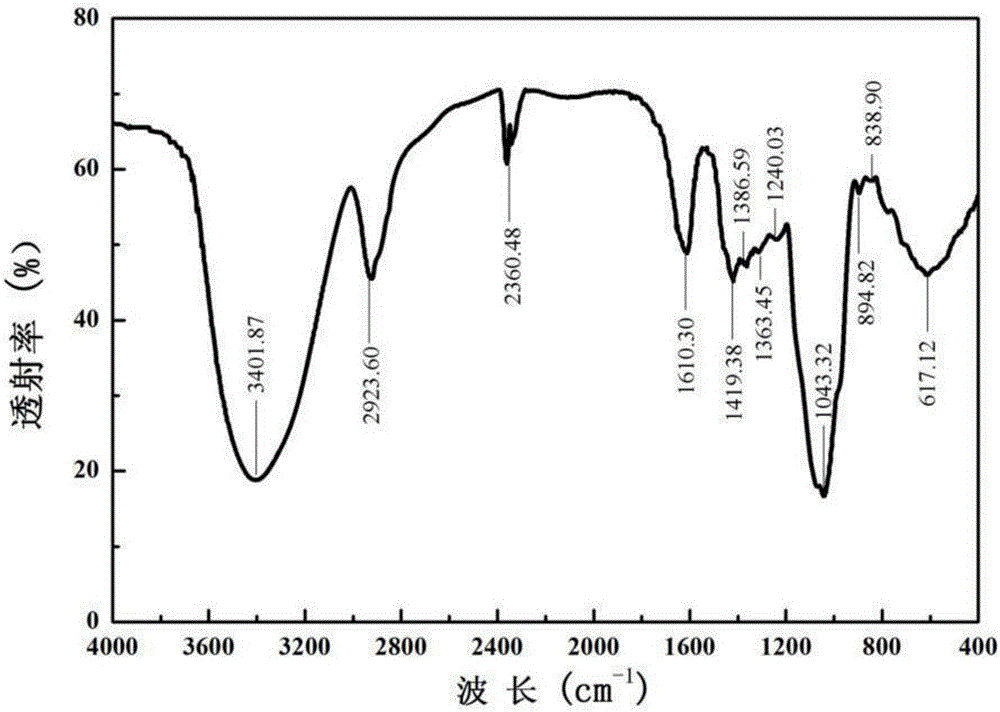

[0037] (2) Concentrating the supernatant, ethanol alcohol precipitation to obtain a precipitate, dissolving the precipitate in water, purifying, taking the supernatant, fading, concentrating and drying to obtain peach gum crude polysaccharide;

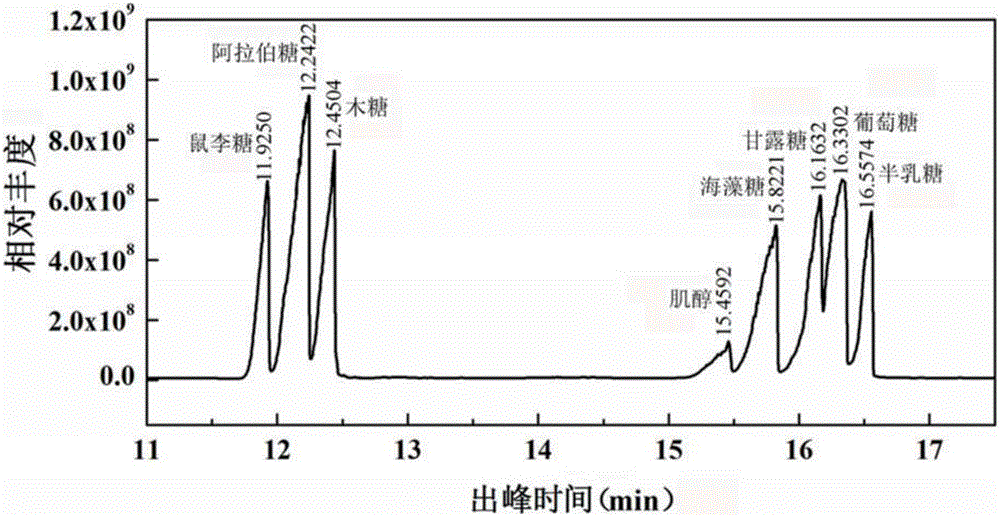

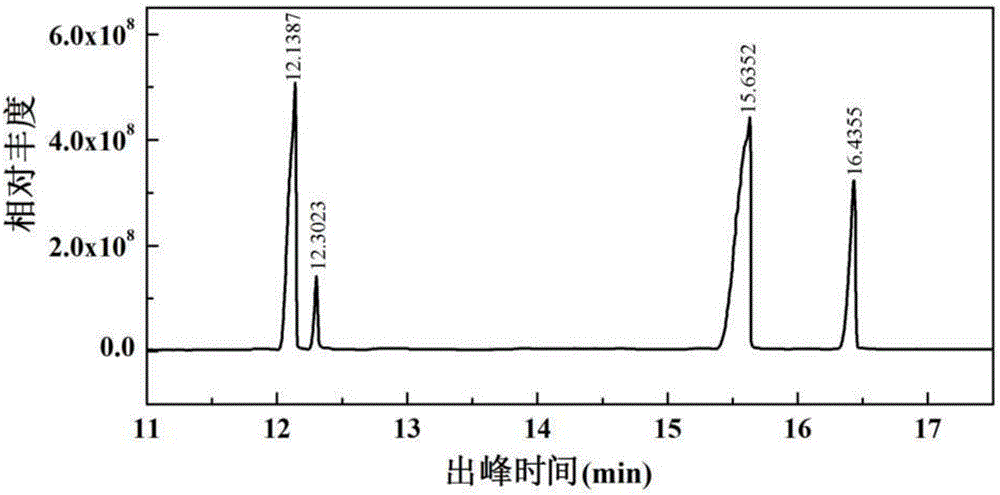

[0038] (3) The peach gum crude polysaccharide is configured into an aqueous solution with a mass volume ratio of 5%-12%, passes through a DEAE cellulose column, and is eluted with a water solvent eluent of 0.3mol / L-0.7mol / L. - Collect the polysaccharide solution within 16 hours;

[0039] (4) The collect...

Embodiment 1

[0054] (1) Remove impurities from the raw peach gum, swell at a material-to-liquid ratio of 1:100, and then dissolve at 100°C for 25-30 hours. Filter the obtained peach gum solution with four layers of gauze to remove impurities such as undissolved peach gum and bark for the first time; centrifuge the obtained supernatant at 3000rpm / min, and remove impurities such as dust for the second time.

[0055] (2) Concentrate the collected supernatant to about 1 / 4 of the original volume with a vacuum rotary evaporator, and carry out alcohol precipitation with ethanol overnight, and the obtained precipitate is crude polysaccharide. The crude polysaccharide was dissolved again in water, and the protein was removed by Sevage method. This process was repeated 3-4 times until the middle layer was clarified. Mix the resulting deproteoglycan solution and concentrate it with 30% H 2 o 2 For fading, stir evenly, leave it for several hours until the color is stable, and the fading is over. Co...

Embodiment 2

[0059] (1) Remove impurities from raw peach gum, swell at a solid-liquid ratio of 0.5:100, and then dissolve at 90°C for 25-30h. Filter the obtained peach gum solution with four layers of gauze to remove impurities such as undissolved peach gum and bark for the first time; centrifuge the obtained supernatant at 2000 rpm / min, and remove impurities such as dust for the second time.

[0060] (2) Concentrate the collected supernatant to about 1 / 4 of the original volume with a vacuum rotary evaporator, and carry out alcohol precipitation with ethanol overnight, and the obtained precipitate is crude polysaccharide. The crude polysaccharide was dissolved again in water, and the protein was removed by Sevage method. This process was repeated 3-4 times until the middle layer was clarified. Mix the resulting deproteoglycan solution and concentrate it with 30% H 2 o 2 For fading, stir evenly, leave it for several hours until the color is stable, and the fading is over. Concentrate to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com