Organic fluorine-silicon light-cured resin and preparation method therefor and application thereof

A light curing resin and curing resin technology, applied in the field of light curing, can solve the problems of low surface tension, weak force, small force, etc., to achieve low surface tension, strong wipe resistance and thermal stability, strong self-cleaning performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Synthesis of Embodiment 1 Organic Fluorosilicone Photocurable Resin 1

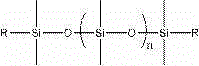

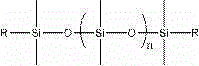

[0041] (1) 20kg of hydroxyalkyl polysiloxane ( , n=28, R is -CH 2 CH 2 CH 2 OH), 9kg of isophorone diisocyanate, and 0.01kg of organotin catalyst were put into a reactor equipped with a stirrer, dropping funnel and thermometer, heated and stirred to 45°C under nitrogen protection, and kept for 2.0 hours;

[0042] (2) At 65°C, add 20kg of fluorocarbon resin and keep it warm for 2.0 hours; then add 10kg of hydroxyethyl acrylate and 0.04kg of p-methoxyphenol and react for 2 hours to obtain an organofluorosilicon photocurable resin.

Embodiment 2

[0043] Synthesis of Embodiment 2 Organic Fluorosilicone Photocurable Resin 2

[0044] (1) 20kg of hydroxyalkyl polysiloxane ( , n=28, R is -CH 2 CH 2 CH 2 OH), 9kg of isophorone diisocyanate, and 0.01kg of organotin catalyst were loaded into a reactor equipped with a stirrer, dropping funnel and thermometer, heated and stirred to 45°C under nitrogen protection, and kept for 2.0 hours;

[0045] (2) At 65°C, add 20kg of fluorocarbon resin and keep it warm for 2.0 hours; then add 20kg of trimethylolpropane triacrylate and 0.04kg of p-methoxyphenol and react for 2 hours to obtain organofluorosilicon Light curing resin.

Embodiment 3

[0046] Embodiment 3 Synthesis of organofluorosilicon photocurable resin 3

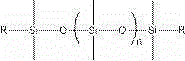

[0047] (1) 60kg of hydroxyalkyl polysiloxane ( , n=28, R is -CH 2 CH 2 CH 2 CH 2 OH), 27kg of isophorone diisocyanate, and 0.45kg of organotin catalyst were loaded into a reactor equipped with a stirrer, dropping funnel and thermometer, heated and stirred to 45°C under nitrogen protection, and kept for 2.0 hours;

[0048] (2) At 65°C, add 30kg of fluorocarbon resin and keep it warm for 2.0 hours; then add 20kg of hydroxyethyl acrylate and 0.16kg of p-methoxyphenol and react for 2 hours to obtain an organofluorosilicon photocurable resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com