Engineering bacterium capable of producing D-lactate by aid of pentose and hexose synchronously by means of fermentation, and fabrication and application of engineering bacterium

A technology of engineering bacteria and six-carbon sugar, applied in the fields of genetic engineering and fermentation engineering, can solve the problems of low conversion efficiency, low product purity, low fermentation yield, etc., and achieves reduced glucose effect, high product purity, and ethanol. high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

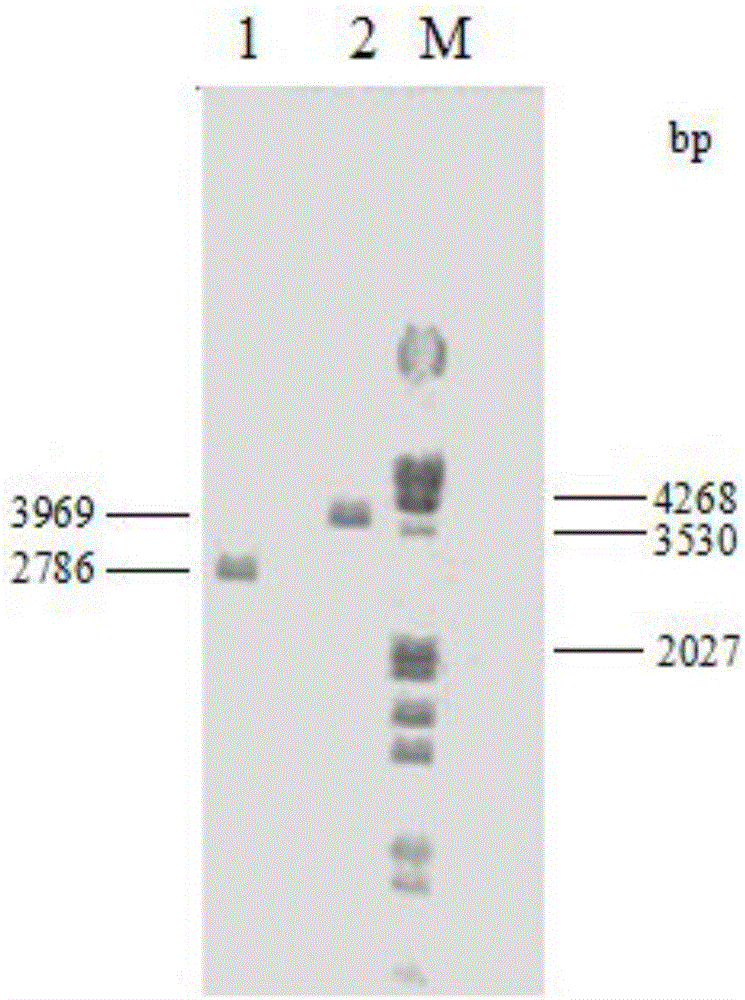

[0039] Embodiment 1 Utilizes the construction of xylose-producing D-lactic acid Escherichia coli engineering bacteria E.coliDX02

[0040] Utilizing xylose to produce D-lactic acid Escherichia coli engineering bacteria E.coliDX02 is the starting strain of Escherichia coli engineering bacteria RM10 that can ferment xylose to produce ethanol. Through homologous recombination technology, the D-lactate dehydrogenase gene (ldhA) The alcohol dehydrogenase gene (adhE) was replaced to obtain the engineering bacterium E.coliDX02.

[0041] E.coliRM10 is derived from the wild strain E.coliB (ATCC11303), which knocked out pyruvate formate lyase (focA-pflB), fumarate reductase (frdBC), acetate kinase (ackA), D-lactate Genes of key enzymes of competitive metabolic pathways such as hydrogenase (ldhA) and partial nuclease genes (rngHSR2), and anaerobic expression of pyruvate dehydrogenase (pflBp6-aceEF-lpd), which can efficiently utilize xylose under anaerobic conditions Homofermentation to p...

Embodiment 2

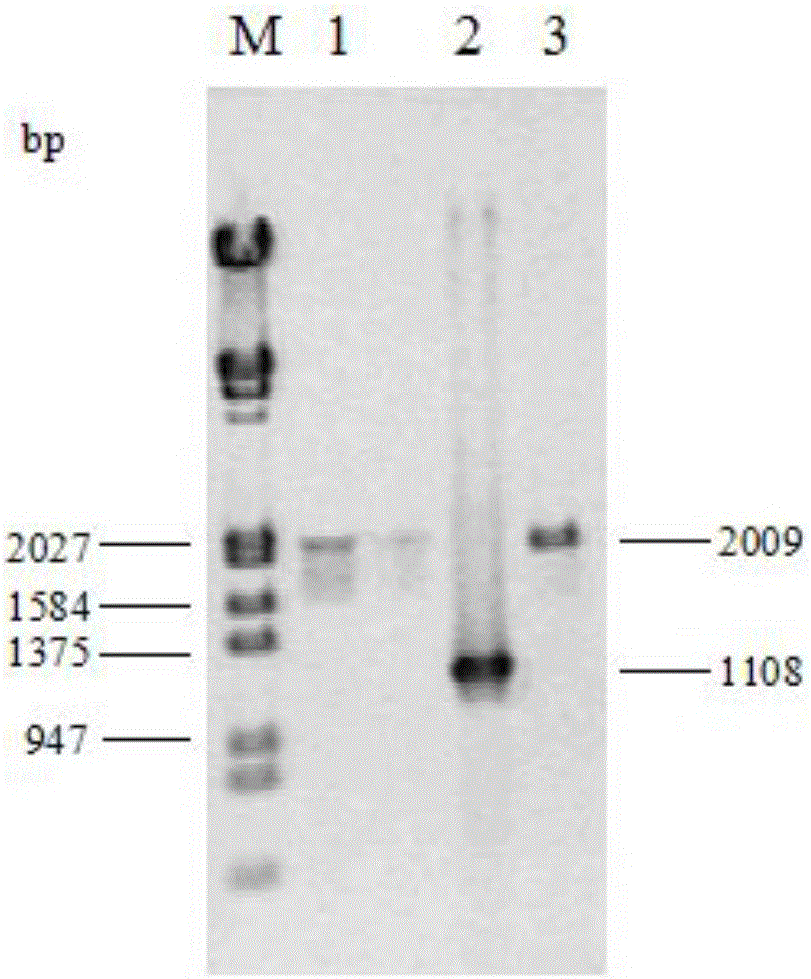

[0056] Example 2 Construction of high-yield optically pure D-lactic acid engineering bacteria E.coliDX03 that can simultaneously utilize five-carbon sugar and six-carbon sugar to ferment

[0057] On the basis of the xylose-utilizing D-lactic acid engineering bacteria E.coliDX02, the ptsG gene was knocked out by using RED homologous recombination technology, and the D-lactic acid engineering bacteria E. coliDX03.

[0058] The first step, amplifying the ptsG homologous recombination fragment: using the pKD4 plasmid as a template, carrying out PCR amplification with primers ptsG-P1 and ptsG-P2 (knockout primers), the PCR product includes the FRT-kan-FRT sequence on the pKD4 plasmid And ptsG gene open reading frame (ORF) first and last 45bp homologous sequence. The amplification system is: 25 μL of ThermoScientific PCR MasterMix 2X buffer, 20 ng of DNA template, 1 μL of each primer (100 μM), 25 μL of sterile water, and the total volume is 50 μL. The amplification conditions were...

Embodiment 3

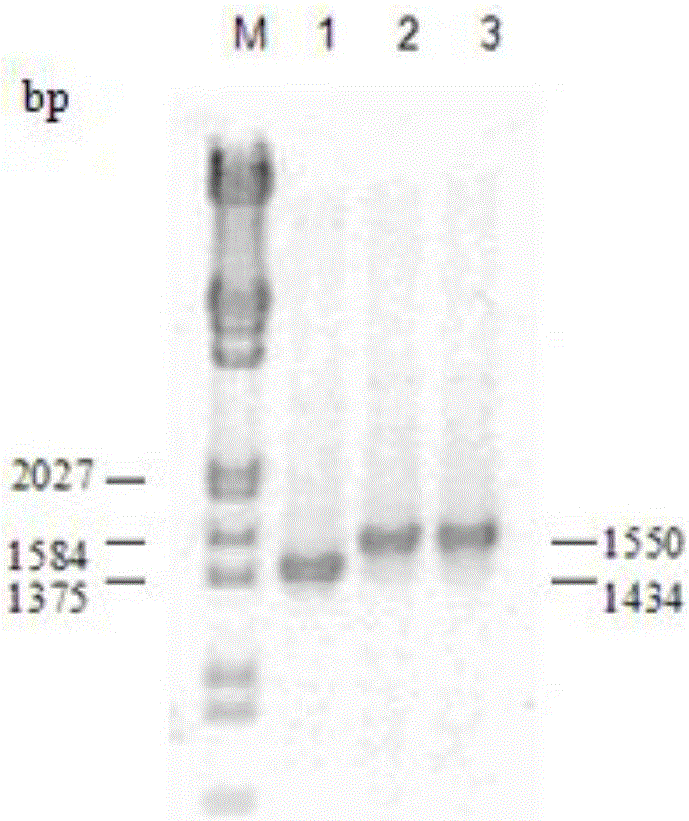

[0067] Example 3 Fermentation of engineering bacteria E.coliDX02 and E.coliDX03 to produce D-lactic acid

[0068] Pick a single colony from the plate, inoculate it into an anaerobic tube containing 10 mL of seed culture solution, and culture overnight at 37°C. Take 2 mL of the bacterial liquid and inoculate it into 300 mL of the seed liquid, and cultivate it at 150 r / min at 37°C until the mid-logarithmic growth phase. Inoculate the bacterial liquid into 3L fermentation medium with an inoculum amount of 10% (v / v), place it in a 7L fermenter SartoriusBB-8846880 (SartoriusStedimBiotech, Germany) with an automatic adjustment system, and cultivate and ferment at 150r / min at 37°C , add 3mol / LCa(OH) 2 Control the pH to 7.0. Different combinations of carbon sources: 10% glucose, 10% xylose, 5% glucose + 5% xylose, 6% glucose + 3% xylose + 1% L-arabinose were used as substrates to culture until the end of fermentation. Samples were taken regularly to measure the concentration of bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com