Flexible ultra-hydrophobic up-conversion luminous thin film and preparation method

A luminescent film and super-hydrophobic technology, applied in the direction of textiles, papermaking, non-woven fabrics, etc., to achieve excellent reusability, reusable performance can be cut, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

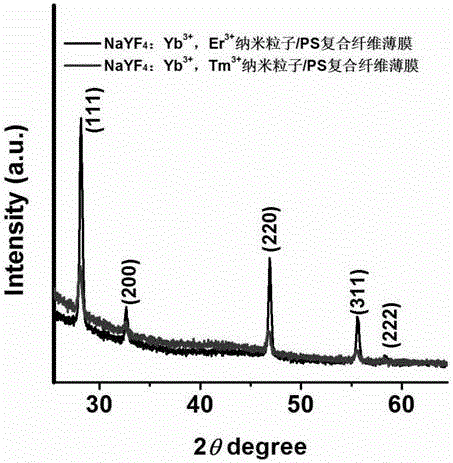

Embodiment 1

[0030] Add 0.48mmol yttrium chloride hexahydrate, 1.2mmol sodium chloride, 0.108mmol ytterbium chloride hexahydrate and 0.012mmol erbium chloride hexahydrate into 9ml ethylene glycol solution, stir magnetically for 30min to obtain solution A; g branched polyethyleneimine PEI and 0.11112 g ammonium fluoride were added to another 6 ml ethylene glycol solution and stirred for 60 min to obtain solution B. Then the prepared solution A and solution B were mixed and stirred for 10 minutes, then the mixed solution was transferred to a high-pressure reactor, sealed and placed in an electric oven for solvothermal reaction at a reaction temperature of 200°C for 120 minutes. After the reaction, the reaction kettle was naturally cooled to room temperature, opened, centrifuged to take out the white product, washed with absolute ethanol for 4 times, and finally the product was vacuum-dried at 60°C for 12 hours to obtain NaYF 4 : Yb 3+ , Er 3+ Upconverting Luminescent Nanoparticles.

[003...

Embodiment 2

[0034] Add 0.48mmol yttrium chloride hexahydrate, 1.2mmol sodium chloride, 0.12mmol ytterbium chloride hexahydrate and 0.0012mmol thulium chloride hexahydrate to 9ml ethylene glycol solution, and magnetically stir for 40min to obtain solution A; g branched polyethyleneimine PEI and 0.11112 g ammonium fluoride were added to another 6 ml ethylene glycol solution and stirred for 80 min to obtain solution B. Then the prepared solution A and solution B were mixed and stirred for 15 minutes, and then the mixed solution was transferred to a high-pressure reactor, sealed and placed in an electric oven for solvothermal reaction at a reaction temperature of 200° C. for 130 minutes. After the reaction, the reaction kettle was naturally cooled to room temperature, opened, centrifuged to take out the white product obtained, washed with absolute ethanol for 4 times, and finally the product was vacuum-dried at 60°C for 10 hours to obtain NaYF 4 : Yb 3+ , Tm 3+ Upconverting Luminescent Nano...

Embodiment 3

[0038] Add 0.48mmol yttrium chloride hexahydrate, 1.2mmol sodium chloride, 0.095mmol ytterbium chloride hexahydrate and 0.022mmol erbium chloride hexahydrate into 9ml of ethylene glycol solution, stir magnetically for 50min to obtain solution A; g branched polyethyleneimine PEI and 0.11112 g ammonium fluoride were added to another 6 ml ethylene glycol solution and stirred for 60 min to obtain solution B. Then the prepared solution A and solution B were mixed and stirred for 20 minutes, then the mixed solution was transferred to a high-pressure reactor, sealed and placed in an electric oven for solvothermal reaction at a reaction temperature of 205° C. for 140 minutes. After the reaction, the reaction kettle was naturally cooled to room temperature, opened, centrifuged to take out the white product obtained, washed with absolute ethanol for 4 times, and finally the product was vacuum-dried at 60°C for 8 hours to obtain NaYF 4 : Yb 3+ , Er 3+ Upconverting Luminescent Nanoparti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com