Method for preparing titanium-diboride-based ceramic composite material

A technology of ceramic composite materials and titanium diboride, which is applied in the field of ceramic materials, can solve the problems of low density, deformation, and high cost of hot pressing, and achieve the effects of excellent properties, simple method steps, and low temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

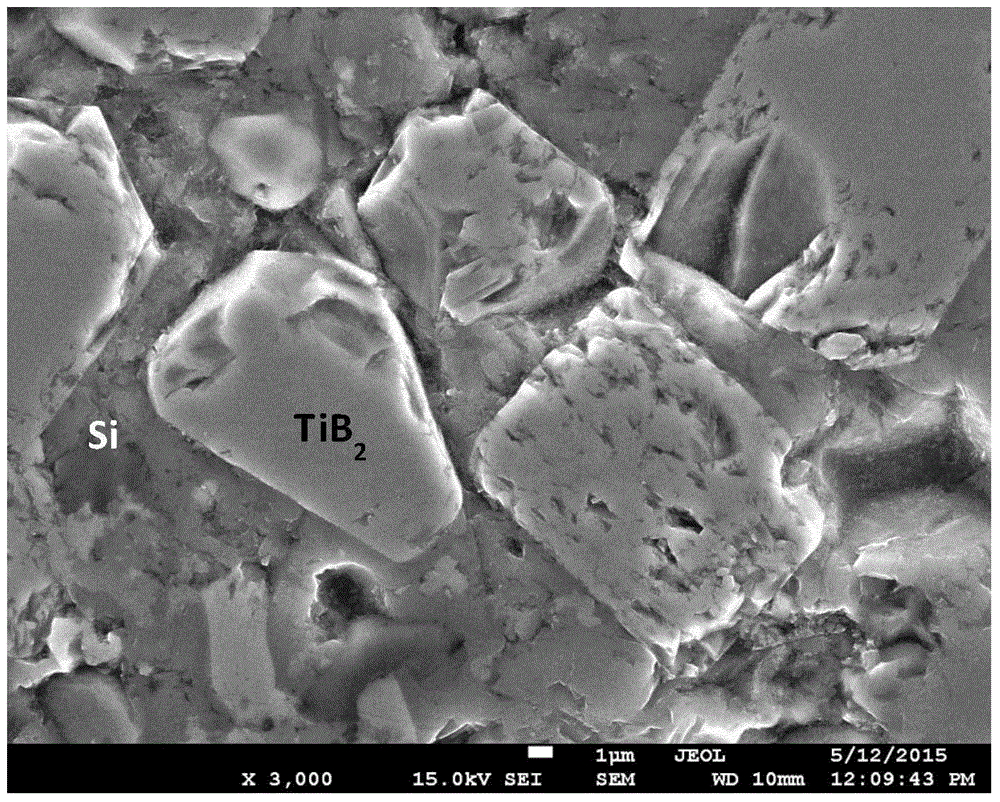

[0029] TiB with particle size 2 powder, molded under a pressure of 50MPa, and then dried at 50°C for 10h to obtain TiB 2 Biscuit;

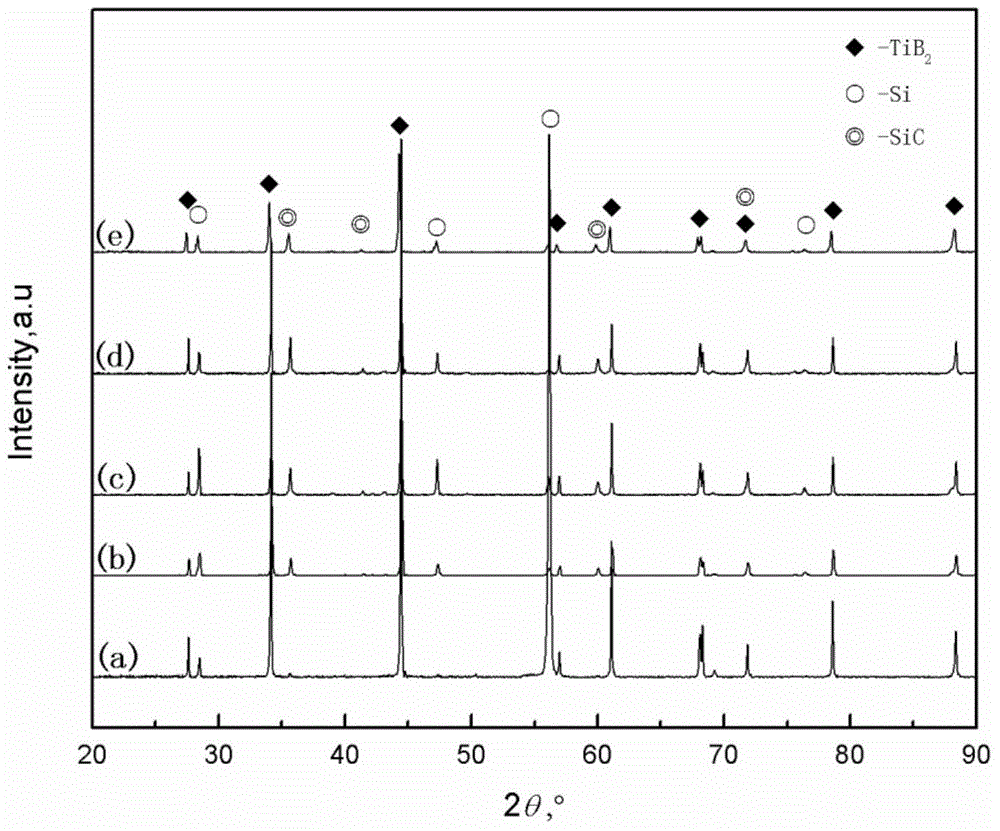

[0030] Place silicon particles on the upper surface of the green body and place it in a vacuum heating furnace. Under the condition of vacuum degree ≤ 100Pa, the temperature is raised to 1450°C at a rate of 10°C / min, and then kept for 60min to obtain a dense titanium diboride-based ceramic composite material. ; its phase composition is TiB 2 and Si.

[0031] After testing, the Vickers hardness of the titanium diboride-based ceramic composite material is 11GPa, the flexural strength is 130MPa, and the fracture toughness is 3.7MPa m 1 / 2 , the open porosity is 0.63%, and the bulk density is 3.64g / cm 3 , the relative density is 91.23%.

Embodiment 2

[0033] Phenolic resin solution, TiB particle size 2 Mix the powder and water evenly, among them, the C element in the phenolic resin solution and the TiB 2 The weight ratio of the powder is 1:24, and the weight ratio of C element and water in the phenolic resin solution is 1:8, and then dried at 110-120°C for 12 hours to remove moisture and make TiB 2 mixed powder;

[0034] TiB 2 The mixed powder is sieved, and the particles with a particle size of 24-60 mesh are selected and put into a mold, molded under a pressure of 100MPa, and then dried at 150°C for 10h to obtain TiB 2 base blank;

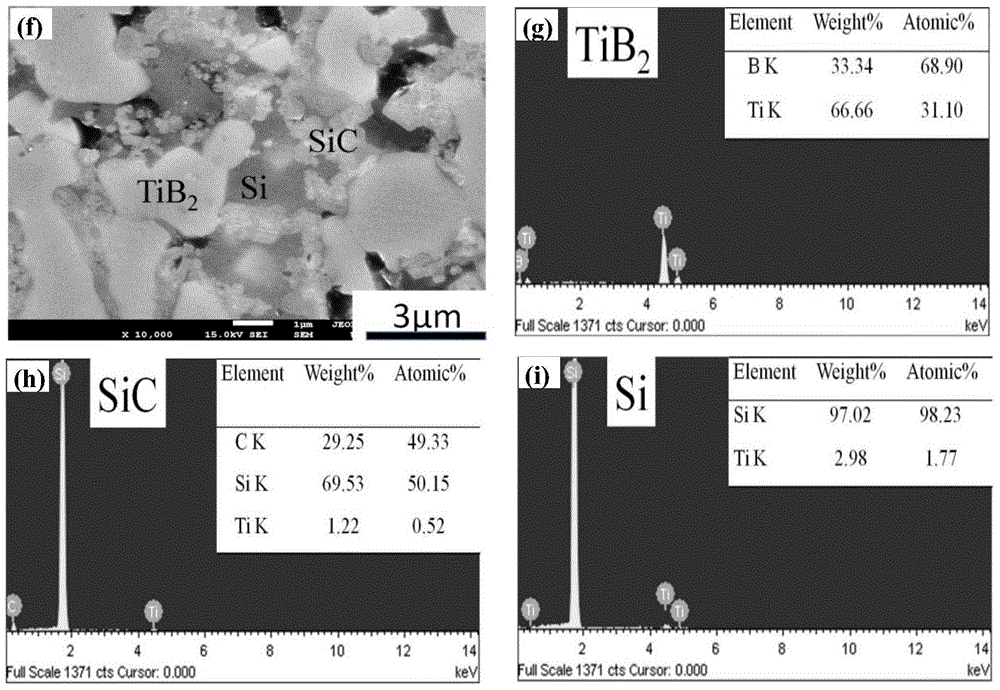

[0035] Place silicon particles on the upper surface of the green body and place it in a vacuum heating furnace. Under the condition of vacuum degree ≤ 100Pa, the temperature is raised to 1500°C at a rate of 3°C / min, and then kept for 60min to obtain a dense titanium diboride-based ceramic composite. material; its phase composition is TiB 2 , SiC and Si;

[0036] After testing, the Vickers...

Embodiment 3

[0038] Water-soluble phenolic resin powder, TiB with particle size 2 The powder and water are mixed evenly, and the phenolic resin is dissolved in water, among which, the C element in the phenolic resin powder and TiB 2 The weight ratio of the powder is 1:15.67, and the weight ratio of the C element in the phenolic resin powder to water is 1:16, and then dried at 110-120°C for 10 hours to remove moisture and make TiB 2 mixed powder;

[0039] TiB 2 The mixed powder is sieved, and the particles with a particle size of 24-60 mesh are selected and put into a mold, molded under a pressure of 150MPa, and then dried at 100°C for 12 hours to obtain TiB 2 base blank;

[0040] Place silicon particles on the upper surface of the green body and place it in a vacuum heating furnace. Under the condition of vacuum degree ≤ 100Pa, the temperature is raised to 1550°C at a rate of 5°C / min, and then kept for 50min to obtain dense titanium diboride-based ceramics. Composite material; its phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com