Preparation method of high-purity vildagliptin

A high-purity, crude product technology, applied in the direction of organic chemistry, can solve the problems of low acetylation yield, difficulty in removing by-products, and small residual amount of 3-amino-1-adamantanol, so as to reduce the content and reduce the The effect of impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Synthesis of vildagliptin crude product

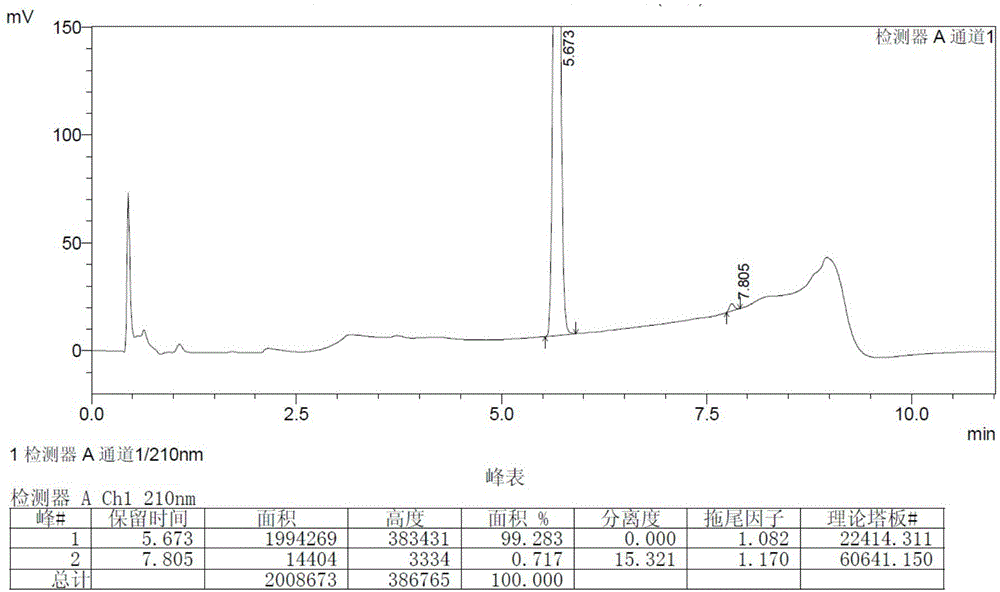

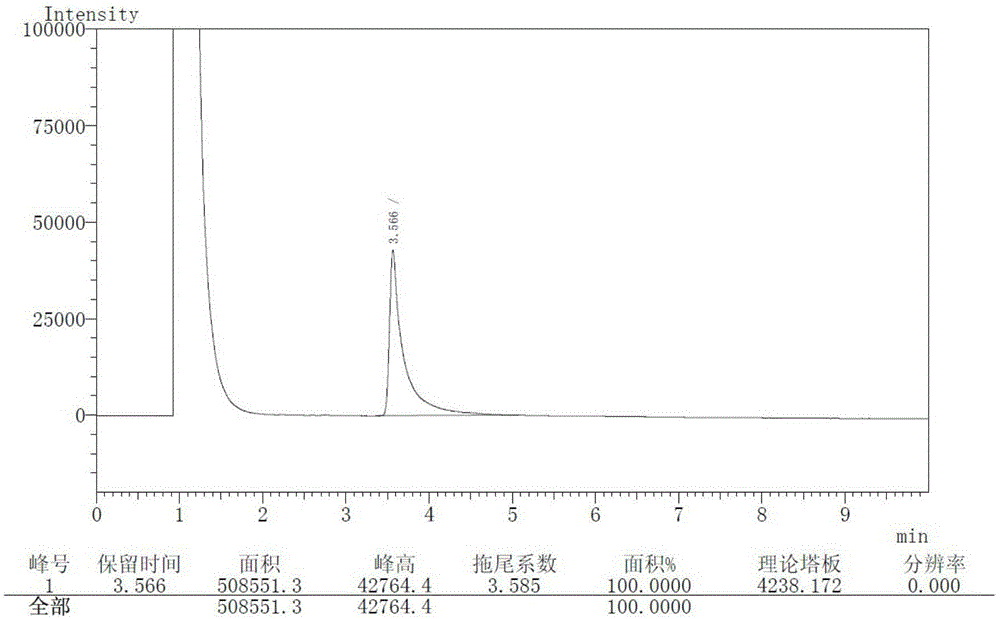

[0036] Add 500ml of tetrahydrofuran and 92g of 3-amino-1-adamantanol into a 1L three-necked flask, stir to dissolve the solid, then add 138g of potassium carbonate and 1.7g of potassium iodide, stir to cool down to 0°C to 5°C, add (2S)- 86.3 g of 1-(2-chloroacetyl)-2-pyrrolidinecarbonitrile. The temperature was controlled and the reaction was stirred for 10 hours, and the oil was obtained after post-treatment. Vildagliptin crude product 114.2g was obtained by crystallization of 2-butanone, with a yield of 75.3%. The HPLC and GC spectra of the crude product are respectively shown in the attached figure 1 And attached image 3 .

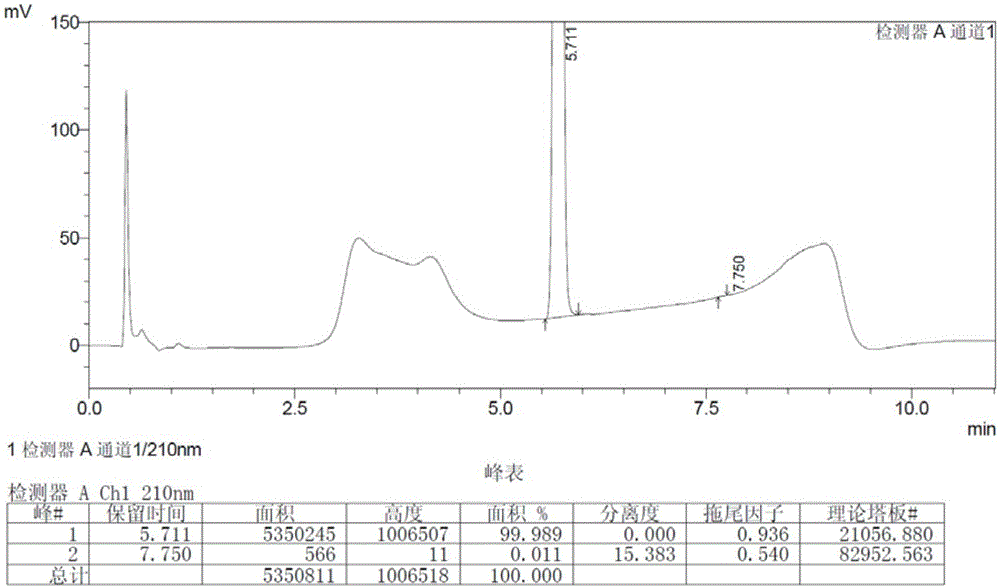

[0037] (2) Crude refined

[0038] Add the crude product (100g) into 2-butanone (1.6L) and isopropanol (0.64L), heat to 60-70°C to dissolve the solid, filter, cool to 0-10°C to crystallize for 6 hours, and filter with suction. Dry under reduced pressure at 50°C to obtain 67.4g of refined product o...

Embodiment 2

[0040] (1) Synthesis of vildagliptin crude product

[0041] Add 1000ml of tetrahydrofuran and 192.3g of 3-amino-1-adamantanol into a 2L three-necked flask, stir to dissolve the solid, then add 276g of potassium carbonate and 3.4g of potassium iodide, stir to cool down to 0°C to 5°C, add (2S) - 172.6 g of 1-(2-chloroacetyl)-2-pyrrolidinecarbonitrile. The reaction was carried out under temperature control and stirring for 10 hours, and after treatment, an oily substance was obtained, and 218.8 g of crude vildagliptin was obtained by crystallization with isopropanol, with a yield of 72.1%.

[0042] (1) Crude refined

[0043] Add the crude product (200g) to 2-butanone (3.4L) and isopropanol (1.3L), heat to 60-70°C to dissolve the solid, filter, cool to 0-10°C to crystallize for 6 hours, and filter with suction. Drying under reduced pressure at 50°C yielded 138.4 g of white crystal refined product with a yield of 69.2%.

Embodiment 3

[0045] (1) Synthesis of vildagliptin crude product

[0046] Add 120ml of dichloromethane and 21g of 3-amino-1-adamantanol into a 500ml three-necked flask, stir to dissolve the solid, then add 33g of anhydrous potassium carbonate and 0.4g of potassium iodide, stir to cool down to 5°C-10°C, add 20.6 g of (2S)-1-(2-chloroacetyl)-2-pyrrolidinecarbonitrile. The reaction was carried out under temperature control and stirring for 12 hours, and post-treatment was carried out to obtain an oily product, which was crystallized with 2-butanone to obtain 25.5 g of crude vildagliptin, with a yield of 70.5%.

[0047] (2) Crude refined

[0048]Add the crude product (20g) to 2-butanone (300ml) and isopropanol (120ml), heat to 60-70°C to dissolve the solid, filter, cool to 0-10°C to crystallize for 6 hours, suction filter, 50°C After drying under reduced pressure, 13.7 g of white crystalline refined product was obtained, with a yield of 68.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com