Antibacterial-plant-pigment-added biodegradable packaging material and preparation method thereof

A biodegradable material and biodegradable technology, applied in the field of biodegradable packaging materials added with antibacterial plant pigments and its preparation, can solve the problems of high production cost and waste of resources, and achieve the effect of low equipment requirements and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

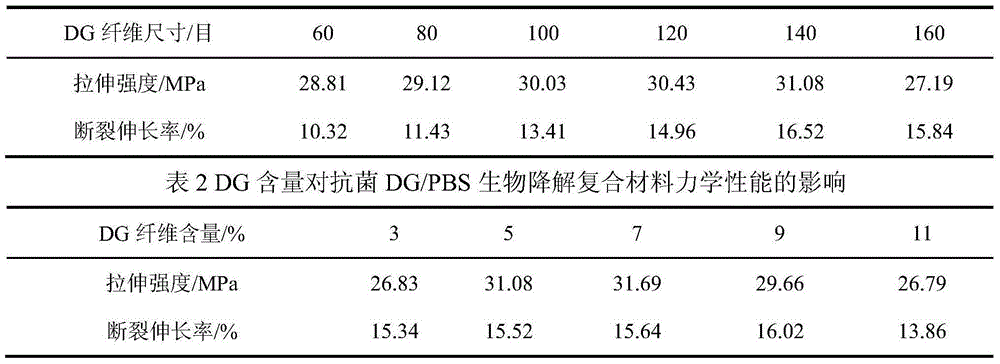

[0033] A preparation method of distiller's grains / PBS biodegradable packaging material added with antibacterial plant-derived pigments, comprising the following steps:

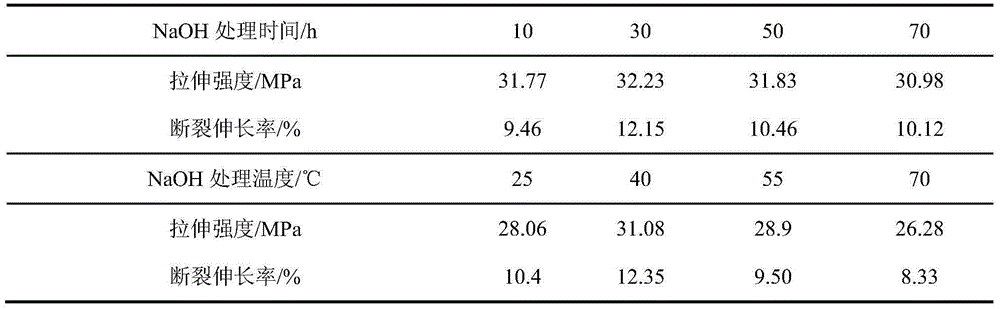

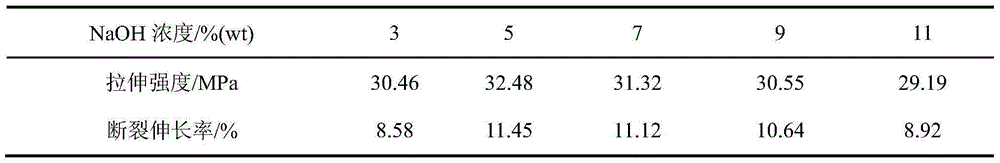

[0034] 1) Using an alkali solution containing 3 parts of 5% NaOH solution and 2 parts of fiber protection additive (sodium sulfide), pretreating 180 μm distiller's grain fibers in a 40°C water bath for 40 minutes to obtain modified distiller's grain fibers;

[0035] 2) Prepare PBS polyester by melting polycondensation method. The specific method is to mix 0.11 parts of diacid (succinic acid), 0.1 part of diol (butanediol), and 10 μL of catalyst (ethylene glycol antimony) under normal pressure at 130 ° C. The dehydration condensation reaction is 5h, and the pressure reduction polymerization reaction is 3h at 200°C.

[0036] The PBS biodegradable material was purified by organic solvent precipitation, and vacuum-dried at 60°C to obtain the PBS biodegradable material. 100 parts of PBS biodegradable material, 1.2...

Embodiment 2

[0040] A preparation method of distiller's grains / PBS biodegradable packaging material added with antibacterial plant-derived pigments, comprising the following steps:

[0041] 1) Using an alkali solution containing 5 parts by mass fraction of 5% NaOH solution and 3 parts of a fiber protection aid (sodium sulfite), pretreating 150 μm distiller's grain fibers in a water bath at 55°C for 50 minutes to obtain modified distiller's grain fibers;

[0042] 2) Prepare PBS polyester by melting polycondensation method. The specific method is to dehydrate 1.1 parts of diacid (succinic acid), 1 part of diol (butylene glycol), and 20 μL of catalyst (stannous octoate) at 150 ° C under normal pressure. Condensation reaction for 6 hours, pressure reduction polymerization reaction at 220°C for 4 hours. The PBS biodegradable material was purified by organic solvent precipitation, and vacuum-dried at 60°C to obtain the PBS biodegradable material. 100 parts of PBS biodegradable material, 1.5 par...

Embodiment 3

[0046] A preparation method of distiller's grains / PBS biodegradable packaging material added with antibacterial plant-derived pigments, comprising the following steps:

[0047] 1) Using an alkali solution containing 7 parts of 3% NaOH solution and 4 parts of fiber protection additive (sodium thiosulfate), pretreat 120 μm distiller's grain fibers in a water bath at 80°C for 40 minutes to obtain modified distiller's grains fiber;

[0048] 2) Prepare PBS polyester by melting polycondensation method. The specific method is to use 3.3 parts of diacid (succinic acid), 3 parts of diol (butylene glycol), 50 μL of catalyst (tin protochloride) at 150 ° C under normal pressure The dehydration condensation reaction is 6h, and the compression polymerization reaction is 4h at 240°C. The PBS biodegradable material was purified by organic solvent precipitation, and vacuum-dried at 60°C to obtain the PBS biodegradable material. 100 parts of PBS biodegradable material, 2 parts of plasticizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com