Liquid metal-gas battery and preparation method thereof

A technology of gas batteries and liquid metals, which is applied in the direction of fuel cells, battery electrodes, fuel cell half-cells and primary battery-type half-cells, etc. Issues such as battery cycle life and safety, to achieve the effect of improving migration and ion transport performance, improving electrochemical performance, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

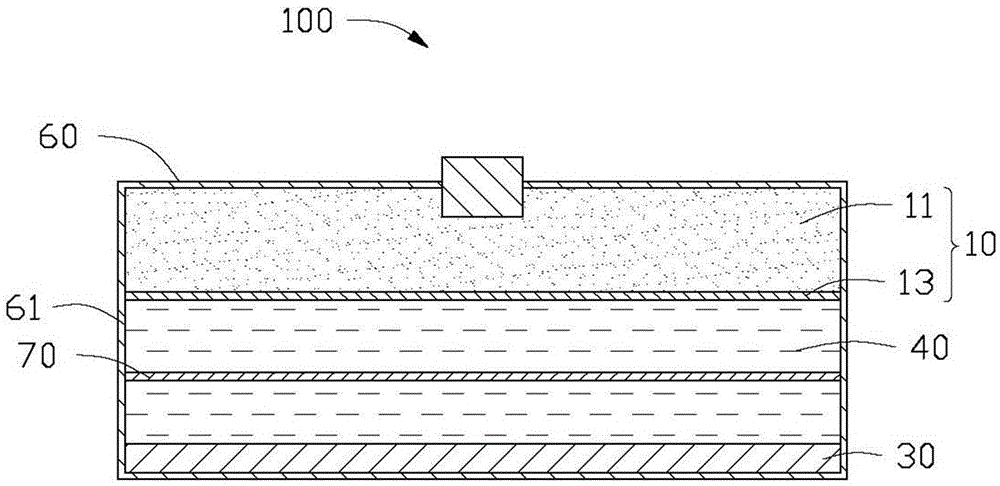

[0016] A preparation method of the liquid metal-gas battery 100, comprising the following steps:

[0017] Step S1 , providing a housing 60 including a cavity 61 .

[0018] Step S2 , placing the negative electrode material, the electrolyte 40 , and the separator 70 in the cavity 61 of the casing 60 in sequence. At this time, the shape of the negative electrode material depends on the temperature of the production environment, and it can be liquid or solid. The negative electrode material is a metal, and the metal can be selected from at least one of lithium, sodium, potassium, rubidium, cesium, magnesium, calcium, aluminum, tin, gallium and indium. The negative electrode material forms the negative electrode 30 . The electrolyte 40 contains ions formed from at least one metal contained in the negative electrode material.

[0019] Step S3 , fixing a positive electrode conductive membrane 13 with a porous structure in the cavity 61 on the side of the electrolyte 40 away from t...

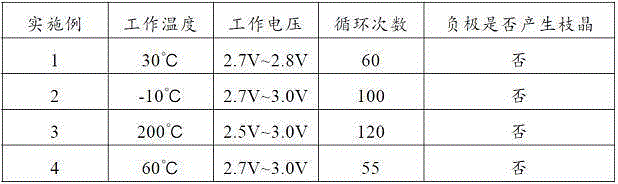

Embodiment 1

[0024] Preparation of electrolyte solution 40: cesium trifluoromethanesulfonate (CsSO 3 CF 3 ) into ethylene glycol dimethyl ether (DME) to obtain electrolyte solution 40 , wherein the concentration of cesium trifluoromethanesulfonate is 1.0 mol / L.

[0025] Preparation of the positive electrode conductive membrane 13 : the conductive carbon black (Super-P) was mixed with the adhesive, stirred and pressed at room temperature to obtain the positive electrode conductive membrane 13 with a porous structure.

[0026] Assembly of the liquid metal-gas battery 100: put cesium metal (melting point 28.4°C) as the negative electrode material in the cavity 61 of the housing 60, then fill the cavity 61 with the prepared electrolyte solution 40, and then place the prepared The positive electrode conductive membrane 13 is fixed in the cavity 61 and located at the end of the electrolyte 40 away from the negative electrode material, filled with oxygen as the positive electrode active material...

Embodiment 2

[0028] Preparation of electrolyte solution 40: cesium trifluoromethanesulfonate (CsSO 3 CF 3 ) into ethylene glycol dimethyl ether (DME) to obtain electrolyte solution 40 , wherein the concentration of cesium trifluoromethanesulfonate is 1.0 mol / L.

[0029] Preparation of the positive electrode conductive membrane 13: mixing the carbon nanotubes and the adhesive, stirring and pressing at room temperature to obtain the positive electrode conductive membrane 13 with a porous structure.

[0030] Assembly of the liquid metal-gas battery 100: the alloy of metal sodium and cesium (melting point is -30°C) is placed in the cavity 61 of the casing 60 as the negative electrode material, and then the prepared electrolyte 40 is filled in the cavity 61 , and then fix the prepared positive electrode conductive membrane 13 in the cavity 61 at the end of the electrolyte 40 away from the negative electrode material, fill in chlorine gas as the positive electrode active material 11, and then p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com