Preparation method for nanofiber porous scaffold having compression elasticity in wet state

A nanofiber and compressive elasticity technology is applied in the field of preparation of three-dimensional porous scaffolds, which can solve the problems of poor mechanical properties of scaffolds, poor mechanical properties of three-dimensional scaffolds, and difficulty in application, and achieve the effects of high compressive elasticity and excellent water absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

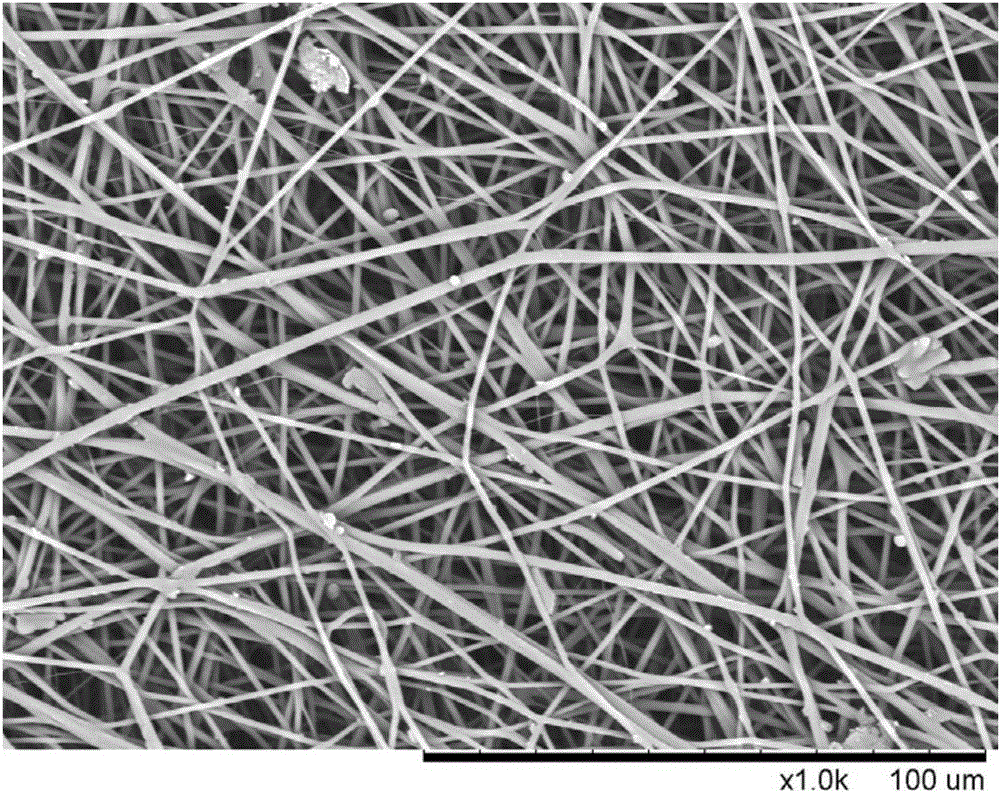

[0027] Gelatin and polylactic acid (mass ratio 1:5) were dissolved in hexafluoroisopropanol, with a total mass fraction of 11%. Inhale the solution into the syringe, control the advance rate of the micro-injection pump to 5mL / h, connect a 15KV high-voltage power supply to the syringe needle, and receive it with aluminum foil at a receiving distance of 15cm. Gelatin / PLA nanofiber membranes were obtained by electrospinning.

Embodiment 2

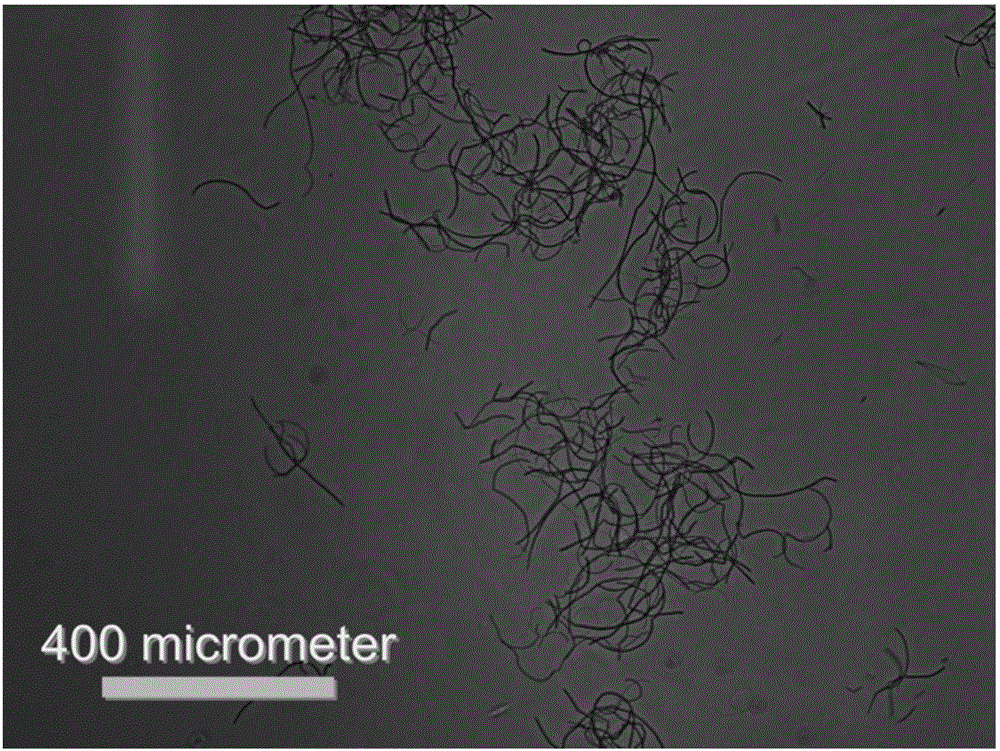

[0029] Gelatin and polylactic acid (mass ratio 1:5) were dissolved in hexafluoroisopropanol, with a total mass fraction of 11%. Inhale the solution into the syringe, control the advance rate of the micro-injection pump to 5mL / h, connect a 15KV high-voltage power supply to the syringe needle, and receive it with aluminum foil at a receiving distance of 15cm. Gelatin / PLA nanofiber membranes were obtained by electrospinning. Cut the nanofibrous membrane into a sheet with a size of about 0.5×0.5 cm with scissors. Then weigh 1 g of the nanofiber membrane and add it to a beaker containing 100 mL of tert-butanol, and use a high-speed pulverizer to pulverize the nanofiber membrane into a uniform short fiber solution.

Embodiment 3

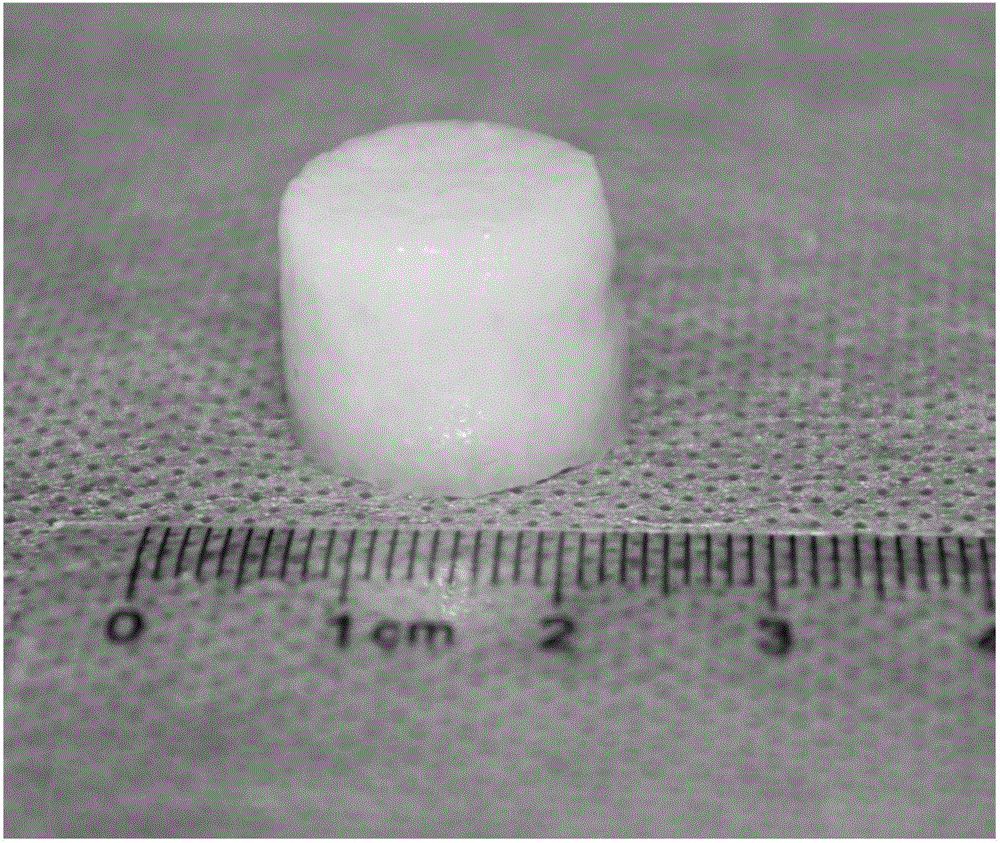

[0031] Gelatin and polylactic acid (mass ratio 1:5) were dissolved in hexafluoroisopropanol, with a total mass fraction of 11%. Inhale the solution into the syringe, control the advance rate of the micro-injection pump to 5mL / h, connect a 15KV high-voltage power supply to the syringe needle, and receive it with aluminum foil at a receiving distance of 15cm. Gelatin / PLA nanofiber membranes were obtained by electrospinning. Cut the nanofibrous membrane into a sheet with a size of about 0.5×0.5 cm with scissors. Then weigh 1 g of the nanofiber membrane and add it to a beaker containing 100 mL of tert-butanol, and use a high-speed pulverizer to pulverize the nanofiber membrane into a uniform short fiber solution. Then, add the short fiber solution into the mold, put it in a refrigerator at -80° C., and freeze it for 1 hour. Finally, put it into a vacuum freeze dryer and dry it for 24 hours to obtain a three-dimensional scaffold. Put the scaffold into a mixed solution of glutaral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com