A nickel-molybdenum carbide composite catalyst for dry reforming of methane to synthesis gas

A technology for dry reforming of methane and composite catalyst, which is applied in the fields of physical/chemical process catalyst, inorganic chemistry, bulk chemical production, etc., can solve the problems of complicated operation, catalyst deactivation, long carbonization time, etc. The effect of increasing the number of catalytic active centers and reducing the thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0027] Weigh 25.79 grams of Al(NO 3 ) 3 .9H 2 O and 10.32 g CO(NH 2 ) 2 , add 20 ml of deionized water and mix to form solution #1, and place it in a constant temperature water bath at 80°C under magnetic stirring. Weigh 2.94 g of starch and add 5 mL of deionized water to form solution #2. Weigh 4.25 g (NH 4 ) 6 Mo 7 o 24 .4H 2 O and 1.08 g of citric acid were added to 10 mL of deionized water to form solution #3. Slowly drop #2 into solution #1 to form a homogeneous mixture, then drop into solution #3 and stir for 2.5h to form a gel. Dry at 105°C for 12h, and bake at 550°C for 5h; then in 50ml / min of CH 4 / CO 2 =1 in the mixed gas at 5°C / min to 800°C for carbonization to obtain the CDUT-M5A catalyst, the nitrogen adsorption / desorption test results show that its specific surface area is 32.6m 2 / g. The weight composition of the catalyst is as follows: the content of molybdenum carbide is 12.4%, and the content of aluminum oxide is 87.6%.

[0028] The catalyst wa...

Embodiment 1

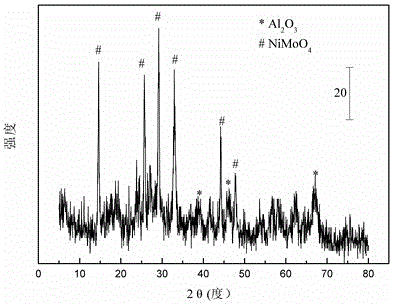

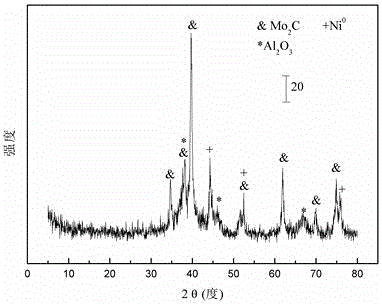

[0030] Weigh 22.56 grams of Al(NO 3 ) 3 .9H 2 O and 9.03 g CO(NH 2 ) 2 , add 20 milliliters of deionized water and mix to form solution #1, place it in a constant temperature water bath at 80°C under magnetic stirring; weigh 2.57 grams of starch, add 5 milliliters of deionized water to form solution #2; weigh 2.81 grams of Ni ( NO 3 ).6H 2 O, 2.23 g (NH 4 ) 6 Mo 7 o 24 .4H 2 0 and 3.41 grams of citric acid, add 10 milliliters of deionized water to form solution #3; #2 is slowly dropped into solution #1 to form a uniform mixture, and solution #3 is added dropwise, and stirred for 2.5h to form a gel; Dry at 105°C for 12h, and bake at 550°C for 5h to obtain the oxide precursor, whose typical nickel-molybdenum oxide structure is as attached figure 1 shown; then, at 50ml / min of CH 4 / CO 2 =1 in the mixed gas at 5°C / min to 800°C for carbonization to obtain CDUT-NM3A catalyst, the typical Ni-Mo 2 C / Al 2 o 3 Composite figure 2 shown. After nitrogen adsorption / desorp...

Embodiment 2

[0033] Weigh 21.63 grams of Al(NO 3 ) 3 .9H 2 O and 8.66 g CO(NH 2 ) 2 , add 20 milliliters of deionized water and mix to form solution #1, place it in a constant temperature water bath at 80°C under magnetic stirring; weigh 2.37 grams of starch, add 5 milliliters of deionized water to form solution #2; weigh 2.52 grams of Ni ( NO 3 ).6H 2 O, 3.56 g (NH 4 ) 6 Mo 7 o 24 .4H 2 0 and 3.63 grams of citric acid, add 10 milliliters of deionized water to form solution #3; #2 is slowly dropped into solution #1 to form a uniform mixture, and solution #3 is added dropwise, and stirred for 2.5h to form a gel; Dry at 105°C for 12h, and bake at 550°C for 5h to obtain the oxide precursor, whose typical nickel-molybdenum oxide structure is as attached figure 1 shown; then, at 50ml / min of CH 4 / CO 2 =1 in the mixed gas at 5°C / min to 800°C for carbonization to obtain CDUT-NM5A catalyst, its typical Ni-Mo 2 C / Al 2 o 3 Composite figure 2 shown. After nitrogen adsorption / desorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com