Advanced treatment technology of high-salt-content degradation-resistant oil extraction sewage

A technology for advanced treatment and oily sewage, applied in mining wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low sludge settlement efficiency, low sludge settlement efficiency, and biodegradation salinity issues such as significant impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

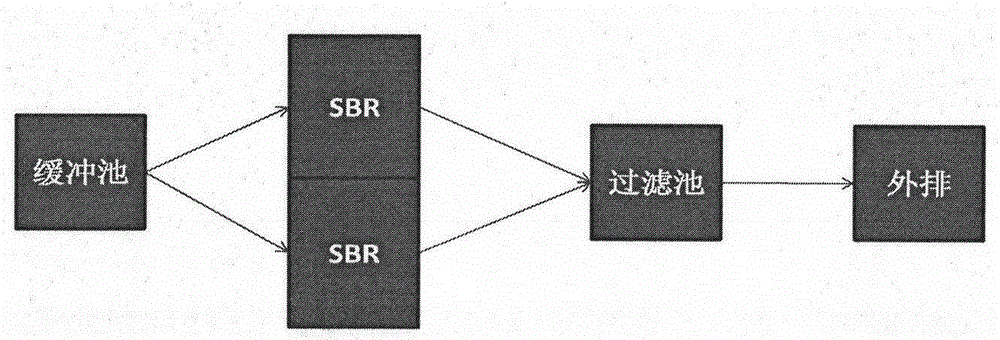

[0055] Example 1: Advanced treatment of high-salt oil production wastewater in an oil field:

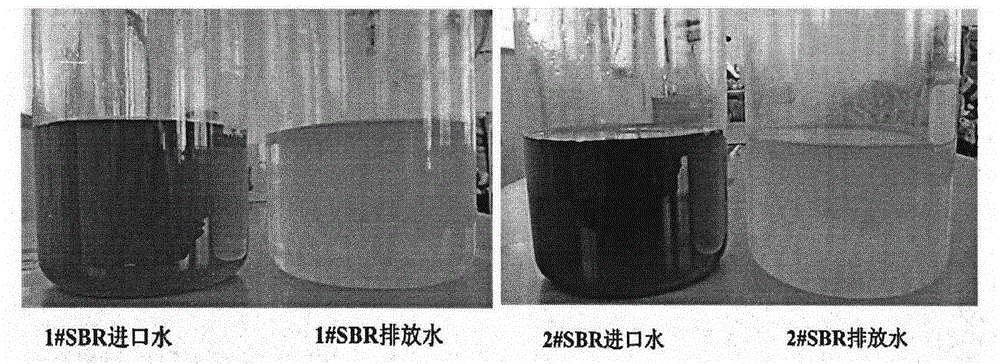

[0056] Add highly active COD-degrading strains-W2, W5, 2D1 and 3D1 in the aerobic aerated activated sludge tank to obtain a high-concentration bacterial solution of 108CFU / ml, and then add it to 1# and 2#SBR (sequencingbatchreactor) for treatment Pool, and add carbon source sodium acetate, nitrogen source and phosphorus source ammonium dihydrogen phosphate, C / N ratio 5:1, sodium acetate final concentration 100ppm, in order to improve the treatment effect of 1# and 2#SBR. From 2013 / 6 / 1 to 2013 / 6 / 10, a total of 4.8 tons of COD-degrading bacteria solution was added to 1# and 2# SBR pools four times, 0.6 tons were added each time, and once every three days ; 1# and 2# SBR degradation COD results show that when the inlet water sample COD≤350mg / L, the outlet water sample COD is lower than 60mg / L; the inlet water sample COD range is 350mg / L-400mg / L, the outlet water sample The COD is lower...

Embodiment 2

[0058] After the high-concentration COD (more than 350mg / l) oil production wastewater is treated by the SBR tank, the COD of the outlet discharge is about 100mg / l, which has not reached the national first-level discharge standard. Take the external drainage with a COD of about 100mg / l and pour it into a shaker flask, inoculate 1% compound salt-tolerant Bacillus brevus degrading flora, and treat it at 140r / min for 24 hours, and the COD can be reduced to 57.92mg / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com