High-magnetic-conductibility low-loss soft-magnetic ferrite material and preparation method therefor

A technology of soft magnetic ferrite and high magnetic permeability, applied in the field of soft magnetic ferrite, can solve the problems of low magnetic core loss and unsatisfactory magnetic core loss, etc., to achieve reduced magnetic core loss, high magnetic permeability, and improved resistivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

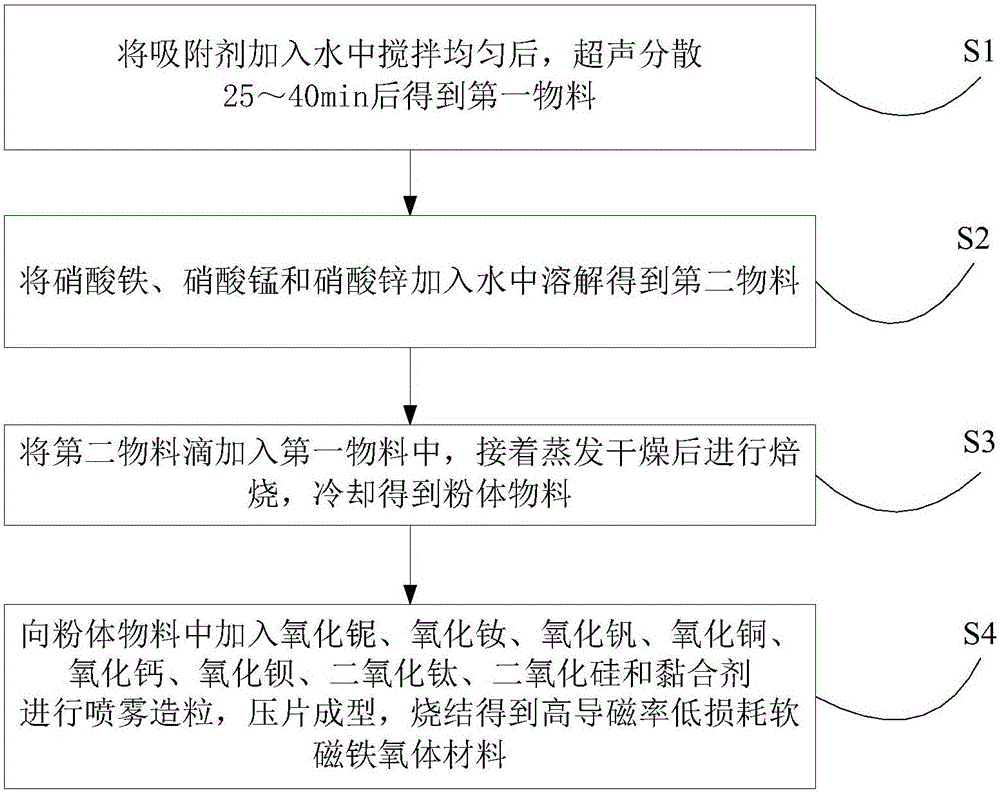

[0028] refer to figure 1 , the preparation method of a kind of high magnetic permeability and low loss soft ferrite material that the present invention proposes, comprises the following steps:

[0029] S1. After adding the adsorbent into water and stirring evenly, ultrasonically disperse for 25-40 minutes to obtain the first material;

[0030] S2, adding ferric nitrate, manganese nitrate and zinc nitrate into water to dissolve to obtain the second material;

[0031] S3, adding the second material dropwise to the first material, followed by evaporating and drying, roasting, and cooling to obtain a powder material;

[0032] S4. Add niobium oxide, neodymium oxide, vanadium oxide, copper oxide, calcium oxide, barium oxide, titanium dioxide, silicon dioxide and binder to the powder material for spray granulation, tablet molding, and sintering to obtain high magnetic permeability and low permeability Lossy soft ferrite material.

Embodiment 1

[0035]The present invention proposes a soft magnetic ferrite material with high magnetic permeability and low loss. Its raw materials include main materials and auxiliary materials, wherein the main materials include: 52.5 mol% of iron nitrate, 35.5 mol% of manganese nitrate, and 12 mol% of zinc nitrate; Based on the total weight of the main ingredients, the auxiliary materials include: niobium oxide 700ppm, neodymium oxide 100ppm, vanadium oxide 300ppm, copper oxide 200ppm, calcium oxide 800ppm, barium oxide 20ppm, titanium dioxide 100ppm, silicon dioxide 10ppm, polycarbonate 2500ppm, adsorption agent 8 x 10 6 ppm.

[0036] The preparation method of the above-mentioned high magnetic permeability and low loss soft ferrite material also proposed by the present invention comprises the following steps:

[0037] S1. After adding the adsorbent into water and stirring evenly, the first material was obtained after ultrasonic dispersion for 30 minutes;

[0038] S2, adding ferric nit...

Embodiment 2

[0042] The present invention proposes a soft magnetic ferrite material with high magnetic permeability and low loss. Its raw materials include main materials and auxiliary materials, wherein the main materials include: iron nitrate 53mol%, manganese nitrate 34mol%, zinc nitrate 13mol%; Based on the total weight of materials, the auxiliary materials include: niobium oxide 400ppm, neodymium oxide 200ppm, vanadium oxide 220ppm, copper oxide 270ppm, calcium oxide 400ppm, barium oxide 60ppm, titanium dioxide 50ppm, silicon dioxide 60ppm, SBR latex 2200ppm, adsorbent 8.8× 10 6 ppm; of which calcium oxide, barium oxide, titanium dioxide and silicon dioxide are 700 mesh.

[0043] The preparation method of the above-mentioned high magnetic permeability and low loss soft ferrite material also proposed by the present invention comprises the following steps:

[0044] S1. After adding the adsorbent to water and stirring evenly, the first material was obtained after ultrasonic dispersion f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com