Low dielectric constant polyamide aerogel thermal insulation material and preparation method thereof

A low-dielectric-constant, polyamide gel technology is applied in the field of low-dielectric-constant polyamide aerogel insulation materials and their preparation, and can solve the problems of low-dielectric-constant, low-dielectric-constant, serious dust pollution, etc. , to achieve the effect of reducing the dielectric constant, good barrier effect and good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

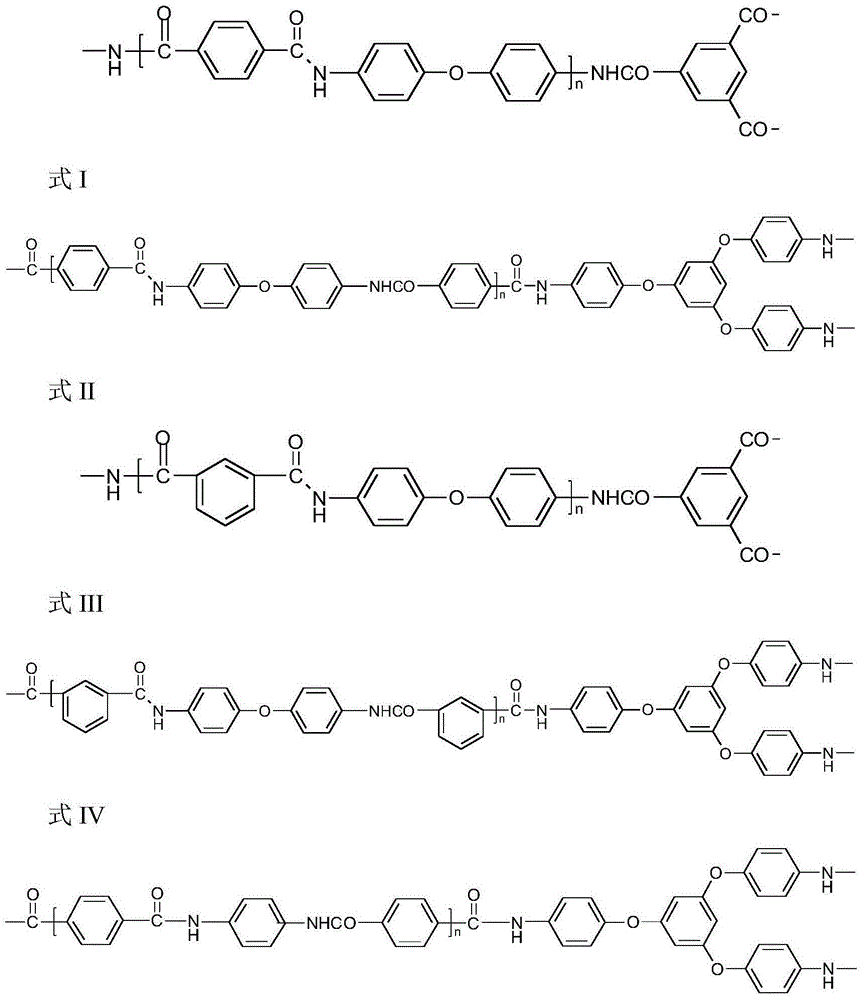

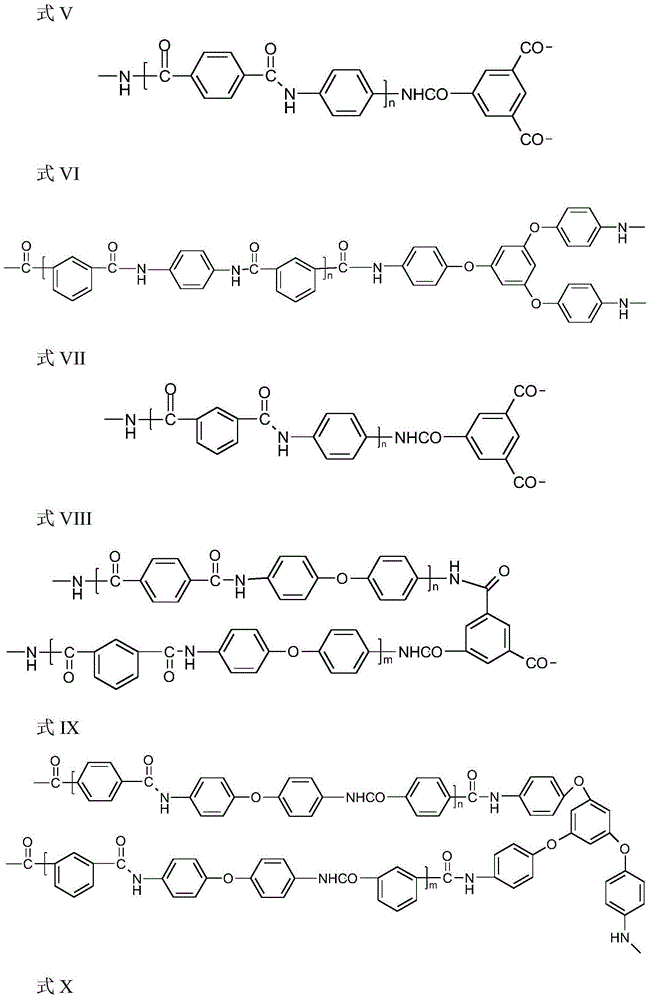

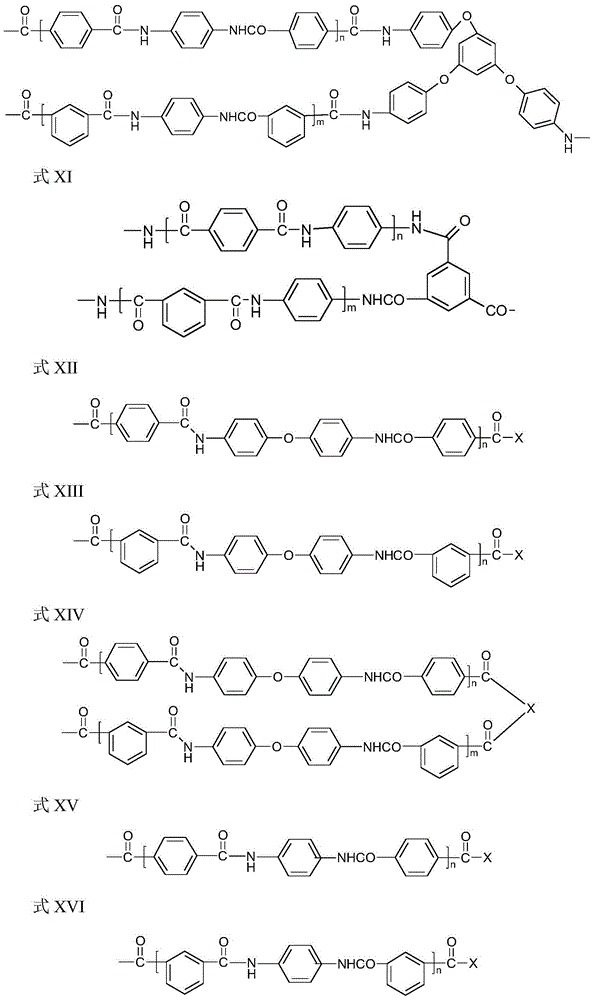

Method used

Image

Examples

Embodiment 1

[0032] In the first step, 4,4'-diaminodiphenyl ether (ODA) was dissolved in anhydrous N-methylpyrrolidone (NMP) under nitrogen protection, and terephthaloyl chloride (TPC) was added to the above solution , stirring under a nitrogen atmosphere to form a clear and transparent polyamide sol, wherein the molar ratio of TPC to ODA is 0.95:1.00;

[0033] In the second step, the cross-linking agent 1,3,5-benzenetricarboxylic acid chloride (BTC) is added to the sol obtained in the first step to obtain a cross-linked polyamide sol, which is stirred and reacted for 20 minutes under a nitrogen atmosphere, and the sol is poured Put it into the mold and let it stand for 30 minutes to treat the polyamide gel obtained by its gel. The obtained polyamide gel was aged in anhydrous NMP for 24 hours and then subjected to solvent replacement to obtain a polyamide gel after solvent replacement. Wherein the molar ratio of BTC to ODA is 0.022:1.000, and the solvent is replaced with a mixed solution ...

Embodiment 2

[0036] In the first step, 4,4'-diaminodiphenyl ether (ODA) was dissolved in anhydrous N,N-dimethylformamide (DMF) under nitrogen protection, and terephthaloyl chloride (TPC) was added into the above solution, stirred under a nitrogen atmosphere to form a clear and transparent polyamide sol, wherein the molar ratio of TPC to ODA is 0.95:1.00;

[0037] In the second step, the cross-linking agent 1,3,5-benzenetricarboxylic acid chloride (BTC) is added to the sol obtained in the first step to obtain a cross-linked polyamide sol, which is stirred and reacted for 20 minutes under a nitrogen atmosphere, and the sol is poured Put it into the mold and let it stand for 30 minutes to treat the polyamide gel obtained by its gel. The obtained polyamide gel was aged in anhydrous DMF for 24 hours and then subjected to solvent replacement to obtain a polyamide gel after solvent replacement. Wherein the molar ratio of BTC to ODA is 0.022:1.000, and the solvent is replaced with a mixed solutio...

Embodiment 3

[0040] In the first step, 4,4'-diaminodiphenyl ether (ODA) was dissolved in anhydrous N,N-dimethylacetamide (DMAc) under nitrogen protection, and terephthaloyl chloride (TPC) was added into the above solution, stirred under a nitrogen atmosphere to form a clear and transparent polyamide sol, wherein the molar ratio of TPC to ODA is 0.95:1.00;

[0041] In the second step, the cross-linking agent 1,3,5-benzenetricarboxylic acid chloride (BTC) is added to the sol obtained in the first step to obtain a cross-linked polyamide sol, which is stirred and reacted for 20 minutes under a nitrogen atmosphere, and the sol is poured Put it into the mold and let it stand for 30 minutes to treat the polyamide gel obtained by its gel. The obtained polyamide gel was aged in anhydrous DMAc for 24 hours and then subjected to solvent replacement to obtain a solvent-substituted polyamide gel. Wherein the molar ratio of BTC to ODA is 0.022:1.000, and the solvent is replaced with a mixed solution of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com