Flame-retardant, acid-proof, alkali-proof and anti-bacterial lubricating oil for mechanical bearing

A technology of acid and alkali resistance and lubricating oil, which is applied in the direction of lubricating compositions, petroleum industry, additives, etc., can solve the problem of single function of lubricating oil, and achieve the effect of low cost of use, good degradability, strong inhibition and killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

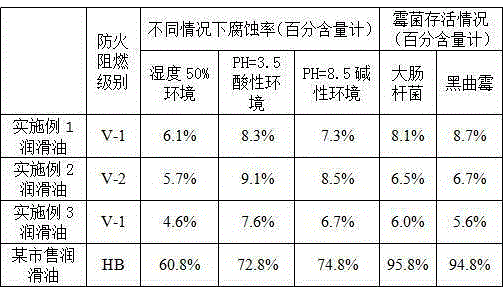

Examples

Embodiment 1

[0040] The flame retardant, acid and alkali resistant and antibacterial lubricating oil for mechanical bearings in this embodiment consists of the following components in parts by mass: 580 parts of base oil, 60 parts of glycerol monostearate, 56 parts of epoxy soybean oil, 60 parts of ketone diisocyanate, 56 parts of isobutyl triethoxysilane, 60 parts of sodium molybdate, 56 parts of polyoxyethylene oleate, 62 parts of dioctyl phthalate, 56 parts of neoprene, 60 parts of pentaerythritol diacid, 56 parts of white oil, 60 parts of zinc stearate, 56 parts of phytate, 60 parts of isothiazolinone, 56 parts of sodium diacetate, 60 parts of methylisothiazolinone, powder 56 parts of coal ash, 60 parts of alumina, 56 parts of dibutyltin dilaurate, 60 parts of tetrabutyl titanate, 56 parts of naphthenic acid, 60 parts of dipropylene glycol methyl ether, 56 parts of cobalt aluminate powder, 60 parts of talc powder share.

[0041] The steps of the method for preparing the flame-retardan...

Embodiment 2

[0046] The flame retardant, acid and alkali resistant and antibacterial lubricating oil for mechanical bearings in this embodiment consists of the following components in parts by mass: 600 parts of base oil, 62 parts of glycerol monostearate, 58 parts of epoxy soybean oil, isofor 62 parts of ketone diisocyanate, 58 parts of isobutyl triethoxysilane, 62 parts of sodium molybdate, 58 parts of polyoxyethylene oleate, 64 parts of dioctyl phthalate, 58 parts of neoprene, 62 parts of pentaerythritol diacid, 58 parts of white oil, 62 parts of zinc stearate, 58 parts of phytate, 62 parts of isothiazolinone, 58 parts of sodium diacetate, 62 parts of methylisothiazolinone, powder 58 parts of coal ash, 62 parts of aluminum oxide, 58 parts of dibutyltin dilaurate, 62 parts of tetrabutyl titanate, 58 parts of naphthenic acid, 62 parts of dipropylene glycol methyl ether, 58 parts of cobalt aluminate powder, 62 parts of talc powder share.

[0047] The steps of the method for preparing the ...

Embodiment 3

[0052] The flame retardant, acid and alkali resistant and antibacterial lubricating oil for mechanical bearings in this embodiment consists of the following components in parts by mass: 620 parts of base oil, 64 parts of glycerol monostearate, 60 parts of epoxy soybean oil, 64 parts of ketone diisocyanate, 60 parts of isobutyl triethoxysilane, 64 parts of sodium molybdate, 60 parts of polyoxyethylene oleate, 66 parts of dioctyl phthalate, 60 parts of neoprene rubber, 64 parts of pentaerythritol diacid, 60 parts of white oil, 64 parts of zinc stearate, 60 parts of phytate, 64 parts of isothiazolinone, 60 parts of sodium diacetate, 64 parts of methylisothiazolinone, powder 60 parts of coal ash, 64 parts of alumina, 60 parts of dibutyltin dilaurate, 64 parts of tetrabutyl titanate, 60 parts of naphthenic acid, 64 parts of dipropylene glycol methyl ether, 60 parts of cobalt aluminate powder, 64 parts of talcum powder share.

[0053] The steps of the method for preparing the flame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com