Preparation method of three-dimensional graphene/tungsten-based nanosheet/magnesium doped zinc oxide layer-by-layer assembly structure

A layer-by-layer assembly, graphene technology, applied in the field of photocatalytic materials, to achieve the effect of less environmental pollution, preventing agglomeration and curling, and improving the enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

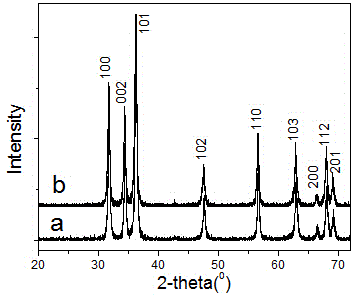

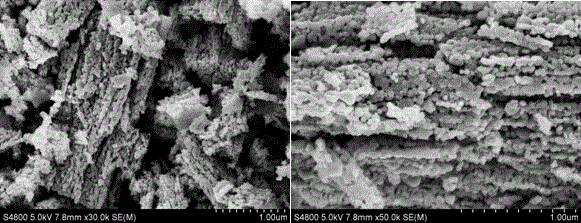

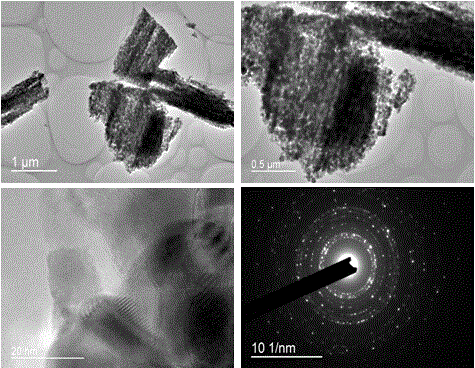

Image

Examples

Embodiment 1

[0032] (1) Add 1g of commercial tungsten oxide powder and 0.1g of cetyltrimethylammonium bromide into 500mL of deionized water, ultrasonically disperse for 30min and then stir for 20min to obtain a tungsten oxide dispersion;

[0033](2) Under ultrasonic vibration, use a high-speed mechanical shear with a speed of 1000r / min to shear the tungsten oxide dispersion in the above step (1) for 1 hour, centrifuge with a speed of 4000r / min, and then stir and ultrasonically disperse 1h, obtain tungsten oxide nanosheet solution;

[0034] (3) Add 10 mL of graphene oxide solution with a concentration of 1 g / L into 50 mL of deionized water and ultrasonically disperse for 20 minutes to obtain a graphene dispersion;

[0035] (4) Add 0.2 g of polyacrylic acid to the graphene oxide dispersion obtained in (3) above, and ultrasonically disperse for 30 minutes to obtain a graphene oxide dispersion;

[0036] (5) Slowly add 2 mL of the tungsten oxide nanosheet solution obtained in the above step (2...

Embodiment 2

[0042] (1) Add 5g of commercial tungsten sulfide powder and 0.5g of cetyltrimethylammonium bromide into 800mL of deionized water, ultrasonically disperse for 40min and then stir for 40min to obtain a tungsten sulfide dispersion;

[0043] (2) Under ultrasonic vibration, use a high-speed mechanical shear with a speed of 7000r / min to shear the tungsten sulfide dispersion in the above step (1) for 3 hours, centrifuge with a speed of 8000r / min and then stir for ultrasonic dispersion 3h, obtain the tungsten sulfide nanosheet solution;

[0044] (3) Add 15 mL of reduced graphene oxide solution with a concentration of 1.2 g / L into 70 mL of deionized water for ultrasonic dispersion for 40 min to obtain a graphene dispersion;

[0045] (4) Add 0.3 g of sodium polyacrylate to the reduced graphene oxide dispersion obtained in (3) above, and ultrasonically disperse for 20 minutes to obtain a graphene dispersion;

[0046] (5) Slowly add 5 mL of the tungsten sulfide nanosheet solution obtaine...

Embodiment 3

[0051] (1) Add 8g of commercial tungsten sulfide powder and 0.8g of cetyltrimethylammonium bromide into 1000mL of deionized water, ultrasonically disperse for 30min and then stir for 30min to obtain a tungsten sulfide dispersion;

[0052] (2) Under ultrasonic oscillation, use a high-speed mechanical shear with a speed of 5000r / min to shear the tungsten sulfide dispersion in the above step (1) for 2 hours, centrifuge with a speed of 5000r / min, and then stir and ultrasonically disperse 2h, obtain the tungsten sulfide nanosheet solution;

[0053] (3) Add 10 mL of graphene solution with a concentration of 0.8 g / L into 50 mL of deionized water and ultrasonically disperse for 20 minutes to obtain a graphene dispersion;

[0054] (4) Add 0.2 g of sodium polyacrylate to the graphene dispersion obtained in (3) above, and ultrasonically disperse for 40 minutes to obtain a graphene dispersion;

[0055] (5) Under stirring and ultrasonic oscillation, slowly add 4 mL of the tungsten sulfide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com