Process for reducing SO2 emission concentration of sulfur recovery device

A sulfur recovery and SO2 technology, applied in the direction of sulfur preparation/purification, etc., can solve the problems of increasing pipeline and equipment size, increasing process gas volume, pipeline and equipment corrosion, etc., so as to avoid the increase of pipeline and equipment size and reduce gas consumption. Low gas volume and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

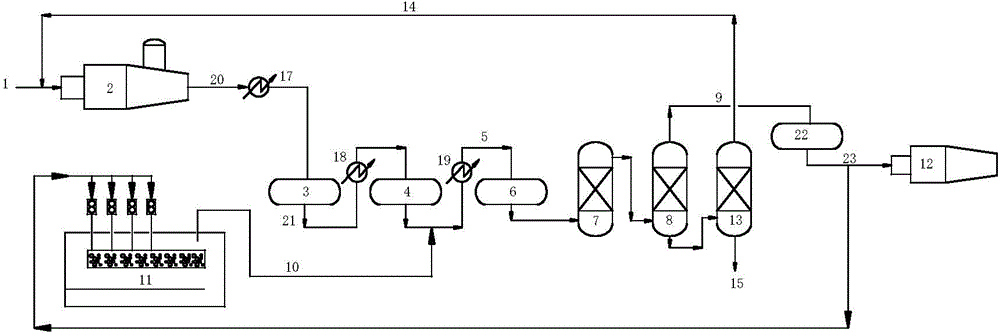

[0057] process such as figure 1shown. The process includes thermal reaction section, catalytic reaction section and tail gas purification treatment section.

[0058] In the thermal reaction section, the acid gas 1 containing 94 (v / v)% hydrogen sulfide is partially burned in the reactor 2 and converted to sulfur dioxide. At a high temperature of 1260°C, hydrogen sulfide and sulfur dioxide undergo a Claus reaction to generate elemental sulfur and reactor tail gas. 20. After being cooled by the primary condenser 17 (outlet temperature 166°C), the elemental sulfur enters the liquid sulfur pool 11 to obtain liquid sulfur. The volume content of the reaction furnace tail gas 20 sulfur-containing compounds is: H 2 S: 8.12%, SO 2 : 4.03%, organic sulfur: 0.48%.

[0059] Reactor tail gas 20 enters the primary reactor 3 of the catalytic reaction section (reaction conditions: temperature 320°C, space velocity 800h -1 ) and secondary reactor 4 (reaction conditions: temperature 234 ° C...

Embodiment 2

[0062] process such as image 3 shown. The process includes thermal reaction section, catalytic reaction section and tail gas purification treatment section.

[0063] In the thermal reaction section, the acid gas 1 containing 94 (v / v)% hydrogen sulfide is partially burned in the reactor 2 and converted to sulfur dioxide. At a high temperature of 1260°C, hydrogen sulfide and sulfur dioxide undergo a Claus reaction to generate elemental sulfur and reactor tail gas. 20. After being cooled by the primary condenser 17 (outlet temperature 166°C), the elemental sulfur enters the liquid sulfur pool 11 to obtain liquid sulfur. The volume content of the reaction furnace tail gas 20 sulfur-containing compounds is: H 2 S: 8.12%, SO 2 : 4.03%, organic sulfur: 0.48%.

[0064] Reactor tail gas 20 enters the primary reactor 3 of the catalytic reaction section (reaction conditions: temperature 320°C, space velocity 800h -1 ) and secondary reactor 4 (reaction conditions: temperature 234 ° ...

Embodiment 3

[0067] process such as figure 2 shown. The process includes thermal reaction section, catalytic reaction section and tail gas purification treatment section.

[0068] In the thermal reaction section, the acid gas 1 containing 94 (v / v)% hydrogen sulfide is partially burned in the reactor 2 and converted to sulfur dioxide. At a high temperature of 1260°C, hydrogen sulfide and sulfur dioxide undergo a Claus reaction to generate elemental sulfur and reactor tail gas. 20. After being cooled by the primary condenser 17 (outlet temperature 166°C), the elemental sulfur enters the liquid sulfur pool 11 to obtain liquid sulfur. The volume content of the reaction furnace tail gas 20 sulfur-containing compounds is: H 2 S: 8.12%, SO 2 : 4.03%, organic sulfur: 0.48%.

[0069] Reactor tail gas 20 enters the primary reactor 3 of the catalytic reaction section (reaction conditions: temperature 320°C, space velocity 800h -1 ) and secondary reactor 4 (reaction conditions: temperature 234 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com