Preparation method of environmentally-friendly flame-retardant polyester bulked continuous filament

A technology of flame-retardant polyester and bulked filaments, which is applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyester artificial filaments, and conjugated synthetic polymer artificial filaments, etc., to achieve the effect of reducing the amount of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Polyester (PET) flame retardant bulked filament preparation (denier: 1500tex / 90F):

[0067] a. Preparation of styrene-acrylic copolymer microspheres modified by silane coupling agent;

[0068] Mix 28 parts of methacryloxypropyltrimethoxysilane, 22 parts of methyl methacrylate and 50 parts of styrene to form a monomer mixture; 1.5 parts of polyvinylpyrrolidone, 0.45 parts of dimethyl azobisisobutyrate 21 parts of ethanol and 21 parts of ethanol were stirred and dissolved to form a dispersion / initiator solution for later use; 130 parts of ethanol and 2.5 parts of polyvinylpyrrolidone were added to the reactor and stirred to dissolve, then 0.3 parts of dimethyl azobisisobutyrate and 1 / 2 amount of monomer mixture, and another 1 / 2 of the monomer mixture is added to the dropping tank; fill the reaction kettle and the dropping tank with nitrogen to 0.06MPa, exhaust to a slight positive pressure, and repeat 5 times; start stirring and heat up to 64~ 66°C, after 1 hour, start t...

Embodiment 2

[0086] Preparation of PTT bulked filament (denier: 1500tex / 90F):

[0087] a. Preparation of styrene-acrylic copolymer microspheres modified by silane coupling agent: same as Example 1

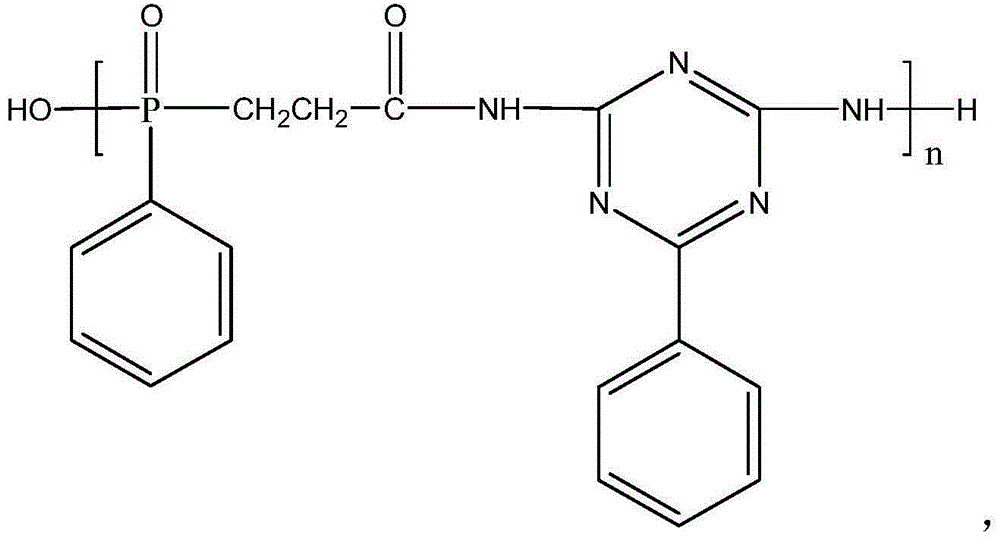

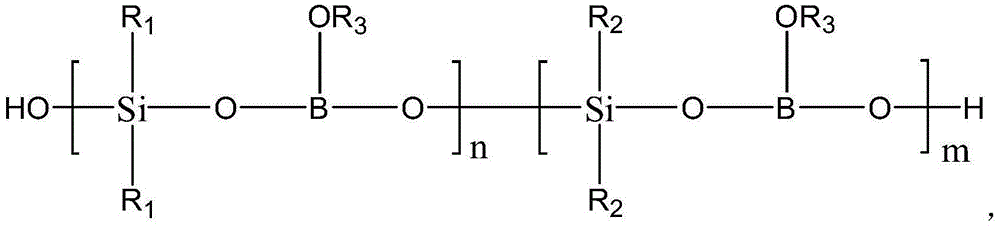

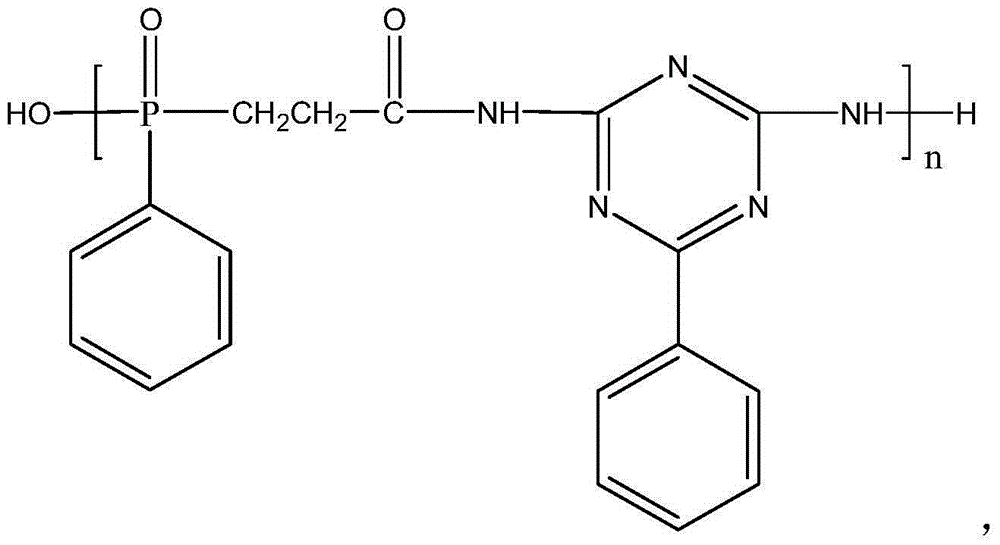

[0088] b. Preparation of flame retardant masterbatch: by weight, including the following raw materials: 22 parts of dried benzomelamine carboxyethylphenylphosphinic acid condensate, 7.5 parts of polyborosiloxane, and 11 parts of copolymer microspheres , 4 parts of superfine modified montmorillonite, 54 parts of butylene terephthalate and 1.5% of zinc stearate, mixed by a high-speed mixer, melted and blended by a twin-screw extruder, and granulated;

[0089] Among them: benzomelamine carboxyethylphenyl phosphinic acid condensation product condensation degree n=44-46; phenyl / methyl group on polyborosiloxane=70 / 30, condensation degree n+m=45.

[0090] c. Spinning: Add 75 parts of dried butylene terephthalate chips and 25 parts of flame-retardant masterbatch to the feeding screw of the BCF spinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com