A kind of preparation method of front electrode of thin-film solar cell

A technology for solar cells and front electrodes, applied in the field of materials science, can solve the problems of poor uniformity, uncontrollable triangular sheet morphology, poor absorption of visible light and infrared light, etc., so as to improve the uniformity and controllability, Highlight the substantive features and the effect of optimizing optical and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

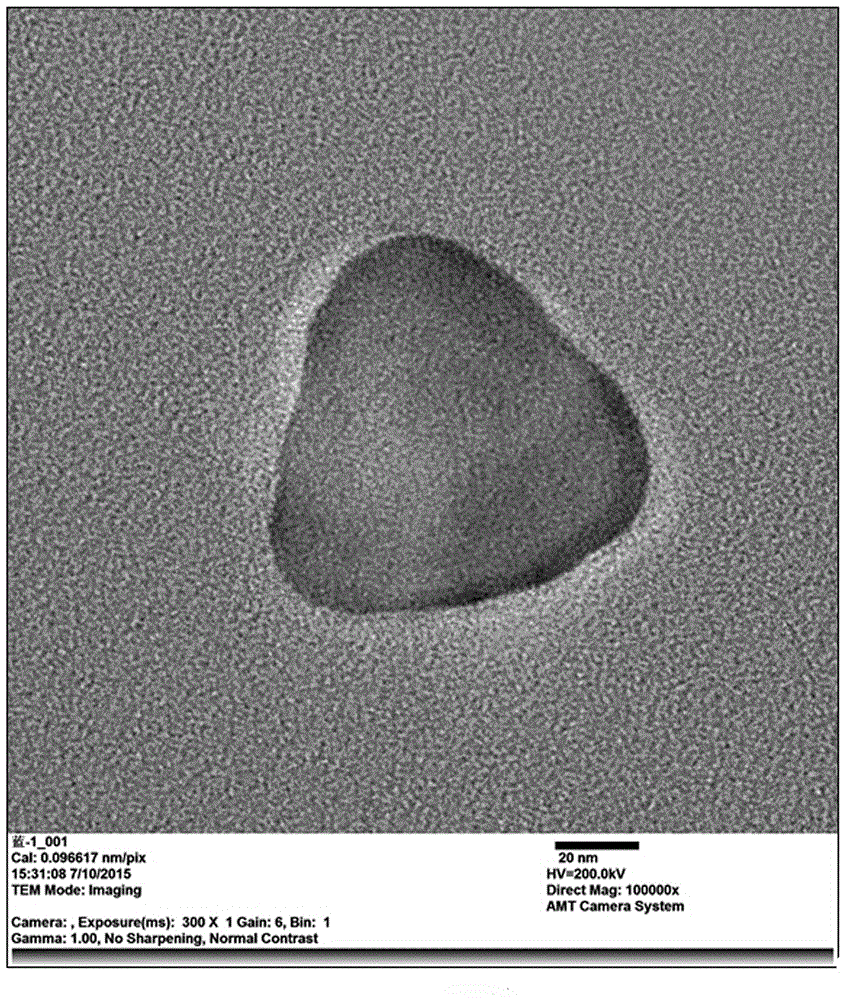

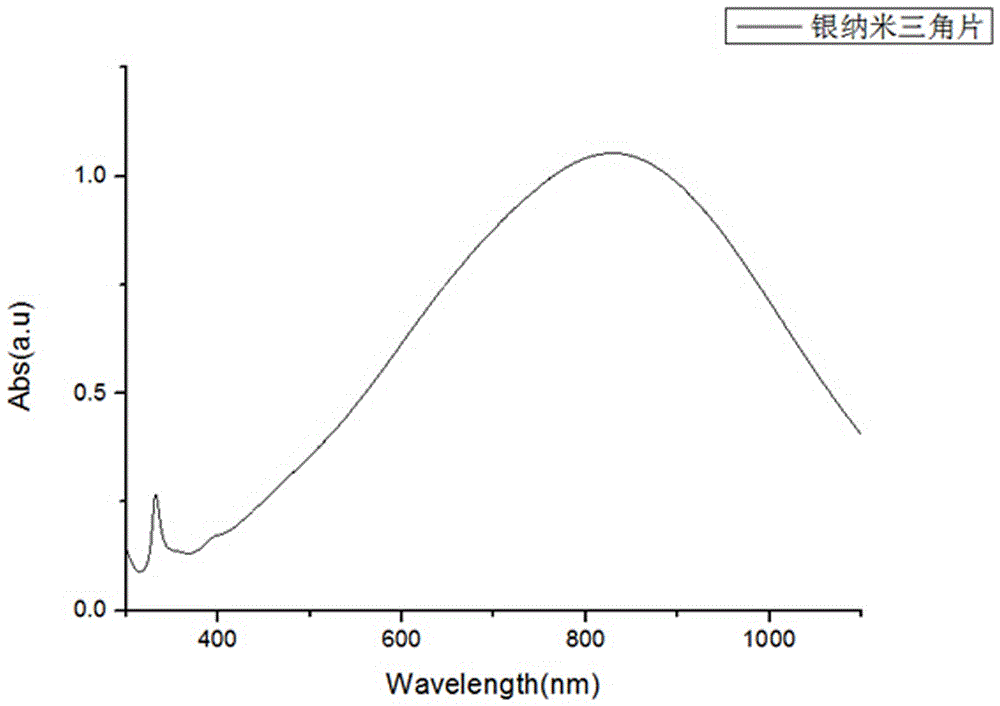

Image

Examples

Embodiment 1

[0025] A method for preparing a front electrode of a thin-film solar cell, comprising the following steps:

[0026] a. A step for preparing the AZO layer: using radio frequency magnetron sputtering equipment, under the sputtering power condition of 100w, under the atmosphere of argon gas of 10sccm, sputtering for 14min, the specific steps are as follows:

[0027] 1) Cut a common glass slide into a size of 1cm×1cm, ultrasonically clean the surface of the sample with acetone, ethanol and deionized water respectively, and then dry it with nitrogen;

[0028] 2) Open the magnetron sputtering chamber, install the target, and put the glass slide;

[0029] 3) Vacuum so that it reaches 2×10 -4 About Pa;

[0030] 4) Through argon, the flow rate of argon is 10sccm;

[0031] 5) Turn on the RF sputtering switch and adjust the sputtering power of 100w;

[0032] 6) Perform sputtering, and the sputtering time is 14 minutes.

[0033] b. A step for preparing an aqueous solution of silver n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com