Difunctional electrode with nitrification and denitrification activity and preparing method and application thereof

A nitrification-denitrification, dual-function technology, applied in the field of bioelectrochemistry, can solve the problems of high electrode production cost and low energy efficient utilization rate, and achieve the effects of reducing preparation cost and improving CODcr removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

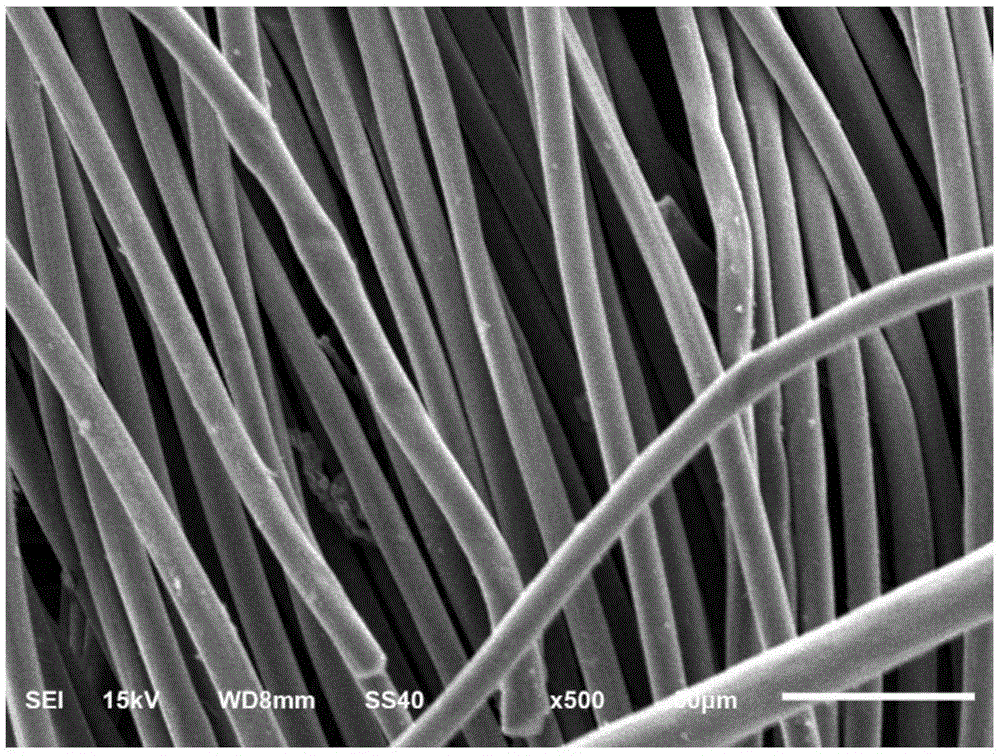

[0059] The carbon cloth of the cathode in this example was purchased from Cetech Company, the model is WOS1002.

[0060] The preparation process of the Bio / Pt bifunctional electrode is as follows (Bio represents microorganisms with nitrification and denitrification, and Pt is the oxygen reduction catalyst platinum purchased from the market):

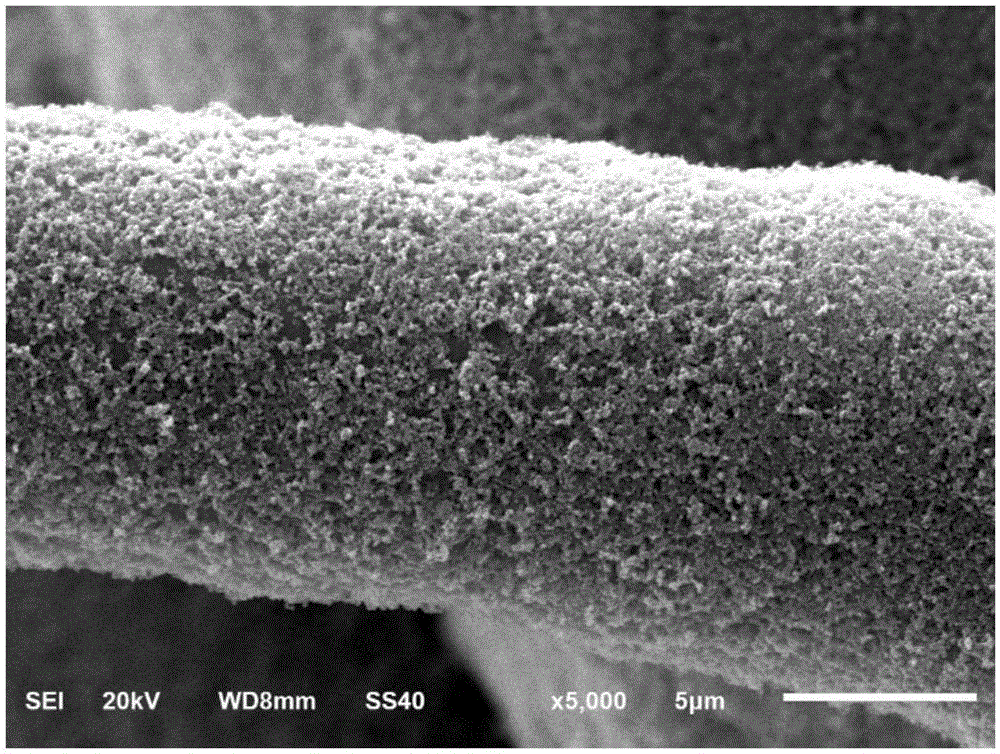

[0061] 1. Preparation of Pt cathode: Cut the carbon cloth into squares with a size of 3*3cm, soak in a solvent of absolute ethanol: acetone (V / V) ratio of 1:1 for 1 hour, and soak in 1mol / L HCl solution 1h, soak in 1mol / L NaOH solution for 1h to get a clean and impurity-free carbon cloth. After immersing in 10wt% PTFE for 1 hour, place it in an oven at 60°C to dry it, and place it in a muffle furnace to bake it at 370°C for 20 minutes to form a hydrophobic layer on the surface of the carbon cloth. The loading amount of Pt catalyst is taken as 0.5mg / cm 2 , that is, based on the calculation of 0.5mgPt catalyst loaded on the carbon cloth ...

Embodiment 2

[0085] The carbon paper for the cathode in this example was purchased from Cetech Company, the model is GDS210.

[0086] The preparation process of Bio / Au bifunctional electrode is as follows:

[0087] 1. Preparation of Au cathode: Cut the carbon paper into squares with a size of 3*3cm, soak in a solvent of absolute ethanol: acetone (V / V) (V / V) for 1:1 for 3 hours, and soak in 1mol / L HCl solution 3h, soak in 1mol / L NaOH solution for 3h to get clean carbon paper without impurities. After immersing in 10wt% PTFE for 3 hours, dry it in an oven at 80°C, and then bake it in a muffle furnace at 370°C for 15 minutes to form a hydrophobic layer on the surface of the carbon paper. The loading amount of Au catalyst is 0.1mg / cm 2 , that is, based on the calculation of 0.1mgAu catalyst loaded on the carbon paper per square centimeter, 9mg of 20wt% Au / C catalyst purchased from the market was weighed, that is, the mass percentage of Au was 20%, and 0.5mL / mg absolute ethanol was used as D...

Embodiment 3

[0091] The carbon felt for the cathode in this example is purchased from Cetech Company, model number is GF065.

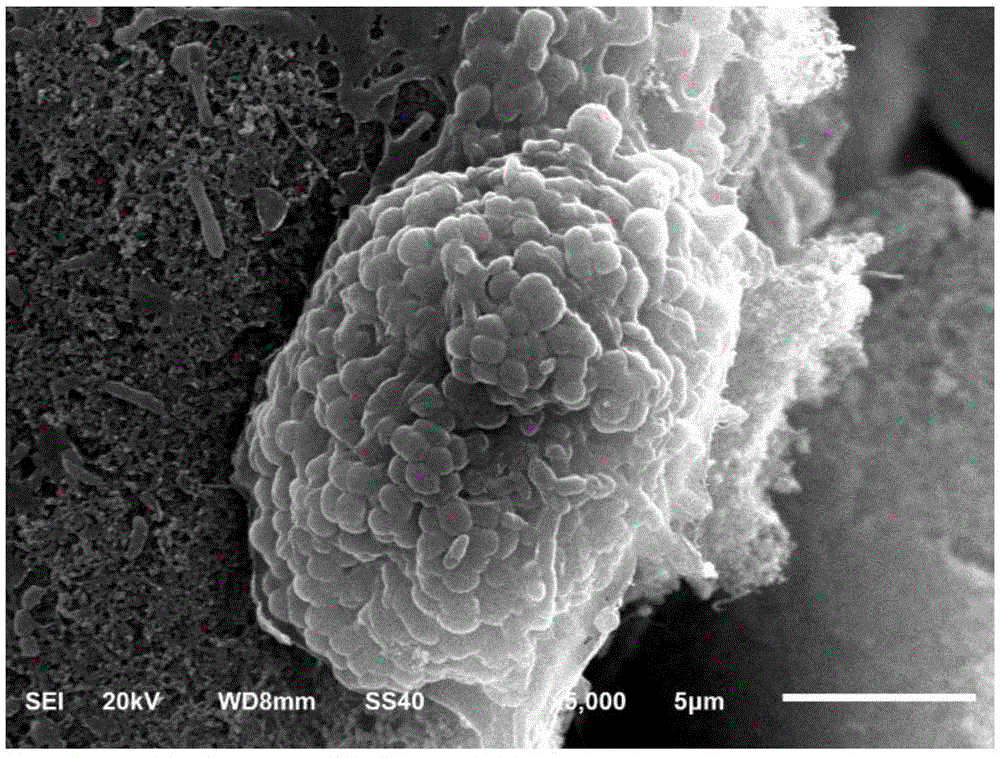

[0092] The preparation process of the Bio / NG bifunctional electrode is as follows:

[0093] 1. Preparation of graphite oxide (GO) material: Graphite oxide was prepared from natural flake graphite / carbon nanofiber material purchased from the market by the Hummers method, that is, a 250mL dry round bottom flask was placed in an ice bath, and 46ml concentrated Sulfuric acid (the mass fraction of sulfuric acid is 98%) and 0.5g sodium nitrate, mechanically stir this mixed solution, make sodium nitrate dissolve completely. When the temperature of the mixed solution is lower than 5°C, add 1g of graphite material, after mixing evenly, slowly add 3g of potassium permanganate, control the stirring speed and heating speed, so that the temperature of the reaction solution does not exceed 20°C. When the potassium permanganate was completely dissolved, the temperature of the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com