RSD-based pulse power supply module

A technology of pulse power supply and charging power supply, which is applied in the direction of electric pulse generator circuit and energy storage element to generate pulses, etc., which can solve the problems of large stray parameters of the circuit, short service life, slow switching speed, etc., and achieve high output current density, Effects of reducing parasitic inductance and reducing wire length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

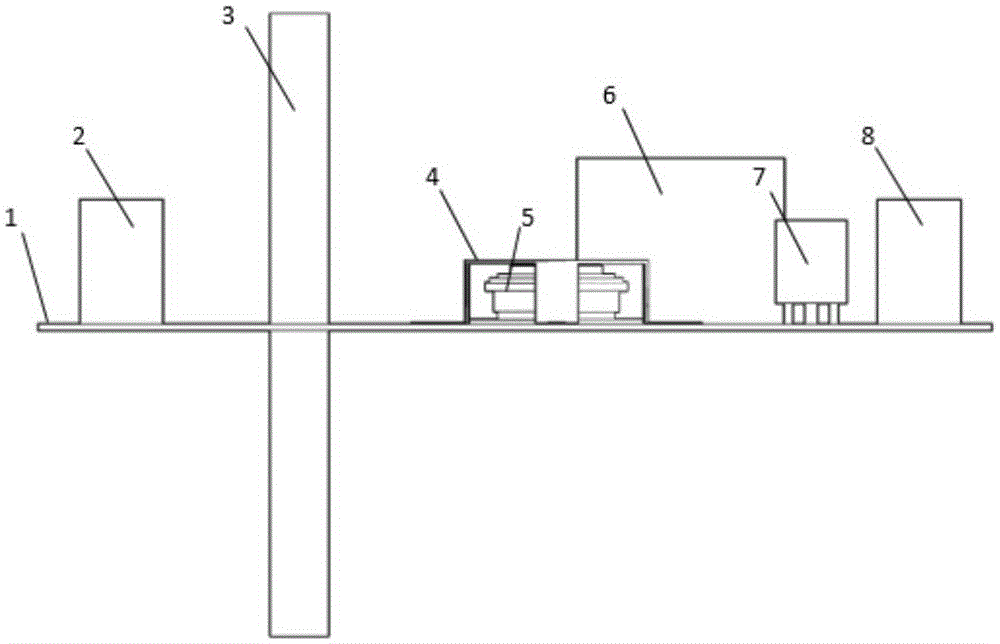

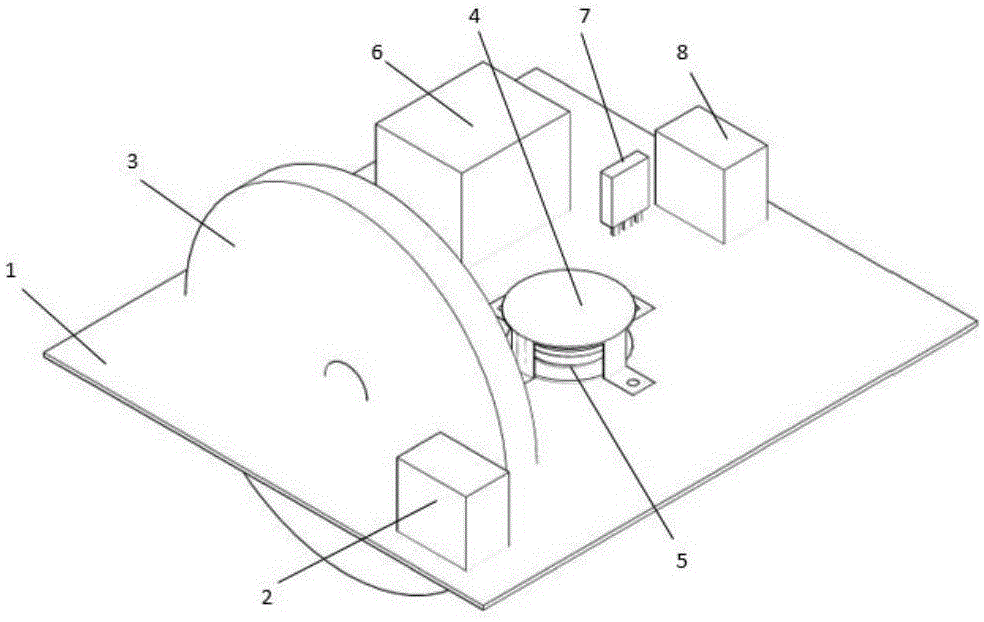

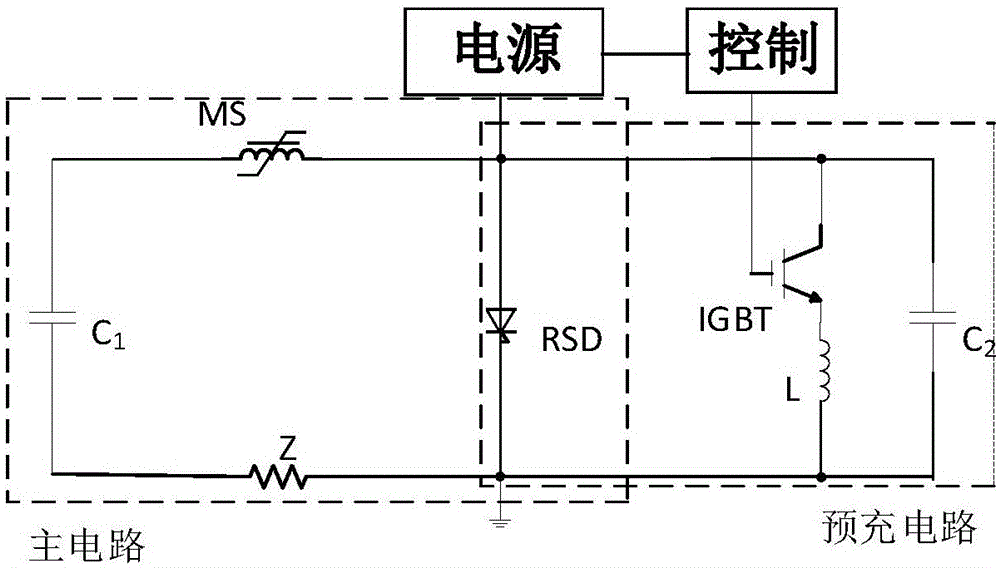

[0034] In Embodiment 1, in order to avoid the interference of the high current of the main circuit on the control module, the control module is formed into a separate board, which is composed of a general-purpose IGBT drive circuit and a TMS320X28 series DSP. The DSP outputs two complementary PWM waves, which are sent to the pre-charging source 6 respectively. And the driving circuit of IGBT7, when the pre-charging source 6 receives a high-level signal, IGBT7 receives a complementary low-level signal; when charging, the IGBT is disconnected, and the IGBT is turned on after charging, and the pulse power supply starts to work. Control the on-off of the charging power supply 6 and IGBT7 to realize the repetition frequency work of the pulse power supply;

[0035] In Example 1, the soldering of RSD5 and the surrounding copper foil 4 and PCB1 adopts a reflow soldering process, and the solder is made of lead-containing solder, which is soft and helps to reduce thermal stress; wherein,...

Embodiment 2

[0049] The difference between embodiment 2, embodiment 3 and embodiment 1 is that the tube core parameters of the RSD that the pulse power supply adopts are different, and the tube core of the RSD that embodiment 1 adopts is 1 inch, and the tube core of the RSD that embodiment 2 adopts is 2 inches. Inch, the tube core of the RSD that embodiment 3 adopts is 3 inches, and the size of RSD tube core is bigger, and corresponding RSD encapsulation profile is bigger, and the relevant parameters such as the withstand voltage of RSD are higher, and the output current of pulse power supply and repetition frequency are higher. High; as the size of the RSD changes, the parameters of the surrounding copper foil covering the RSD change accordingly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com