Fluorescence illuminating fluorescent material for detecting explosive, preparing method and application

A technology for fluorescent materials and explosives, applied in the field of fluorescent sensors, can solve the problems of difficult detection work, sensitivity to pollutants, high instrument cost, etc., and achieve the effects of simple preparation method, rapid fluorescence enhancement, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

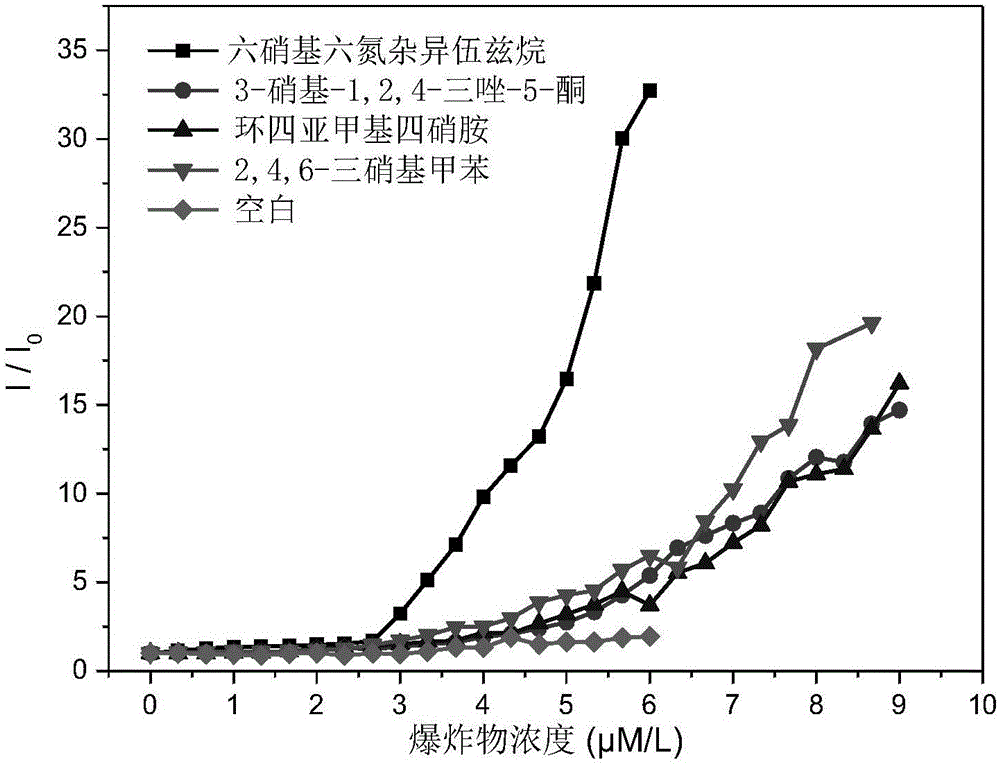

Examples

Embodiment 1

[0058] A fluorescent lighting-type fluorescent material M-TPP for detecting explosives, its preparation method and application:

[0059] (1) Preparation of M-TPP

[0060] Weigh 200mg (0.54mmol) of 1-p-bromophenyl-2,5-diphenylpyrrole (TPP), 87mg (0.64mmol) of p-tolylboronic acid, 32mg (0.027mmol) of tetrakis (triphenyl Phosphine) palladium, 229mg (2.16mmol) of anhydrous sodium carbonate in a 100mL two-necked bottle, vacuumize and fill with nitrogen to remove oxygen in the system, add 20mL of toluene and 5mL of methanol, react at 75°C for 24h, and the reaction is over Finally, toluene and methanol were removed by rotary evaporation to obtain solid 1; solid 1 was dissolved in dichloromethane, washed with water, and the organic phase was separated by column chromatography with petroleum ether / dichloromethane (1:1 by volume) as eluent, Rotary evaporation and recrystallization gave a white flocculent solid. Characterize the structure of the white flocculent solid by NMR and mass s...

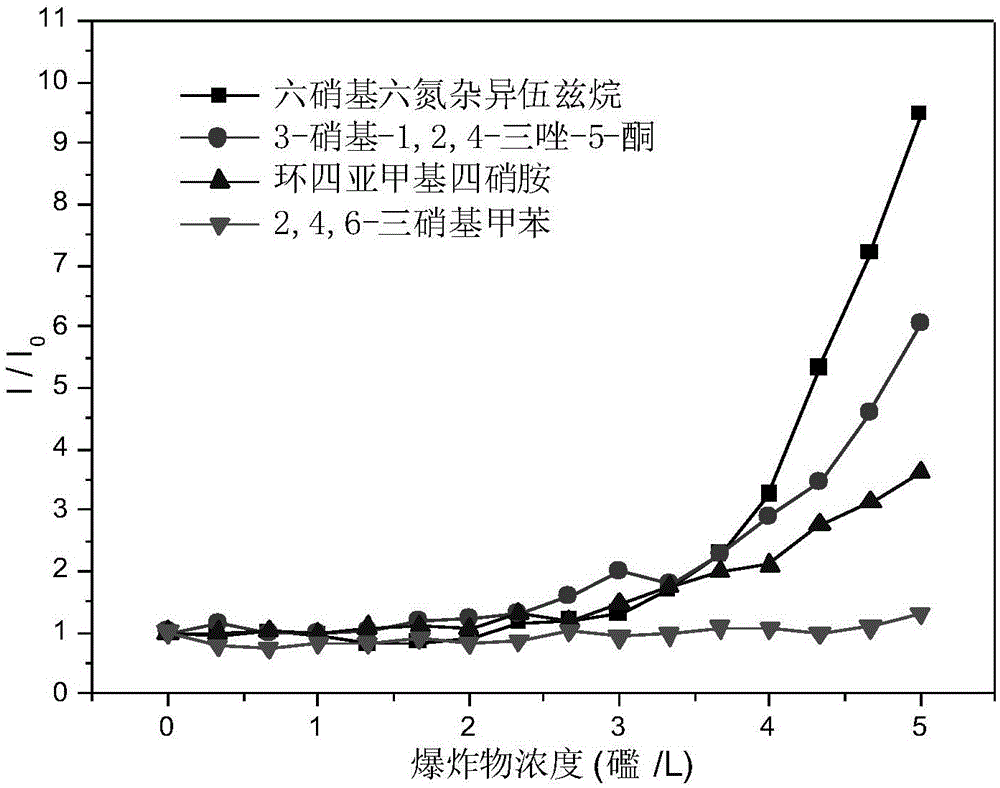

Embodiment 2

[0068] A fluorescent lighting-type fluorescent material M-TPP for detecting explosives, its preparation method and application:

[0069] (1) Preparation of M-TPP

[0070] Weigh 200mg (0.54mmol) of 1-p-bromophenyl-2,5-diphenylpyrrole (TPP), 87mg (0.64mmol) of p-tolylboronic acid, 32mg (0.027mmol) of tetrakis (triphenyl Phosphine) palladium, 229mg (2.16mmol) of anhydrous sodium carbonate in a 100mL two-necked bottle, vacuumize and fill with nitrogen to remove oxygen in the system, add 20mL of toluene and 5mL of methanol, react at 90°C for 14h, and the reaction ends Finally, toluene and methanol were removed by rotary evaporation to obtain solid 1; solid 1 was dissolved in dichloromethane, washed with water, and the organic phase was separated by column chromatography with petroleum ether / dichloromethane (1:1 by volume) as eluent, Rotary evaporation, recrystallization, obtain white flocculent solid; Characterize the structure of described white flocculent solid by NMR and mass s...

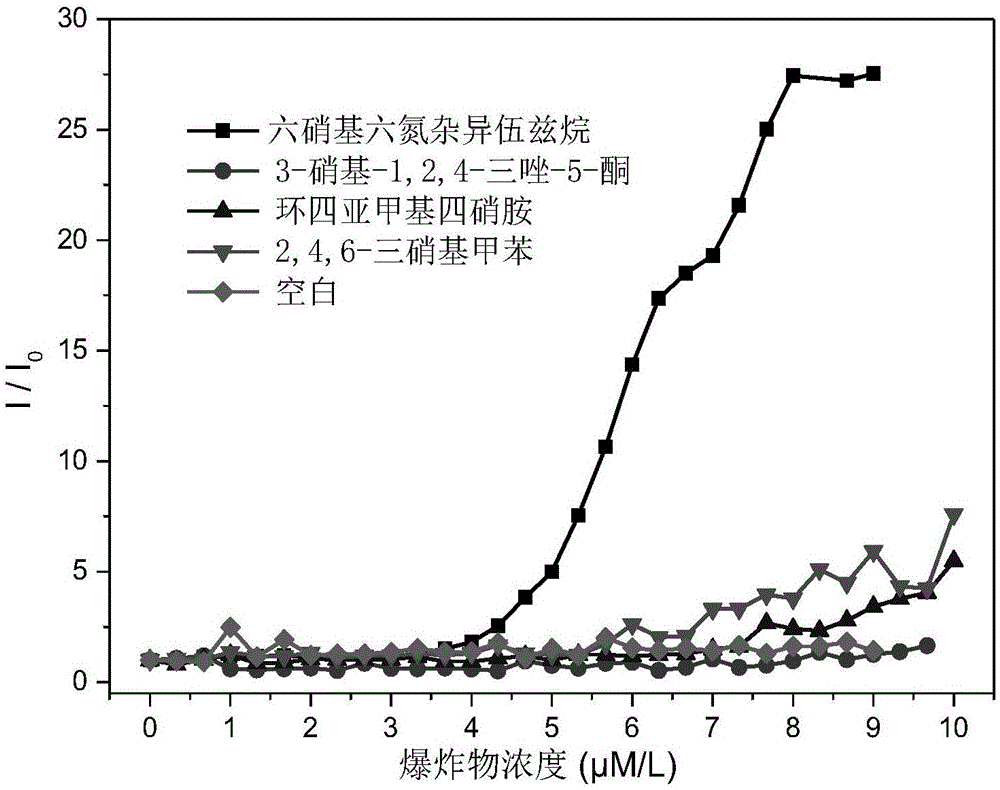

Embodiment 3

[0078] A fluorescent lighting-type fluorescent material V-TPP for detecting explosives, its preparation method and application:

[0079] (1) Preparation of V-TPP

[0080] ① 200mg (0.54mmol) of 1-p-bromophenyl-2,5-diphenylpyrrole (TPP), 88mg (0.64mmol) of p-hydroxyphenylboronic acid, 32mg (0.027mmol) of four (triphenylphosphine) ) and palladium, 229mg (2.16mmol) of anhydrous sodium carbonate were placed in a 100mL two-neck bottle, vacuumed and filled with nitrogen to remove oxygen in the system, 20mL of toluene and 5mL of methanol were added, and the reaction was stirred at 75°C for 24h After the reaction, toluene and methanol were removed by rotary evaporation to obtain solid 6; solid 6 was dissolved in dichloromethane to obtain solution c; solution c was added to an excess volume fraction of 5% dilute hydrochloric acid solution, acidified, Wash and separate the liquid, take the organic phase and use ethyl acetate / petroleum ether (volume ratio 1:3) as the eluent for column ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com