Electrolytic polishing solution for magnesium alloy medical heart stent and surface polishing processing technology of medical heart stent

A heart stent and electrolytic polishing technology, which is applied in the field of metal surface polishing liquid, can solve the problems of poor controllability of polishing quality, low cost of chemical polishing, thrombus and intimal hyperplasia, etc., so as to reduce the difficulty of processing, shorten the time of polishing electrolysis, and reduce the reaction time. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

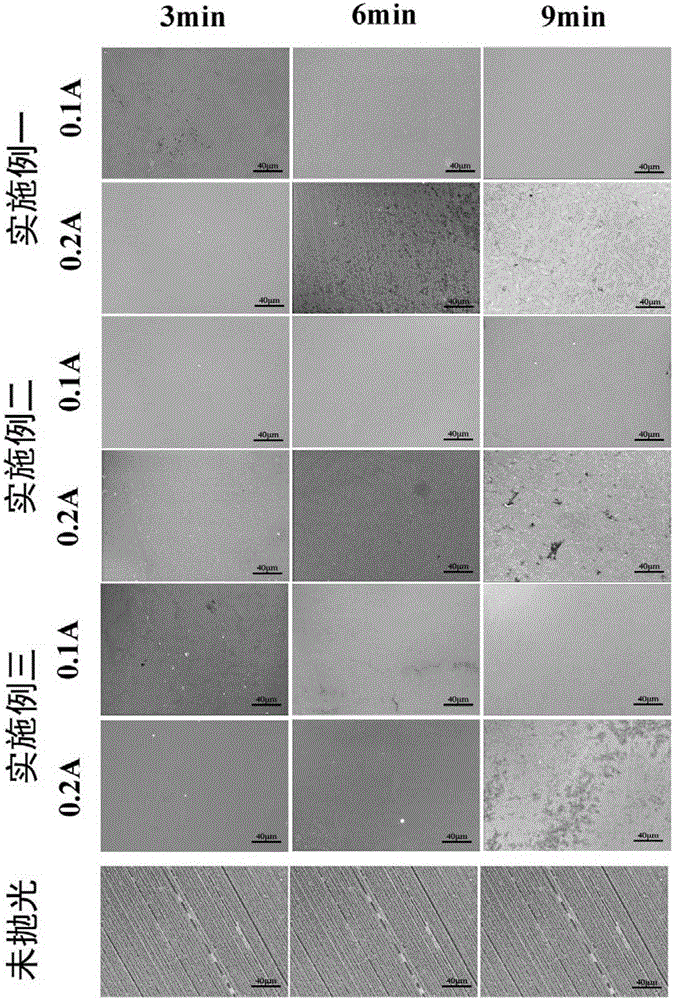

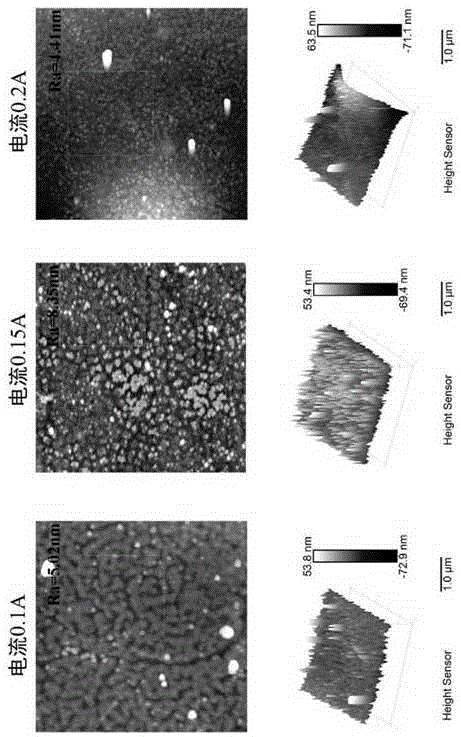

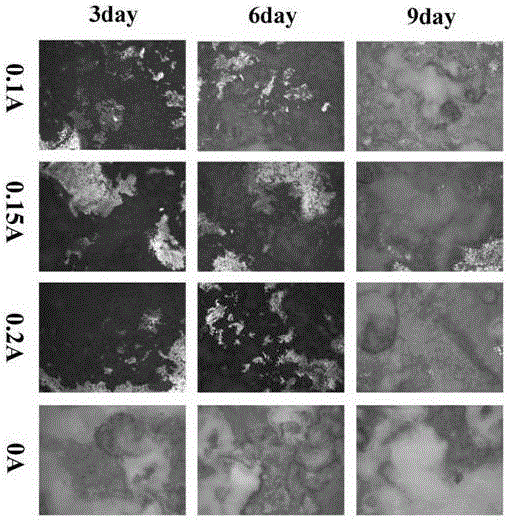

Embodiment 1

[0046] The surface polishing treatment process of the magnesium alloy medical heart stent according to the first embodiment of the present invention is carried out according to the following steps.

[0047] a. Mechanical grinding and polishing: The magnesium alloy material is cut into a semi-finished magnesium alloy medical heart stent by wire cutting, which is ground and polished to #2000 sandpaper by a grinding and polishing machine, and then polished with a diamond polishing paste with a diameter of 0.25 μm. b. Degreasing treatment: Add 200ml of acetone with an analytically pure concentration into a 1000ml beaker, place the semi-finished product obtained in step a in the beaker, and clean it with ultrasonic vibration at 25°C for 30 minutes. c. Ultrasonic vibration alkali cleaning: In a 1000ml beaker filled with 150ml deionized water, add 1.0g of analytically pure sodium hydroxide to prepare lye, place the semi-finished product obtained in step b in the beaker, and heat it at...

Embodiment 2

[0053] The surface polishing process of the magnesium alloy medical heart stent according to the second embodiment of the present invention is carried out according to the following steps.

[0054] a. Mechanical grinding and polishing: The magnesium alloy material is cut into a semi-finished magnesium alloy medical heart stent by wire cutting, which is ground and polished to #2000 sandpaper by a grinding and polishing machine, and then polished with a diamond polishing paste with a diameter of 0.25 μm.

[0055] b. Degreasing treatment: Add 200ml of acetone with a concentration of analytical grade to a 1000ml beaker, place the semi-finished product obtained in step a in the beaker, and clean it with ultrasonic vibration at 45°C for 20 minutes.

[0056] c. Ultrasonic vibration alkali cleaning: In a 1000ml beaker filled with 150ml deionized water, add 2.0g of analytically pure sodium hydroxide to make lye, place the semi-finished product obtained in step b in the beaker, and heat ...

Embodiment 3

[0062] The surface polishing treatment process of the magnesium alloy medical heart stent according to the third embodiment of the present invention is carried out according to the following steps.

[0063] a. Mechanical grinding and polishing: The magnesium alloy material is cut into a semi-finished magnesium alloy medical heart stent by wire cutting, which is ground and polished to #2000 sandpaper by a grinding and polishing machine, and then polished with a diamond polishing paste with a diameter of 0.25 μm.

[0064] b. Degreasing treatment: Add 200ml of acetone with an analytically pure concentration into a 1000ml beaker, place the semi-finished product obtained in step a in the beaker, and clean it with ultrasonic vibration at 25°C for 30 minutes.

[0065] c. Ultrasonic vibration alkali cleaning: In a 1000ml beaker filled with 150ml deionized water, add 1.5g of analytically pure sodium hydroxide to prepare lye, place the semi-finished product obtained in step b in the beak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com