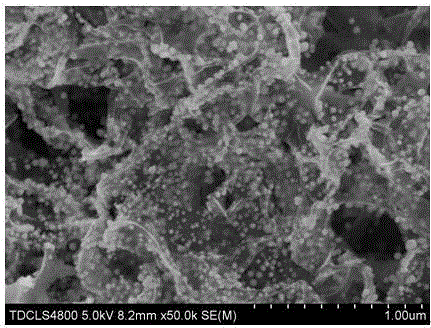

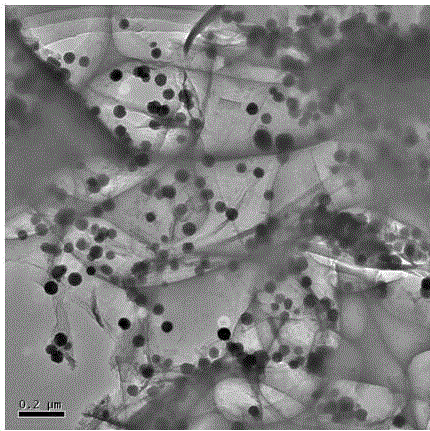

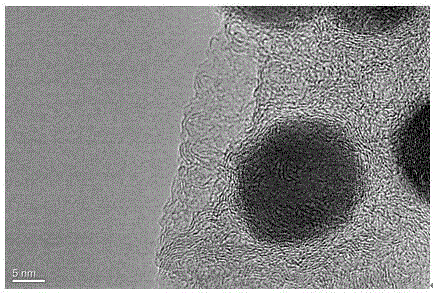

Three-dimensional composite material formed by filling carbon-encapsulated tin granules into graphene interlaminations and by filling graphene layers with carbon-encapsulated tin granules and preparation method for three-dimensional composite material

A graphene layer and composite material technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as difficult preparation, and achieve the effects of strong controllability, high specific capacity, and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 2.5g citric acid, 0.384g stannous chloride and 9.8gNaCl, dissolve the mixture in 50ml of deionized water, stir and dissolve to form a solution with a magnetic stirrer with a stirring speed of 300r / min, and then use a power of 400W Ultrasound for 15min, mix well. Put the mixed solution in the refrigerator to freeze overnight, and then place it in a freeze dryer to dry under vacuum at -50°C until the mixture is dried. Grind the mixture, take 10g and place it in the ark, put the ark into the tube furnace, pass through 200ml / min Ar inert gas for 10min to remove the air, then use 200ml / min Ar inert gas, and heat up at 10°C / min The temperature was raised to a temperature of 400° C., and the temperature was kept for 1 hour for carbonization reaction. After the reaction was completed, it was cooled to room temperature under the protection of an Ar atmosphere to obtain a calcined product A. Collect the calcined product A, grind it finely, wash with water until there is no...

Embodiment 2

[0028]Weigh 2.5g of citric acid, 0.576g of stannous chloride and 14.7g of NaCl, dissolve the mixture in 50ml of deionized water, stir and dissolve to form a solution with a magnetic stirrer with a stirring speed of 300r / min, and then use a power of 400W Ultrasound for 15min, mix well. Put the mixed solution in the refrigerator to freeze overnight, and then place it in a freeze dryer to dry under vacuum at -50°C until the mixture is dried. Grind the mixture, take 10g of the mixed powder and place it in the ark, put the ark into the tube furnace, pass through the Ar inert gas of 200ml / min for 10min to remove the air, and then use the Ar inert gas of 200ml / min at 10℃ / min The temperature was raised to 400°C at a heating rate of 1 min, and the carbonization reaction was carried out at a temperature of 1 h. After the reaction was completed, it was cooled to room temperature under the protection of an Ar atmosphere, and the calcined product A was obtained. Collect the calcined produ...

Embodiment 3

[0030] Weigh 2.5g citric acid, 0.576g stannous chloride and 29.4gNaCl, dissolve the mixture in 50ml of deionized water, stir and dissolve to form a solution with a magnetic stirrer with a stirring speed of 300r / min, and then use a power of 400W Ultrasound for 15min, mix well. Put the mixed solution in the refrigerator to freeze overnight, and then place it in a freeze dryer to dry under vacuum at -50°C until the mixture is dried. Grind the mixture, take 10g of the mixed powder and place it in the ark, put the ark into the tube furnace, pass through the Ar inert gas of 200ml / min for 10min to remove the air, and then use the Ar inert gas of 200ml / min at 10℃ / min The temperature was raised to 300°C at a heating rate of 1 min, and the carbonization reaction was carried out at a heat preservation time of 2 hours. After the reaction was completed, it was cooled to room temperature under the protection of an Ar atmosphere to obtain the calcined product A. Collect the calcined product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com