A strain of Bacillus subtilis with high production of mesophilic α-amylase and its liquid fermentation method

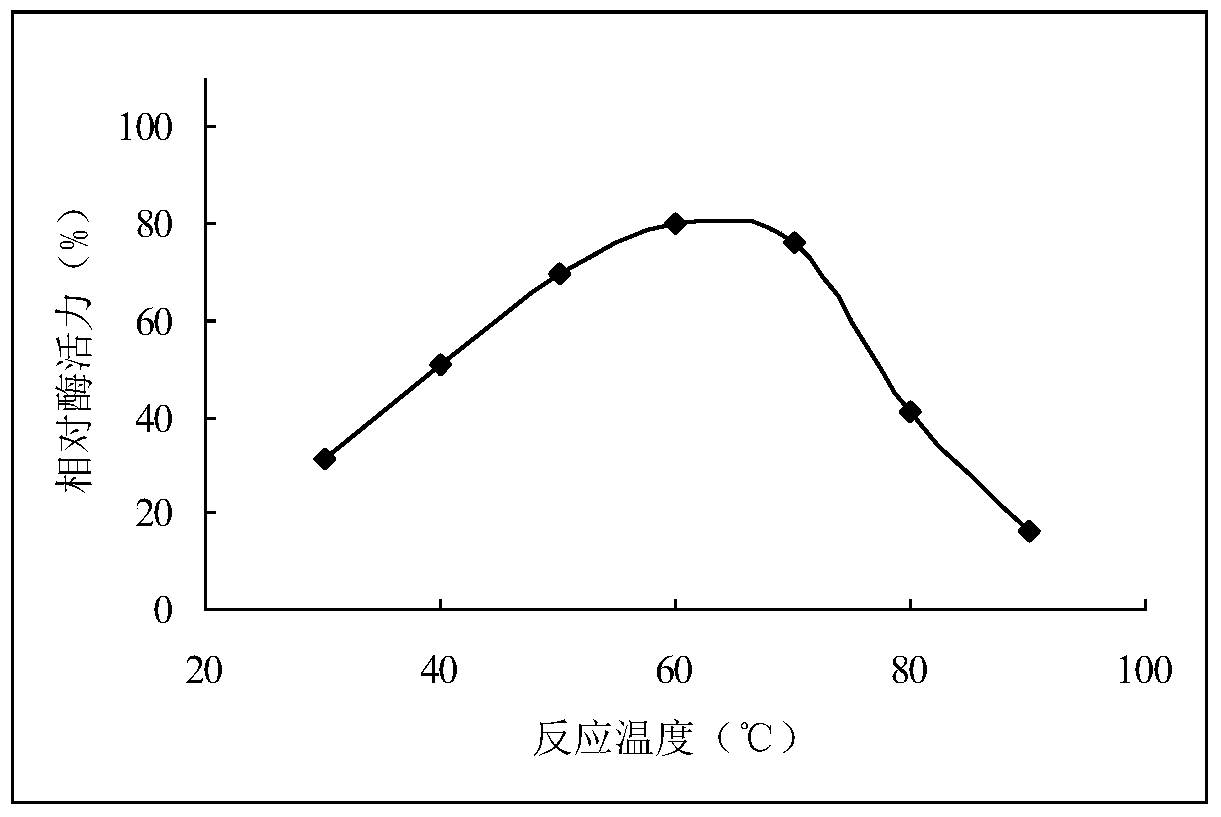

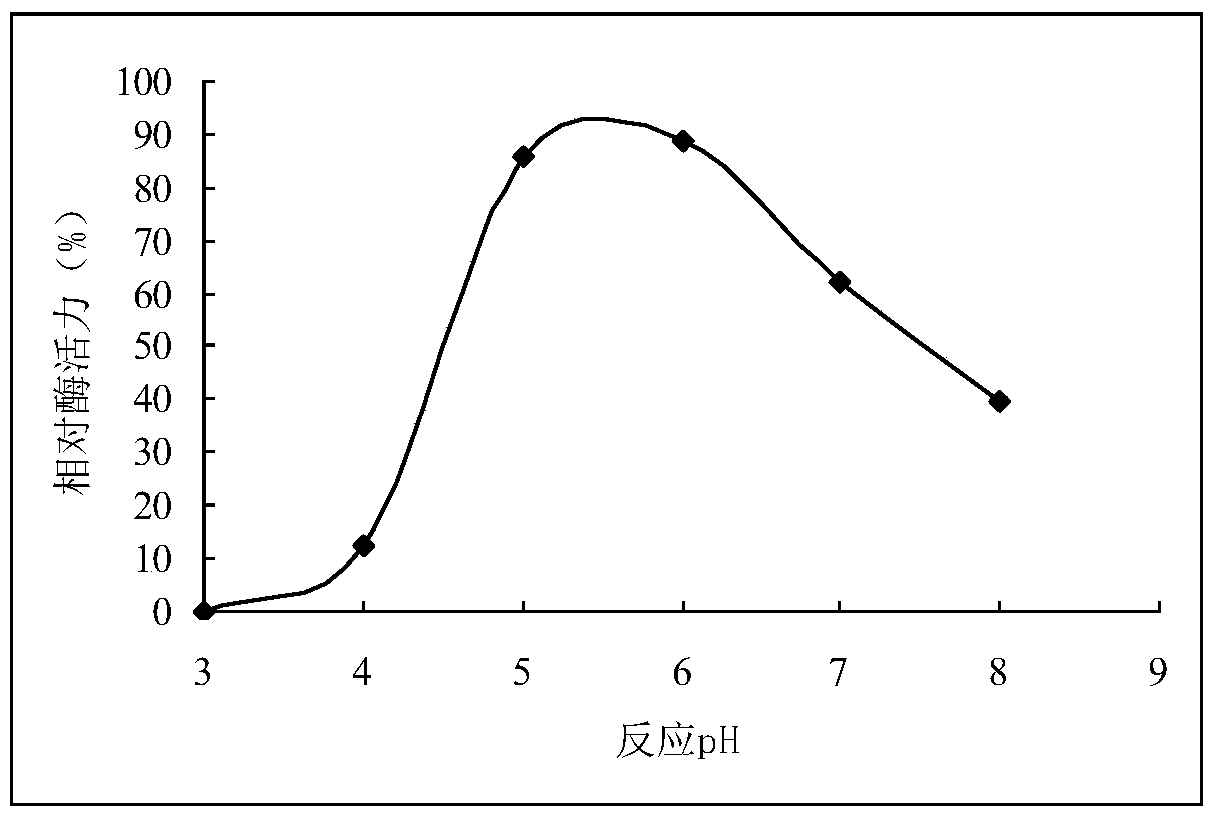

A technology of Bacillus subtilis and amylase, applied in the field of microbial breeding and fermentation, can solve the problem of unsatisfactory maximum enzyme activity, and achieve the effects of wide pH value range, high fermentation enzyme activity and strong antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the breeding of bacterial strain

[0023] (1) Bacterial suspension preparation:

[0024] Centrifuge the Bacillus subtilis BS2007 bacterial solution cultivated to the logarithmic phase at 8000 rpm for 5 minutes, discard the supernatant, and resuspend it with 10% glycerol to obtain the bacterial suspension. The cell concentration of the bacterial suspension is at 10 7 pieces / ml.

[0025] (2) ARTP mutagenesis:

[0026] Suck 10 μL of bacterial suspension into the center of the slide and spread it evenly; use sterile tweezers to place the slide on the corresponding hole on the rotating platform of the ARTP system operating room, adjust the knob below the slide to make the slide 2mm from the airflow port, and set The air flow is 10SLM, the power is adjusted to 100W, and the mutagenic irradiation time is selected as 20s, 25s, and 30s respectively; after the sample is processed, use sterile tweezers to move the slide to the EP tube containing 1mL of normal salin...

Embodiment 2

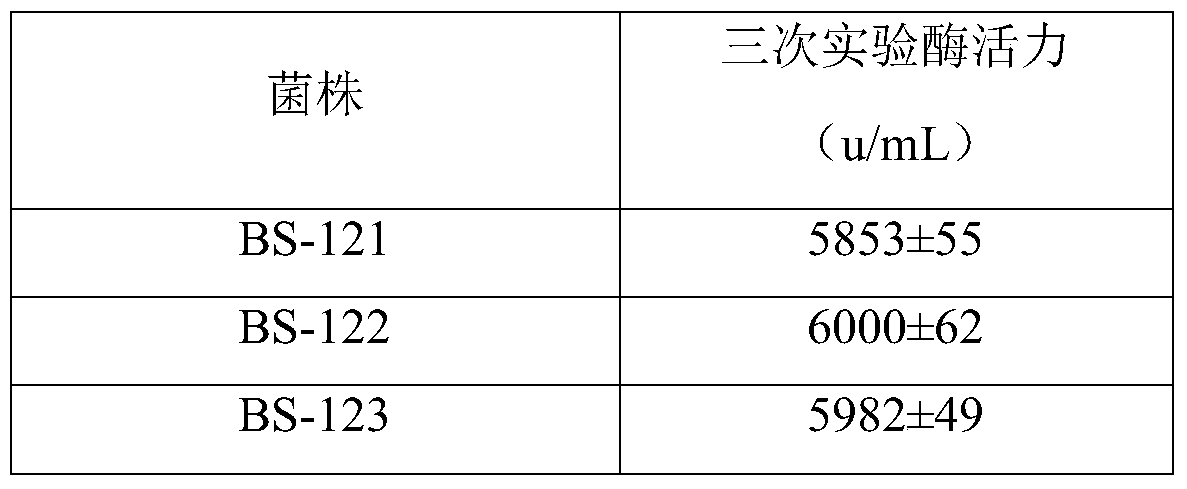

[0033] Embodiment 2: Liquid fermentation produces mesophilic alpha-amylase

[0034] The liquid fermentation method after the optimization of the medium formula and the optimization of the fermentation process is as follows.

[0035] Technological process: preservation of strains→slope activation→plate culture→seed liquid shake bottle culture→fermentation culture in 50L fermenter→extraction and refining

[0036] Seed culture: The 3 mutagenic strains screened by shake flasks were cultured in conventional shake flasks to make seed liquid, and the volume of liquid in a 500mL Erlenmeyer flask was 50mL. The shake flask medium formula is: 3% soluble starch, 0.3% yeast extract, 0.3% peptone, 0.2% calcium chloride, the rest is water, pH 6.5; the culture conditions are: temperature 37°C, rotation speed 200rpm, culture period 6h;

[0037] Liquid fermentation: Liquid fermentation is carried out in a 50L fermenter. The composition of the fermentation medium is: 6% corn flour, 3% bean cake ...

Embodiment 3

[0046] Embodiment 3: the antibacterial property test of mutant strain

[0047] Preparation of the crude cell extract: take the fermentation liquid of the strain BS-122 fermented to 40h, centrifuge at 8000r / min at 4°C for 5min to remove the cell, take the supernatant and filter it through a bacterial filter (0.22μm) to obtain the crude cell extract .

[0048] Use the Oxford cup quantitative diffusion method to test the resistance to the test fungus: put the sterilized Oxford cup into the center of a petri dish with a diameter of 9 cm, pour the melted solid PDA medium into the plate under aseptic conditions, and wait for it to solidify Finally, take out the Oxford cup, inoculate 3 pieces (diameter 5mm) of indicator bacteria of substantially the same size on the edge of the petri dish equidistantly, and add 180 μl of the crude extract of the mutant bacteria or the original bacteria to the Oxford cup in the medium. Cultivate at 28°C, and measure the diameter of the inhibition zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com