Foam aluminum with three-dimensional (3D) space ordered pore structure and preparation method thereof

A three-dimensional space and pore structure technology, applied in heat exchange equipment, rotors, cylinders, etc., can solve the problems of poor porosity and pore structure uniformity and connectivity, and can not arbitrarily control and adjust structural parameters, and achieve excellent compression performance, good Energy absorption characteristics, uniform pore size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1. The aluminum block and the magnesium block are melted in a vacuum furnace according to the ratio of Al-2.5Mg to form an alloy liquid, and the melting temperature is 690° C., wherein the purity of the aluminum block and the magnesium block is greater than 99.5%.

[0028] Step 2. Mix 1% of silane coupling agent, 20% of composite polyamine curing agent, and the rest of asphalt to make bonding powder, mix 30% of bonding powder with 70% graphite for ball milling, and graphite It is natural flake graphite, passed through a 200-mesh sieve to obtain 3D printed powder;

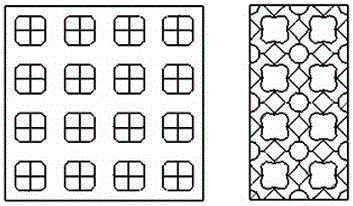

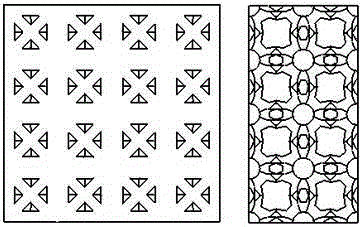

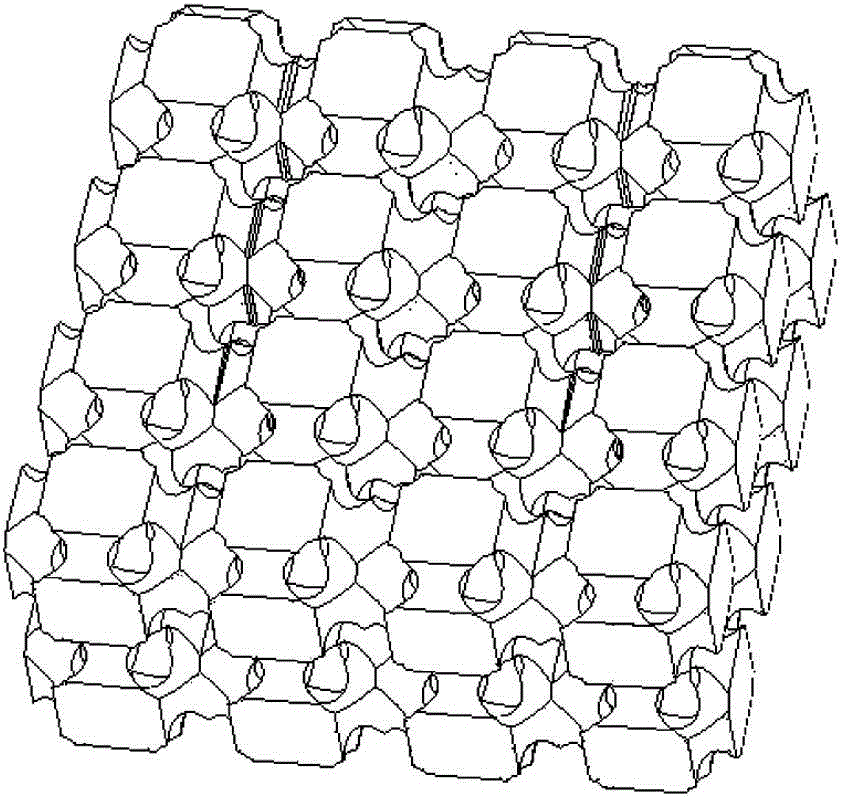

[0029] Step 3. Use 3D printing laser sintering powder to obtain graphite skeleton 1 with an ordered structure of three-dimensional space network. 4 diagonal lines through the central point, where the diameter of the graphite skeleton is 2mm, such as figure 1 shown;

[0030] Step 4, graphitize the graphite skeleton obtained with the ordered structure of the three-dimensional space network, place the gra...

Embodiment 2

[0033] Step 1. The aluminum block and the magnesium block are melted into alloy liquid in a vacuum furnace according to the ratio of Al-2Mg, the melting temperature is 690°C, and the purity of the aluminum block and the magnesium block is greater than 99.5%.

[0034] Step 2. Mix 1% of silane coupling agent, 20% of composite polyamine curing agent, and the rest of asphalt to make bonding powder, mix 30% of bonding powder with 70% graphite for ball milling, and graphite It is natural flake graphite, passed through a 200-mesh sieve to obtain 3D printed powder;

[0035] Step 3. Use 3D printing laser sintering powder to obtain graphite skeleton 2 with an ordered three-dimensional space. The difference from graphite skeleton 1 is that on the basis of graphite skeleton 1, there are six diagonals of body-centered cubic planes. The skeleton of the corner line is 12 graphite skeletons of 1mm, such as figure 2 shown;

[0036] Step 4, graphitize the graphite skeleton obtained with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com