Denim accelerating agent and preparation method thereof

A technology of dye accelerator and denim fabric, applied in the field of dye accelerator, it can solve the problems of small amount of dye used, influence of fabrics, physical influence of workers, etc., and achieve the effect of simplifying process, reducing load and shortening time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

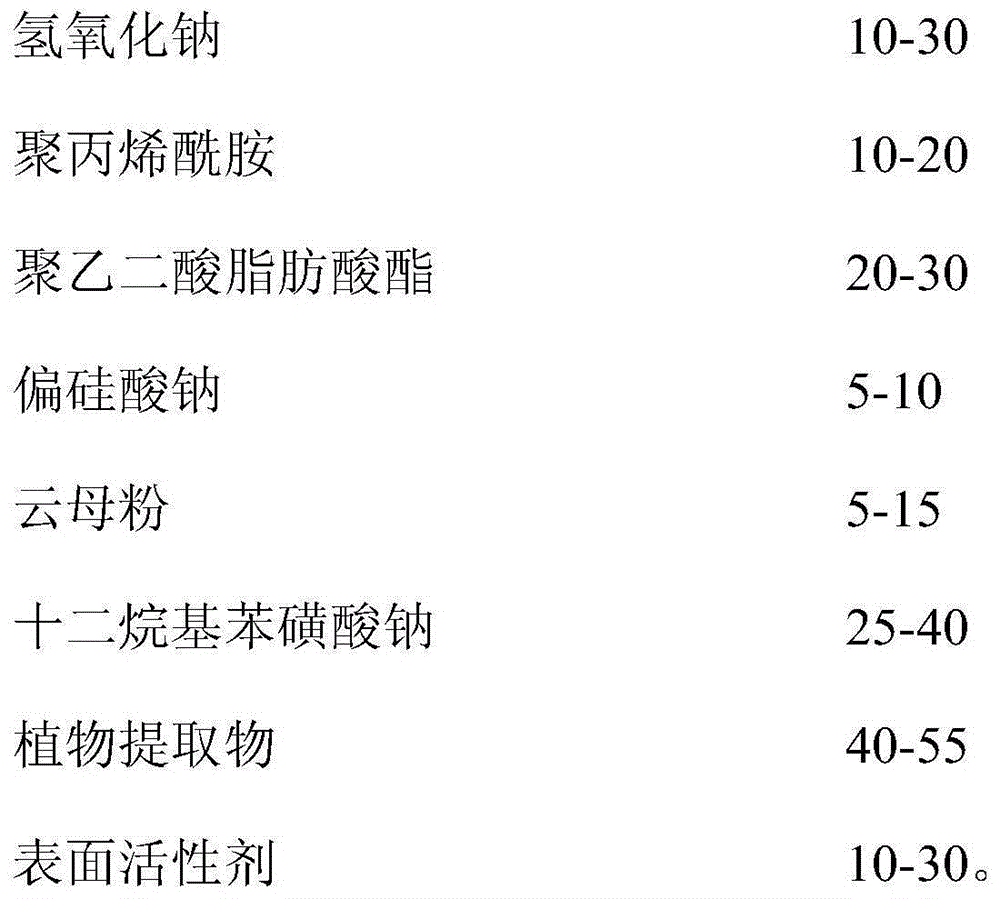

[0030] Each raw material of a denim dyeing accelerator comprises by weight:

[0031]

[0032] Wherein the particle size of sodium hydroxide is: 0.05mm, the weight average molecular weight of polyacrylamide is 50000Da, and the weight average molecular weight of polyoxalic acid fatty acid ester is 3000Da.

[0033] Wherein the plant extract is a mixture of camphor leaf extract, white orchid extract, Chuanqiong extract and dendrobium extract, and the surfactant is sodium glyceryl laurate sulfate. The preparation method is as follows: the raw materials are poured into a stirred tank according to the weight parts, and stirred at a speed of 40 rpm for 3 minutes at a temperature of 30°C.

Embodiment 2

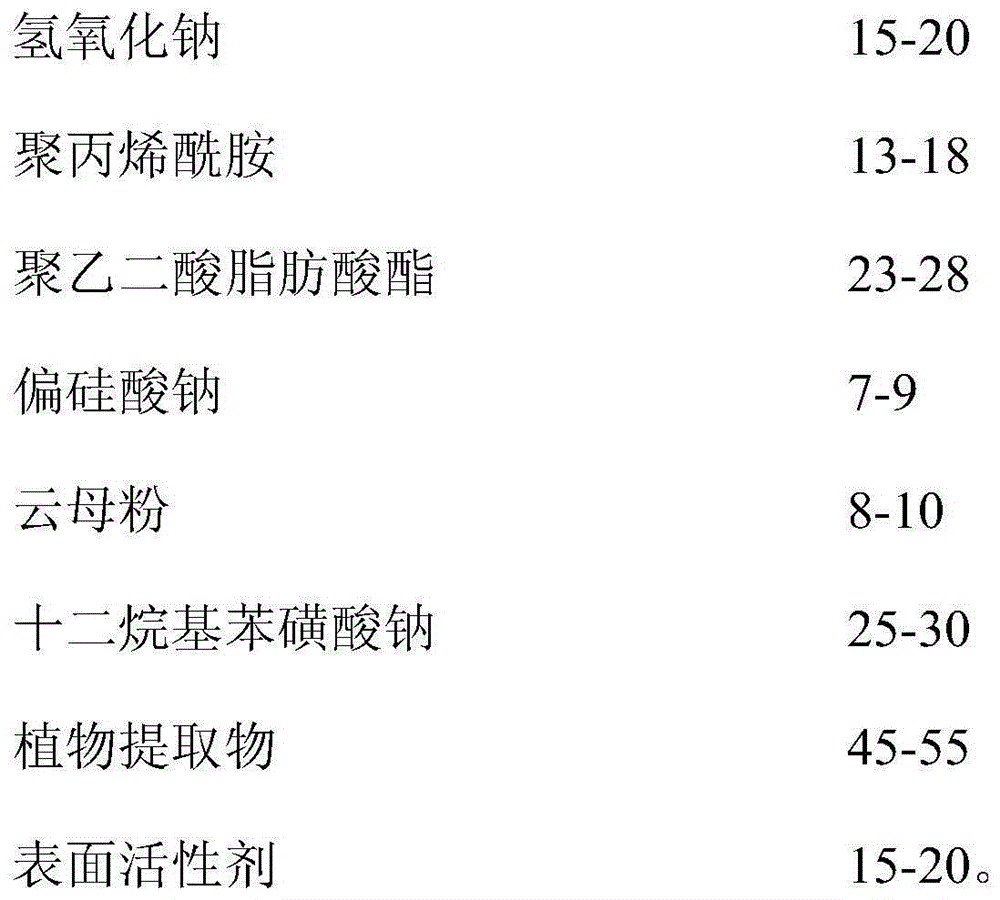

[0035] Each raw material of a denim dyeing accelerator comprises by weight:

[0036]

[0037] The particle size of sodium hydroxide is 0.3mm, the weight average molecular weight of polyacrylamide is 70000Da, and the weight average molecular weight of polyoxalic acid fatty acid ester is 5000Da.

[0038] Wherein the plant extract is a mixture of camphor leaf extract, white orchid extract and dendrobium extract, and the surfactant is sodium glyceryl laurate sulfate. The preparation method is as follows: the raw materials are poured into a stirred tank according to the weight parts, and stirred at a speed of 50 rpm for 3 minutes at a temperature of 40°C.

Embodiment 3

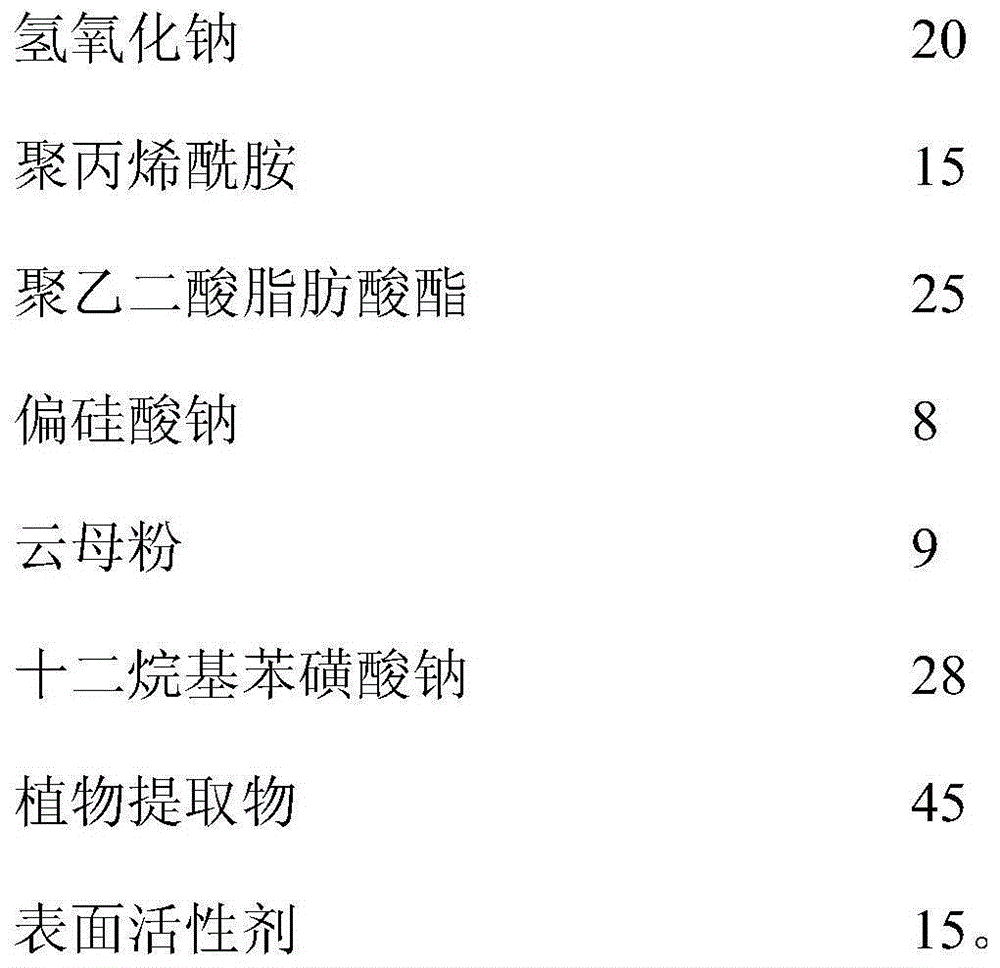

[0040] Each raw material of a denim dyeing accelerator comprises by weight:

[0041]

[0042]

[0043] The particle size of sodium hydroxide is 0.2mm, the weight average molecular weight of polyacrylamide is 70000Da, and the weight average molecular weight of polyoxalic acid fatty acid ester is 10000Da.

[0044] Wherein the plant extract is a mixture of camphor leaf extract, Chuanqiong extract and dendrobium extract, and the surfactant is sodium glycerol laurate sulfate. The preparation method is as follows: the raw materials are poured into a stirred tank according to the weight parts, and stirred at a speed of 45 rpm for 5 minutes at a temperature of 35°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com