Production method for extracting phosphorite cogeneration feed grade monocalcium phosphate and industrial grade monoammonium phosphate

A technology of high-grade ammonium dihydrogen phosphate and calcium dihydrogen phosphate is applied in the field of wet-process phosphoric acid extraction of phosphate rock to co-produce feed-grade calcium dihydrogen phosphate and industrial-grade ammonium dihydrogen phosphate, which can solve the problem of feed-grade calcium dihydrogen phosphate Quality requirements, large impact on the ecological environment, and large damage to the ecological environment, etc., to achieve high biological potency, good feeding efficiency, and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

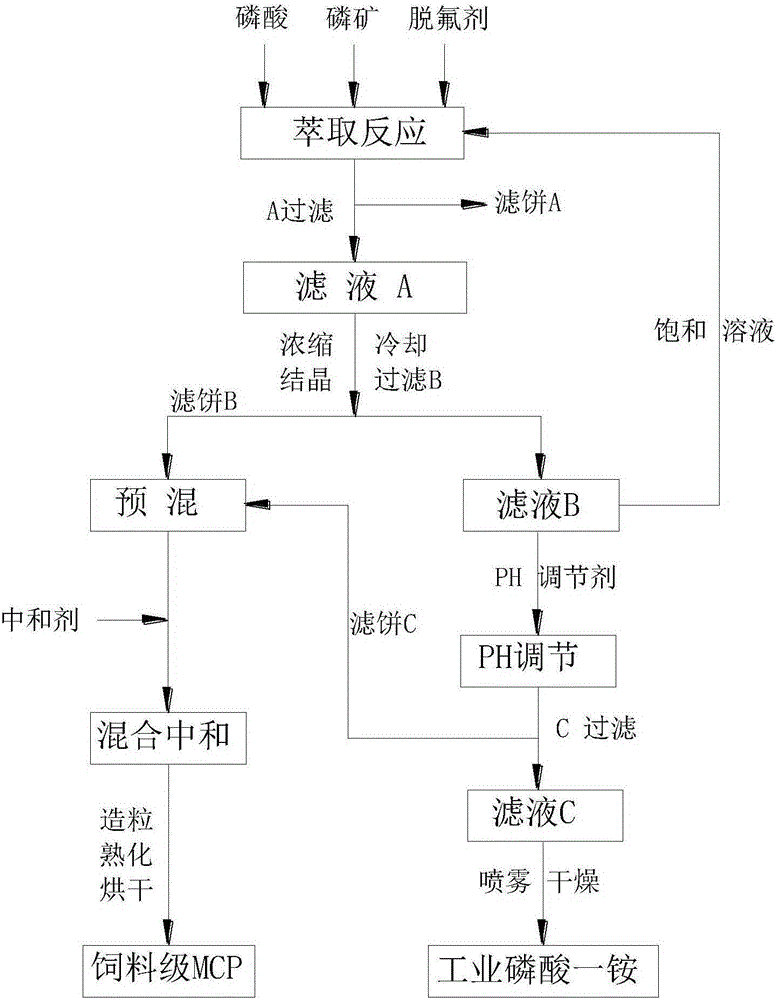

Method used

Image

Examples

Embodiment 1

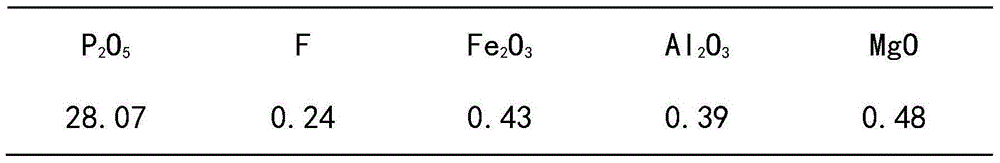

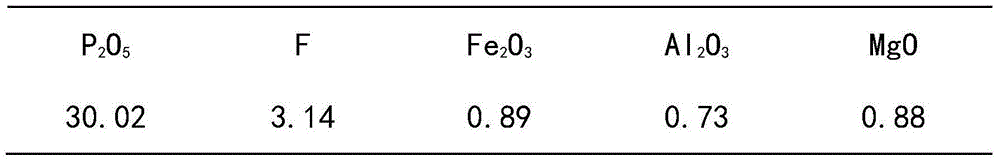

[0033] Step 1 Preparation of calcium dihydrogen phosphate slurry: natural phosphate rock is crushed and ball milled to obtain 80% raw ore pulp with a fineness of -200 mesh Taylor sieve, and the raw ore pulp is subjected to single reverse flotation to obtain a solid content of 60% concentrate pulp; Will P 2 o 5 Wet-process phosphoric acid with a concentration of 28.07% is added to the extraction tank, heated to a certain temperature, and the P 2 o 5 The concentrate slurry with a content of 30.02% is added to the extraction tank, the mass ratio of wet-process phosphoric acid to phosphoric acid concentrate is 5:1, the reaction temperature is 60°C, and the amount of cleaning agent is 1% of the mass of wet-process phosphoric acid. Get a mixed slurry. The mixed slurry is filtered through solid-liquid separation to obtain the filtrate A calcium dihydrogen phosphate solution and the reaction residue A, wherein the residue A can be returned to the dihydrate wet-process phosphoric ac...

Embodiment 2

[0047] Step 1 Preparation of calcium dihydrogen phosphate slurry: natural phosphate rock is crushed and ball milled to obtain 82% raw ore pulp with a fineness of -200 mesh Taylor sieve, and the raw ore pulp is obtained through flotation with a solid content of 75% concentrate pulp; the P 2 o 5 Wet-process phosphoric acid with a concentration of 49.88% is added to the extraction tank, heated to a certain temperature, and the P 2 o 5 The concentrate slurry with a content of 35.04% is added to the extraction tank, the mass ratio of wet-process phosphoric acid to phosphoric acid concentrate is 15:1, the reaction temperature is 95°C, and the amount of purifying agent is 4% of the mass of wet-process phosphoric acid. Get a mixed slurry. The mixed slurry is filtered through solid-liquid separation to obtain the filtrate A calcium dihydrogen phosphate solution and the reaction residue A, wherein the residue A can be returned to the dihydrate wet-process phosphoric acid system.

[0...

Embodiment 3

[0062] Step 1 Preparation of calcium dihydrogen phosphate slurry: natural phosphate rock is crushed and ball milled to obtain 83% raw ore pulp with a fineness of -200 mesh Taylor sieve, and the raw ore pulp is obtained through flotation with a solid content of 60% concentrate pulp; the P 2 o 5 Wet-process phosphoric acid with a concentration of 35.77% is added to the extraction tank, heated to a certain temperature, and the P 2 o 5 The concentrate slurry with a content of 33.66% is added to the extraction tank, the mass ratio of wet-process phosphoric acid to phosphoric acid concentrate is 7:1, the reaction temperature is 70°C, and the amount of cleaning agent is 2% of the mass of wet-process phosphoric acid. Get a mixed slurry. The mixed slurry is filtered through solid-liquid separation to obtain the filtrate A calcium dihydrogen phosphate solution and the reaction residue A, wherein the residue A can be returned to the dihydrate wet-process phosphoric acid system.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com