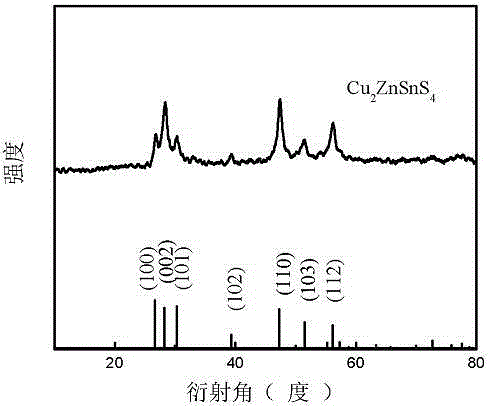

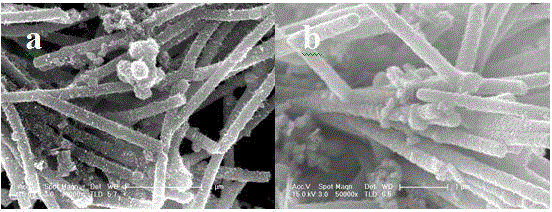

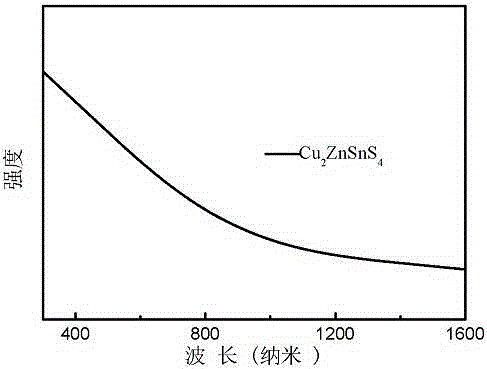

Preparation method for synthesizing super-long wurtzite structure Cu2ZnSnS4 nanorod in one step through solvothermal method

A solvothermal method and wurtzite technology, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problems of complicated operation, high cost, and increased operating coefficient of the film, and achieve simple preparation method and high synthesis temperature Low, excellent crystallinity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Weigh the reactant precursor 1mmol CuCl in the laboratory purification room 2 2H 2 O,0.5mmolZnCl 2 ,0.5mmolSnCl 4 ·5H 2 O,3.52mmolC 3 h 7 NO 2 Dissolve S in a mixed solution of 17ml ethylene glycol and 3ml oleylamine, add 0.1g oxalic acid and 0.05g hexadecyltrimethylammonium bromide, and then use magnetic stirring at room temperature until the solution is completely dissolved. Transfer to a 50 ml stainless steel autoclave lined with polytetrafluoroethylene and mix for three minutes. Afterwards, the reaction kettle was placed in a constant temperature heating box, reacted at 180° C. for 24 hours, cooled naturally to room temperature, and toluene and alcohol were added to the cooled reactant to cause the nanoparticles to settle. Then centrifuge at a speed of 80,000 rpm for 4 minutes, pour the suspension into a waste liquid bottle, and collect the lower sediment, which is the superlong wurtzite structure Cu 2 ZnSnS 4 Nano stave. After cleaning several times, put ...

Embodiment 2

[0017] Weigh the reactant precursor 1mmol CuCl in the laboratory purification room 2 2H 2 O,0.48mmolZnCl 2 ,0.48mmolSnCl 4 ·5H 2 O,3.5mmolC 3 h 7 NO 2 Dissolve S in a mixed solution of 17ml ethylene glycol and 3ml oleylamine, add 0.1g oxalic acid and 0.05g hexadecyltrimethylammonium bromide, and then use magnetic stirring at room temperature until the solution is completely dissolved. Transfer to a 50 ml stainless steel autoclave lined with polytetrafluoroethylene and mix for three minutes. Afterwards, the reaction kettle was placed in a constant temperature heating box, reacted at 180° C. for 24 hours, cooled naturally to room temperature, and toluene and alcohol were added to the cooled reactant to cause the nanoparticles to settle. Then centrifuge at a speed of 80,000 rpm for 4 minutes, pour the suspension into a waste liquid bottle, and collect the lower sediment, which is the superlong wurtzite structure Cu 2 ZnSnS 4 Nano stave. After cleaning several times, put...

Embodiment 3

[0019] Weigh the reactant precursor 1mmol CuCl in the laboratory purification room 2 2H 2 O,0.52mmolZnCl 2 ,0.52mmolSnCl 4 ·5H 2 O,3.54mmolC 3 h 7 NO 2Dissolve S in a mixed solution of 17ml ethylene glycol and 3ml oleylamine, add 0.1g oxalic acid and 0.05g hexadecyltrimethylammonium bromide, and then use magnetic stirring at room temperature until the solution is completely dissolved. Transfer to a 50 ml stainless steel autoclave lined with polytetrafluoroethylene and mix for three minutes. Afterwards, the reaction kettle was placed in a constant temperature heating box, reacted at 180° C. for 24 hours, cooled naturally to room temperature, and toluene and alcohol were added to the cooled reactant to cause the nanoparticles to settle. Then centrifuge at a speed of 80,000 rpm for 4 minutes, pour the suspension into a waste liquid bottle, and collect the lower sediment, which is the superlong wurtzite structure Cu 2 ZnSnS 4 Nano stave. After cleaning several times, put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com