Aspergillus niger gene knockout method

A gene knockout, Aspergillus niger technology, applied in the biological field, can solve the problems of time-consuming and laborious transformation of Aspergillus niger, and the bacteriostatic effect of 5-fluoroorotic acid is not obvious, so that the yield is not affected, the shape is normal, and the hygromycin Resistance removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The extraction of embodiment 1 Aspergillus niger genomic DNA

[0026] Inoculate Aspergillus niger spores into ME liquid medium (3% malt extract, 0.5% tryptone), culture at 250 r / min at 35°C for 48 hours, collect the balls with mirocloth, wash 3 times with sterile ultrapure water, and filter dry Moisture, quickly frozen in liquid nitrogen. The tissue was thoroughly ground by grinding with liquid nitrogen, and the filamentous fungal genome was extracted by QIAGEN DNeasyPlantMiniKit.

Embodiment 2

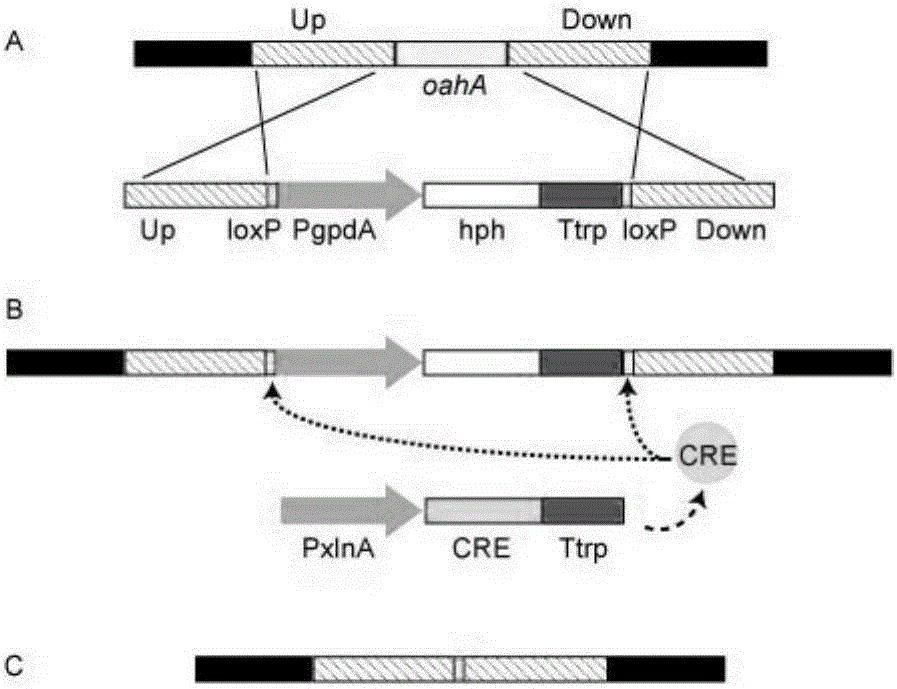

[0027] Example 2 Construction of cutting element and gene knockout expression cassette

[0028] 1) Construction of gene knockout expression cassette:

[0029] Using primer oahB5-F( GAGCTCGTTTAAAC TACCAAGGCCAGGCCGCAA) and oahB5-R ( GCGGCCGC CCGCCAGCAACCAATATTCAT) amplifies the fragment oahB5 of the upstream 2200bp of the oah gene from the Aspergillus niger genome, the 5' end of the fragment contains SacI and PmeI sites, and the 3' end of the fragment contains the NotI site; Utilize primer oahB3-F( ACTAGT ACAGAACACCCCTGATCGACAGT) and oahB3-R ( AAGCTT CCTGCTACAAATACATTGACCTC) amplifies the oahB3 fragment 2200bp downstream of the oah gene from the Aspergillus niger genome, and the two ends of the fragment contain SpeI and HindIII sites.

[0030] Primer PgpdB-F

[0031] ( GCGGCCGC ATAACTTCGTATAATGTATGCTATACGAAGTTATCCTTGTATCTCTACACACAGGCTCA) and hphB-R( ACTAGT CCGCGGTCGGCATCTACT) amplifies the complete gpdA promoter and hph half fragment from the pAN7-1 vector, named hph...

Embodiment 3

[0036] Preparation and transformation of embodiment 3 Aspergillus niger protoplast

[0037] Press 3×10 5 Inoculate the spores to ME liquid medium at a concentration of / ml, and culture overnight at 30°C and 200r / min. Collect mycospheres with mirocloth, and wash mycospheres with sterile water. A certain amount of lysozyme was weighed, dissolved with osmotic pressure stabilizer KMC, and sterilized by filtration with a sterile filter membrane. Weigh a certain amount of bacterial spheres, add them to the enzymatic hydrolysis solution, incubate with shaking at 37°C 100r / min for about 3 hours until the mycelium is completely digested into protoplasts, centrifuge at 1000rpm at 4°C for 10min, discard the supernatant, add the same volume of pre-cooled STC, Centrifuge at 1000 rpm at 4°C for 10 min, discard the supernatant, wash twice, add 100 μL STC, and mix well. Add 10 μL of linearized nucleic acid fragments and 330 μL PEG buffer to 100 μL of Aspergillus niger protoplasts, place on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com