Method for synthesizing CdSe/P3HT composite nanocrystals by direct growth method

A nanocrystalline, direct technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of harsh reaction conditions, high preparation cost, high reaction temperature, and achieve lower reaction temperature, good thermal stability, and alignment. neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of method of direct growth method synthetic CdSe / P3HT composite nanocrystal, comprises the following steps:

[0021] 1) Pour 6g of polymer P3HT, 79g of Se powder, 340g of cadmium stearate, 1L of trichlorobenzene, and 15L of ODE into the reaction kettle, stir well, and react at 140°C for 25h;

[0022] 2) Cool, add acetone to wash, precipitate, centrifuge, and centrifuge at 3000r for 5-10 minutes, discard the supernatant, dissolve the precipitate with excess n-hexane, wash and dry to obtain the CdSe / P3HT composite nanocrystals.

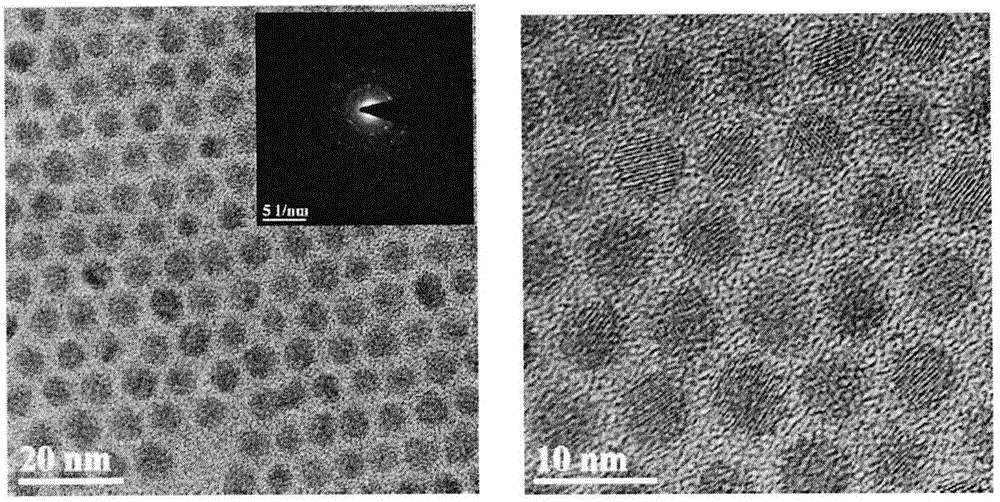

[0023] The size of CdSe superstructure hybrid nanocrystals is about 20nm on average.

Embodiment 2

[0025] A kind of method of direct growth method synthetic CdSe / P3HT composite nanocrystal, comprises the following steps:

[0026] 1) Pour 6g of polymer P3HT, 395g of Se powder, 340g of cadmium stearate, 1L of trichlorobenzene, and 15L of ODE into the reaction kettle and stir well, and react at 180°C for 15 h ;

[0027] 2) Cool, add acetone to wash, precipitate, centrifuge, and centrifuge at 3000r for 5-10 minutes, discard the supernatant, dissolve the precipitate with excess n-hexane, wash and dry to obtain the CdSe / P3HT composite nanocrystals.

[0028] The size of CdSe superstructure hybrid nanocrystals is 5.3nm on average.

Embodiment 3

[0030] A kind of method of direct growth method synthetic CdSe / P3HT composite nanocrystal, comprises the following steps:

[0031] 1) Pour 6g of polymer P3HT, 395g of Se powder, 680g of cadmium stearate, 1L of trichlorobenzene, and 15L of ODE into the reaction kettle, stir well, and react at 240°C for 5h;

[0032] 2) Cool, add acetone to wash, precipitate, centrifuge, and centrifuge at 3000r for 5-10 minutes, discard the supernatant, dissolve the precipitate with excess n-hexane, wash and dry to obtain the CdSe / P3HT composite nanocrystals.

[0033] The size of CdSe superstructure hybrid nanocrystals is about 5nm on average.

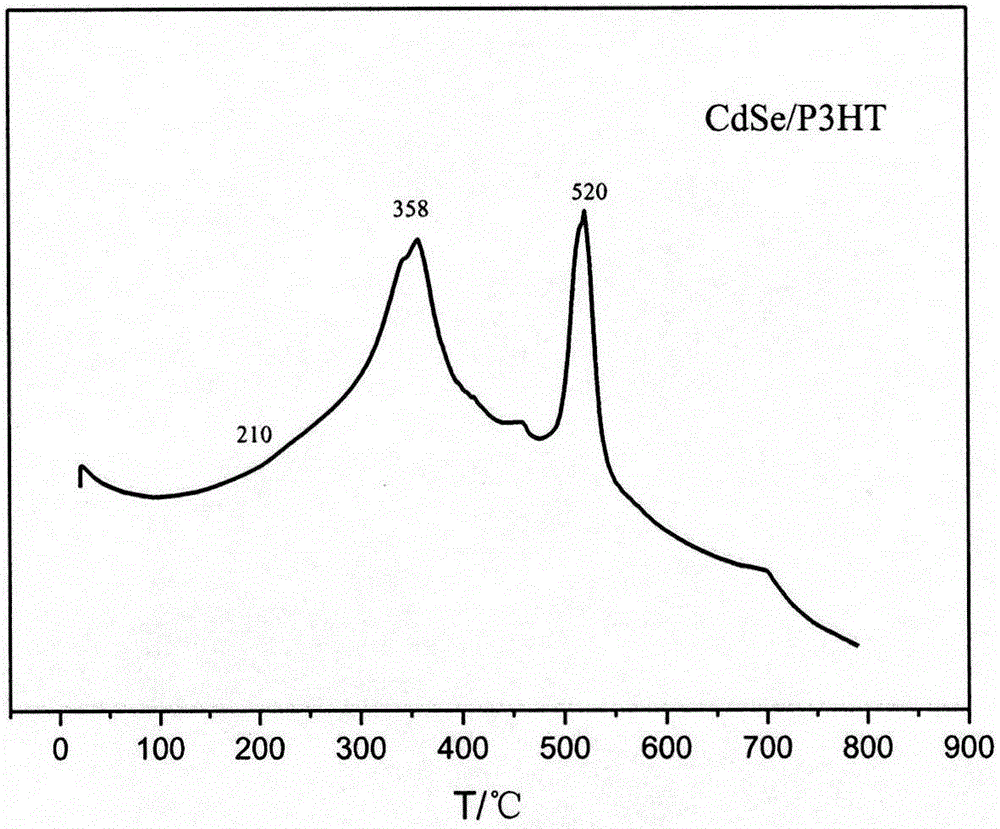

[0034] figure 1 is the DSC curve of CdSe / P3HT, by figure 1 It can be seen that the decomposition process of CdSe / P3HT includes two exothermic peaks, the first exothermic peak begins to increase at 210 °C, the heat flow rate increases, the exothermic speed increases, and the released heat increases, reaching the maximum at 358 °C. The second exothermic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com