Manufacturing method for minuteness spherical titanium powder

A manufacturing method and powder technology are applied in the manufacturing field of fine spherical titanium powder, which can solve the problems of not meeting the requirements of injection molding process, increasing hydrogenation, crushing, dehydrogenation, and reducing the particle size of fine titanium powder, and achieving low oxygen content. , The effect of improving uniformity and reducing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

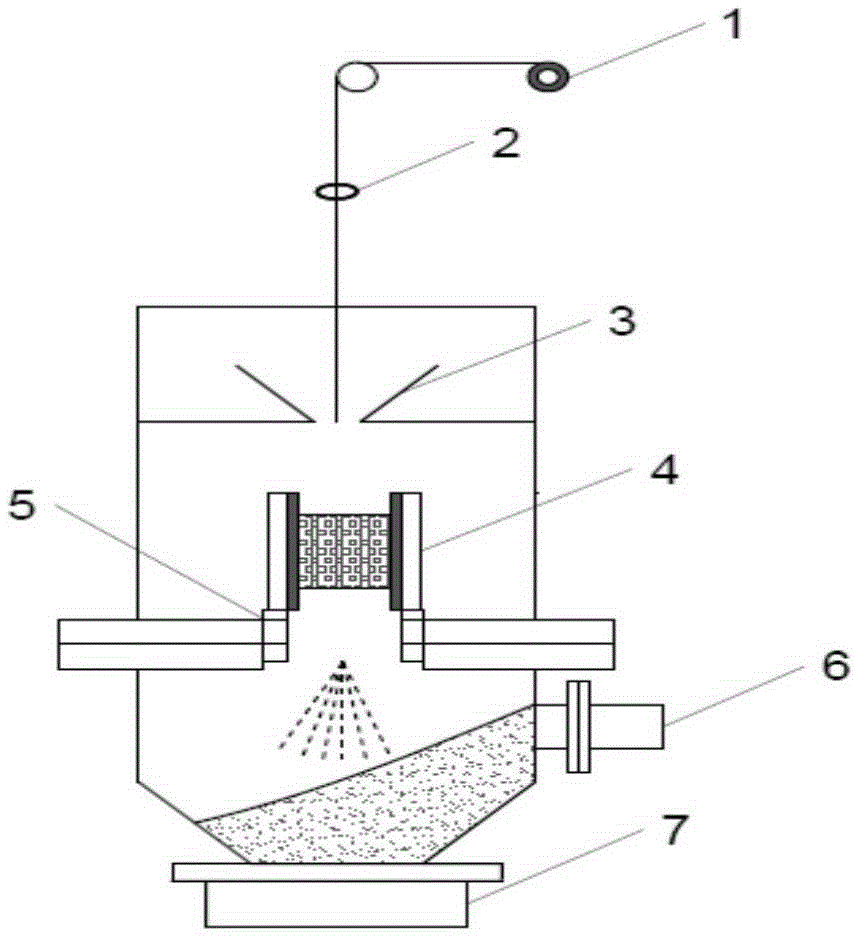

[0023] Using titanium sponge as raw material, it is made into rods or wires, which are sent into the melting chamber through a continuous feeder. The raw material feeding rate is 0.2kg / min, and it is induced by double femtosecond pulsed laser with a pulse interval of 2ns. The pulse width is 10fs, the laser is focused in the air and breaks down the air to generate plasma, and the titanium sponge rod or wire is heated and melted under the action of the plasma. The melt flow is poured into the tundish of the atomization powder making equipment, and then transferred into the atomization chamber through the guide tube, and the inner diameter of the guide tube is 4mm. Vacuumize the atomization chamber and melting chamber, and the vacuum degree reaches 1×10 -4 Pa. Then the titanium melt flows through the centrifugal nozzle at a certain flow rate, and the thin liquid layer is crushed under the action of ultrasonic vibration, and the small liquid droplets aroused splash out from the w...

Embodiment 2

[0026]Using titanium sponge as raw material, it is made into rods or wires, which are sent into the melting chamber through a continuous feeder. With a width of 100fs, the laser is focused in the air to break down the air to generate plasma, and the titanium sponge rod or wire is heated and melted under the action of the plasma. The melt flow is poured into the tundish of the atomization powder making equipment, and then transferred into the atomization chamber through the guide tube, and the inner diameter of the guide tube is 5mm. Vacuumize the atomization chamber and melting chamber, and the vacuum degree reaches 1×10 -2 Pa. Then the titanium melt flows through the centrifugal nozzle at a certain flow rate, and the thin liquid layer is crushed under the action of ultrasonic vibration, and the aroused small droplets splash out from the wave crest to form mist, realizing primary atomization. The second layer of the nozzle adopts the Laval nozzle structure. After the primary...

Embodiment 3

[0029] Using titanium sponge as raw material, it is made into rods or wires, which are sent into the melting chamber through a continuous feeder. The raw material feeding rate is 1.5kg / min, and it is induced by double femtosecond pulsed laser with a pulse interval of 4ns. The pulse width is 100fs, the laser is focused in the air and breaks down the air to generate plasma, and the titanium sponge rod or wire is heated and melted under the action of the plasma. The melt flow is poured into the tundish of the atomization powder making equipment, and then transferred into the atomization chamber through the guide tube, and the inner diameter of the guide tube is 4mm. Vacuumize the atomization chamber and melting chamber, and the vacuum degree reaches 1×10 -3 Pa. Then the titanium melt flows through the centrifugal nozzle at a certain flow rate, and the thin liquid layer is crushed under the action of ultrasonic vibration, and the aroused small droplets splash out from the wave cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com