A three-dimensional porous microfluidic chip and its preparation method and application

A microfluidic chip, three-dimensional porous technology, applied in the fields of biology, chemistry and material science, can solve the problems of high price, cumbersome steps, limited application, etc., and achieve the effects of low cost, good repeatability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

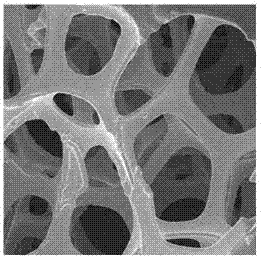

[0045] (1) The nickel foam (0.5mm×4mm×20mm) was ultrasonically cleaned with acetone, ethanol and ultrapure water for 30 minutes, and then dried in an oven. figure 1 A scanning electron micrograph of nickel foam, showing its three-dimensional porous structure.

[0046] (2) Immerse the dried nickel foam into a 2mL centrifuge tube filled with uncrosslinked PDMS (polydimethylsiloxane) liquid, and centrifuge at 8000rpm for 5 minutes to fully infiltrate the nickel foam with PDMS.

[0047] (3) Transfer the PDMS-impregnated nickel foam obtained in step (2) to an empty 2mL centrifuge tube, centrifuge at 3000rpm for 3 minutes to remove the PDMS in the pores of the nickel foam, and then heat in an oven at 80°C for 3 hours to solidify the PDMS.

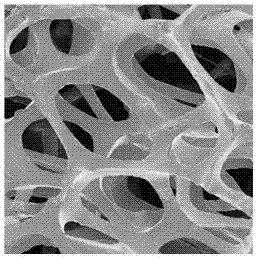

[0048] (4) Immerse the PDMS-coated nickel foam obtained in step (3) in a 7mol / L nitric acid solution, etch for 1 hour to remove the nickel template, and then wash off the residual nitric acid solution with ultrapure water to obtain a three-dimens...

Embodiment 2

[0057] (1) The nickel foam (1.2mm×4mm×20mm) was ultrasonically cleaned with acetone, ethanol and ultrapure water for 30 minutes, and then dried in an oven.

[0058] (2) Immerse the dried nickel foam into a 2mL centrifuge tube filled with uncrosslinked PDMS liquid, and centrifuge at 6000rpm for 3 minutes to fully infiltrate the nickel foam with PDMS.

[0059] (3) Transfer the PDMS-impregnated nickel foam obtained in step (2) to an empty 2mL centrifuge tube, centrifuge at 3000rpm for 3 minutes to remove excess PDMS in the pores of the nickel foam, and then heat in an oven at 75°C for 4 hours to solidify the PDMS.

[0060] (4) Immerse the PDMS-coated nickel foam obtained in step (3) in a 14mol / L nitric acid solution, etch for 5 hours to remove the nickel template, and then wash off the residual nitric acid solution with ultrapure water to obtain a three-dimensional porous material.

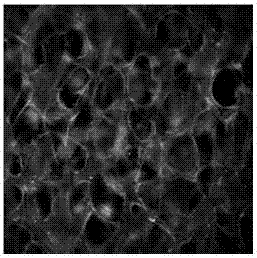

[0061] (5) Immediately immerse the obtained three-dimensional porous material Plasma in phosphat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com