Beneficiation method for low-grade copper sulphide ore

A technology of copper sulfide ore and ore dressing method, which is applied in flotation, solid separation, etc., can solve the problems of difficulty in guaranteeing the copper recovery rate of copper concentrate products, difficult recovery, and surface pollution, so as to optimize the environment of flotation pulp and avoid rich The effect of collecting and crushing and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

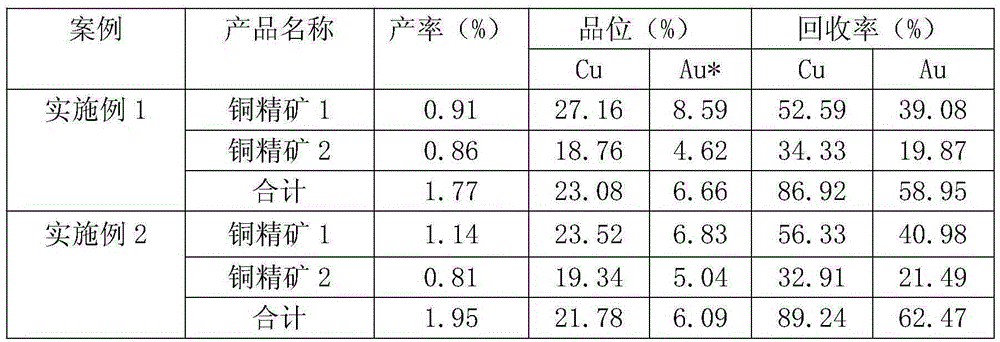

[0042] The copper ore used is arsenic-containing low-copper primary copper sulfide ore, and its chemical composition (wt%) is as follows: copper 0.48%, sulfur 4.38%, gold 0.19g / t, silver 5.2g / t. The copper phase analysis is as follows: secondary copper sulfide accounts for 69.29%, primary copper sulfide accounts for 18.10%, and copper oxide accounts for 12.61%.

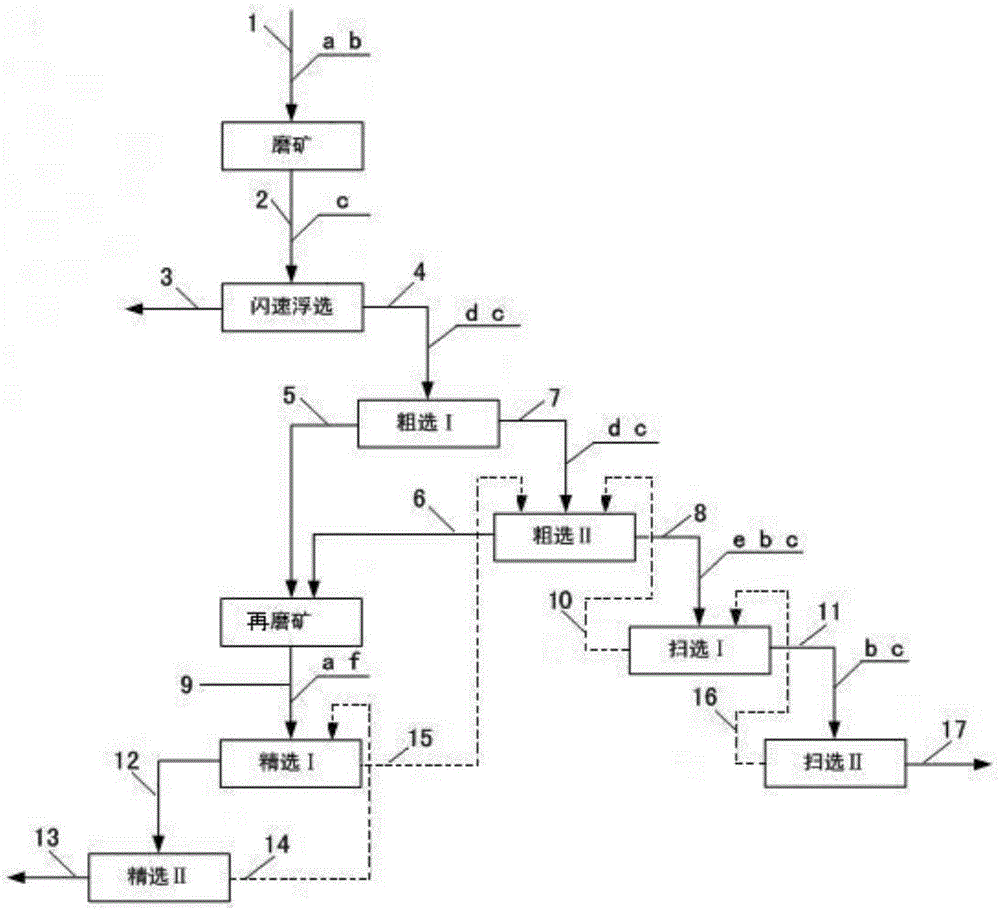

[0043]According to the dry weight of each ton of raw ore, firstly, the raw ore 1 is sequentially added with 1000g of adjusting agent lime a and 5g of ammonium butyl ammonium black medicine, and the ore is ground by a ball mill until the fineness of the ore is -0.074mm, which accounts for 55.0% of the ore powder A2, and the pH is adjusted to 8. Add foaming agent MIBCc10g, and obtain copper concentrate A3 and flash flotation tailings 4 through flash flotation; flash flotation tailings 4 undergo roughing I operation and roughing II operation to obtain roughing I concentrate 5. Roughing II concentrate 6 and roughing I tai...

Embodiment 2

[0044] Example 2: According to the dry weight of each ton of raw ore, firstly, the raw ore is sequentially added with an adjustment agent lime dosage of 1500g / t and a butylammonium black drug dosage of 6g / t, and the ore is ground by a ball mill until the grinding fineness is -0.074mm, accounting for 60.0 %, ball mill discharge (pH = 9), add foaming agent MIBCc dosage 20g / t, and obtain copper concentrate A3 and flash flotation tailings 4 through flash flotation operation; flash flotation tailings 4 are roughed Ⅰ operation and roughing II operation to obtain roughing I concentrate 5, roughing II concentrate 6, roughing I tailings 7, roughing II tailings 8; roughing II tailings 8 after sweeping I operation and sweeping Operation II results in scavenging I concentrate 10, sweeping II concentrate 16, sweeping I tailings 11, and final tailings 17; roughing I concentrates and roughing II concentrates are combined into a ball mill for regrinding to fine ore After the concentration is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com