Tomato composite fertilizer and production method thereof

A compound fertilizer and tomato technology, which is applied to fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of little improvement of soil quality in tomato plots, no inhibition or prevention of root-knot nematodes, and no magnetization of fertilizers. It is suitable for process production, shortening fermentation time and loosening soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

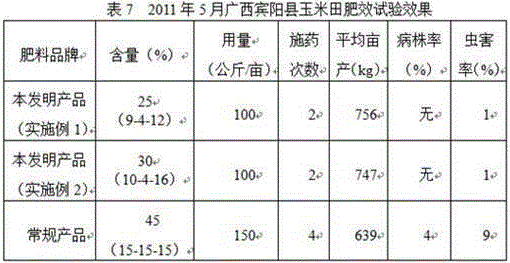

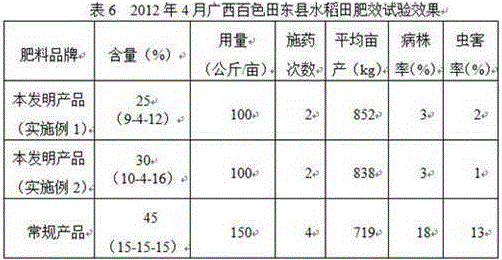

[0049] Prepare tomato compound fertilizer (9-4-12) with 25% of total nitrogen, phosphorus and potassium nutrients (9-4-12) and 20% of organic matter in the organic fertilizer (9-4-12), respectively referring to N, P 2 o 5 、K 2 The nutrient percentage content of O, the same below).

[0050] Raw material formula ratio: 170 kg of urea (calculated as 46.0% containing N), 85 kg of diammonium phosphate (calculated as 16% containing N, containing P 2 o 5 According to 46.0%, 5 kg of calcium magnesium phosphate fertilizer (including P 2 o 5 18.0%, 9% Mg, 28.4% Ca, 12.7% Si), 240 kg potassium sulfate (K 2 O is calculated as 50.0%, and S is calculated as 17.0%) (including K 2 O based on 60.0%), borax 1 kg (containing B based on 11%), zinc sulfate heptahydrate 0.5 kg (containing Zn based on 23%), ammonium molybdate 0.5 kg (containing Mo based on 54%), copper sulfate 0.5 kg (calculated as 23% containing Cu), 100 kg of amino acid, 200 kg of organic fertilizer (including 20 kg of mola...

Embodiment 2

[0057] Prepare tomato compound fertilizer with 30% of total NPK nutrients (10-4-16) and 20% of organic matter (10-4-16 refers to N, P 2 o 5 、K 2 The nutrient percentage content of O, the same below).

[0058] Raw material formula ratio: 190 kg of urea (calculated as 46.0% containing N), 85 kg of diammonium phosphate (calculated as 16% containing N, containing P 2 o 5 According to 46.0%, 5 kg of calcium magnesium phosphate fertilizer (including P 2 o 5 18.0%, 9% for Mg, 28.4% for Ca, 12.7% for Si), 320 kg of potassium sulfate (containing K 2 O is 50.0%, S is 17.0%, borax is 1 kg (B is 11%), zinc sulfate heptahydrate is 0.5 kg (Zn is 23%), ammonium molybdate is 0.5 kg (Mo is 54 %), 0.5 kg of copper sulfate (calculated as 23% of Cu), 50 kg of amino acid, 200 kg of organic fertilizer (including 30 kg of molasses alcohol waste liquid), 100 kg of chitin, and 52.5 kg of pyrite ash.

[0059] Organic fertilizer is a product obtained by fermenting molasses alcohol waste liquid, s...

Embodiment 3

[0065] Prepare tomato compound fertilizer with 35% of total NPK nutrients (13-5-17) and 20% of organic matter (13-5-17 refers to N, P 2 o 5 、K 2 The nutrient percentage content of O, the same below).

[0066] Raw material formula ratio: 250 kg of urea (calculated as 46.0% containing N), 105 kg of diammonium phosphate (calculated as 16% containing N, containing P 2 o 5 According to 46.0%, 5 kg of calcium magnesium phosphate fertilizer (including P 2 o 5 18.0%, 9% for Mg, 28.4% for Ca, 12.7% for Si), 340 kg of potassium sulfate (containing K 2 O is 50.0%, S is 17.0%, borax is 1 kg (B is 11%), zinc sulfate heptahydrate is 0.5 kg (Zn is 23%), ammonium molybdate is 0.5 kg (Mo is 54 %), 0.5 kg of copper sulfate (calculated as 23% of Cu), 50 kg of amino acid, 200 kg of organic fertilizer (including 25 kg of molasses alcohol waste liquid), 20 kg of chitin, and 27.5 kg of pyrite ash.

[0067] Organic fertilizer is a product obtained by fermenting molasses alcohol waste liquid, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com