A kind of synthesis technique of 3-hydroxy-2-nitropyridine

A technology of nitropyridine and hydroxypyridine, applied in the field of synthesis technology of 3-hydroxy-2-nitropyridine, can solve the problems of low yield, excessive use of strong acid, etc., and achieves improved reaction yield, improved yield, The effect of shortening the post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

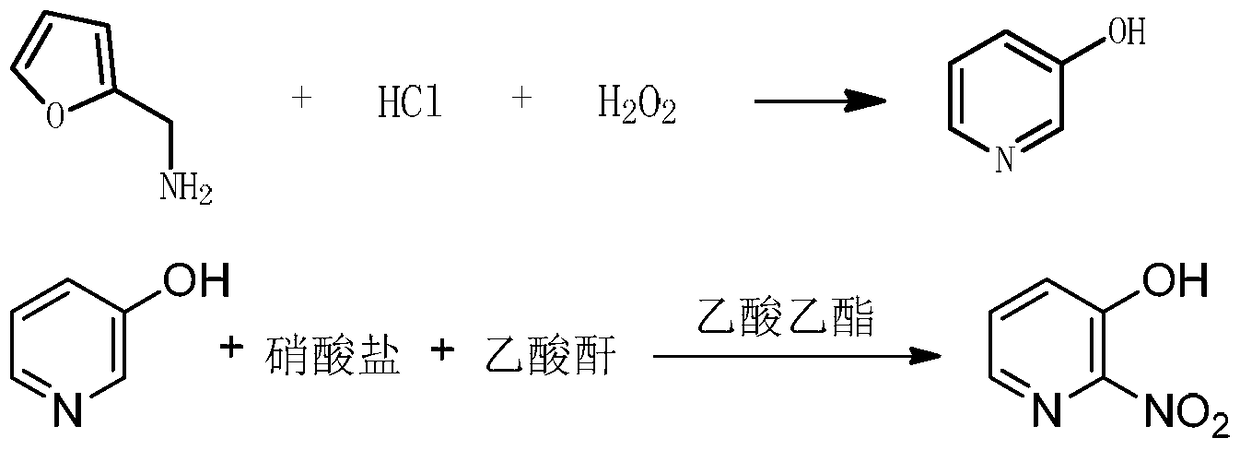

[0033] Example 1: Preparation of 3-hydroxypyridine.

[0034] A thermometer, a reflux condenser, a constant pressure dropping funnel, and a magnetically stirred 250ml three-necked flask were added with 85ml of 20% hydrochloric acid solution (0.510mol), and then slowly added dropwise 10g of furfurylamine (0.102mol). After the addition is completed, cool to between 10°C and slowly add 19ml of 30% concentration of H 2 o 2 , the dropping time is 30-40 minutes. After the dropping, the holding time is 1.5 hours, heated to 100°C, heated to reflux for 2.5-3 hours, spotting the sample to monitor the reaction end point, cooling to room temperature after the reaction, and using 1mol / L NaOH The pH was adjusted to 7-8, and 8.1 g of 3-hydroxypyridine was obtained by repeated extraction with ether, with a yield of 83%.

[0035] Replacement example 1-1-1-9:

[0036] The preparation method is the same as in Example 1, except that the concentration of hydrochloric acid is adjusted, the temper...

Embodiment 2

[0040] Example 2: Preparation of 3-hydroxy-2-nitropyridine.

[0041] 10g of 3-hydroxypyridine (105mmol) and 80ml of ethyl acetate and 4.2g of KNO 3 (42mmol) and 21ml of acetic anhydride (0.210mol) were added to a 250mL three-neck flask, heated at a temperature of 45°C with magnetic stirring to react, and the sample was monitored to monitor the end of the reaction. Wash the ester 1-2 times, take the filtrate and adjust the pH to neutral with NaOH saturated solution, extract 3-4 times with ethyl acetate, take the extract and add activated carbon and heat it under reflux for 1 hour, cool and filter, take the filtrate with anhydrous magnesium sulfate Dry, filter, concentrate on a rotary evaporator, and dry in a drying oven. 11.9 g of 3-hydroxy-2-nitropyridine was obtained with a yield of 81%.

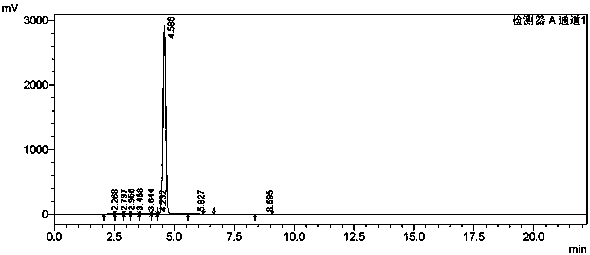

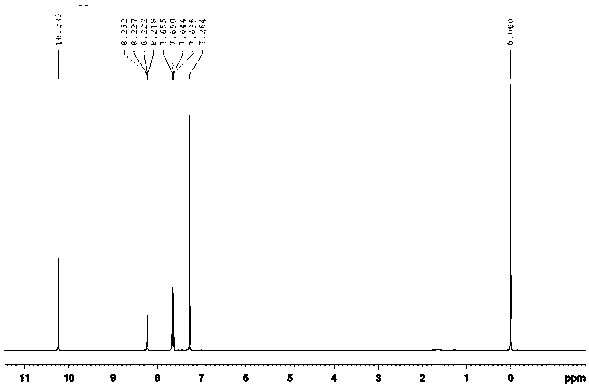

[0042]The nuclear magnetic resonance spectrum and high performance liquid chromatography of the product are as follows: figure 1 , figure 2 shown.

[0043] Replacement examples 2-1 to...

Embodiment 3

[0048] Example 3: Preparation of 3-hydroxy-2-nitropyridine.

[0049] 50g of 3-hydroxypyridine (0.525mol) and 400ml of ethyl acetate and 74g of KNO 3 (0.735mol) and 367ml of acetic anhydride (3.675mol) were added to a 1L three-neck flask, heated and stirred mechanically at a temperature of 45°C to react, and the sample was monitored to monitor the end of the reaction. Wash 1-2 times with ethyl ester, take the filtrate and adjust the pH to neutral with NaOH saturated solution, extract 3-4 times with ethyl acetate, take the extract and add activated carbon to reflux for 1 hour, cool and filter, take the filtrate with anhydrous sulfuric acid Magnesium was dried, filtered, concentrated on a rotary evaporator, and then dried in a drying oven. 66 g of 3-hydroxy-2-nitropyridine was obtained with a yield of 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com