Method for removing phosphorus from wastewater by utilizing coal ash

A waste water and coal powder ash technology, applied in the environmental field, can solve the problems of large chemical consumption, difficult treatment, high cost of phosphorus removal, etc., and achieve good chemical adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 (Example 1 is used to illustrate that the method provided by the invention is also applicable to inorganic phosphorus.)

[0034] (1) Take 200 mL of simulated wastewater prepared with sodium dihydrogen phosphate at a concentration of 5000 mg / L (calculated as P) into a 250 mL Erlenmeyer flask, and adjust the pH of the wastewater to 6.0 with 2 mol / L hydrochloric acid.

[0035] (2) Add quantitatively 30g of coal powder ash with a calcium oxide content of 25%, the mass ratio of coal powder ash to waste water is 3:20, and react at a constant temperature of 55°C for 1 hour under magnetic stirring (300 rpm).

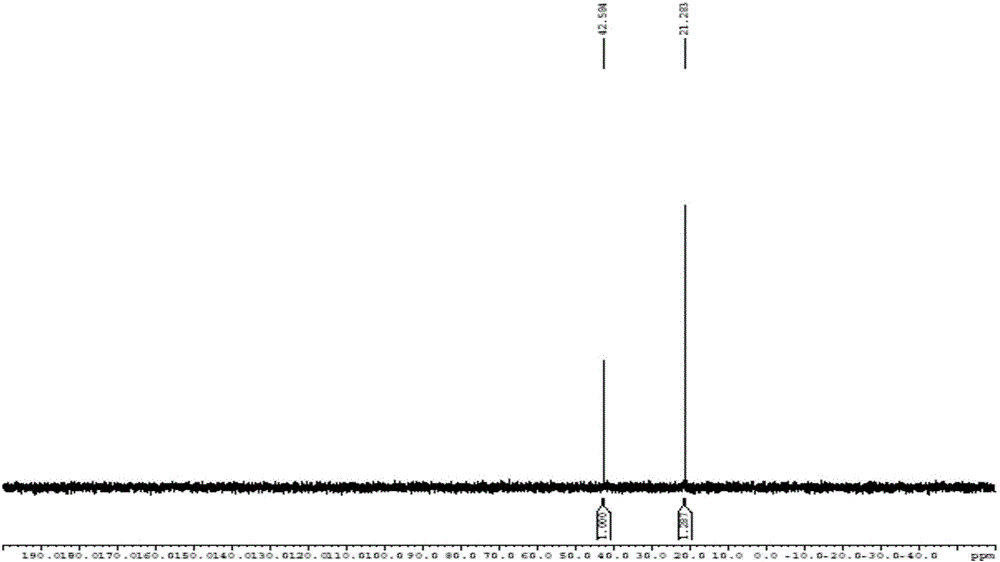

[0036] (3) Separation of waste water and coal dust after the reaction. Filter with WhatmanNo1# filter paper, adopt plasma emission spectrometry (ICP) and pH meter to test the total phosphorus and pH value in the filtrate, and its total phosphorus content is 51mg / L, and pH is 12.29. Phosphorus removal efficiency reaches 99.0%. The experimental results show that...

Embodiment 2

[0038] (1) Take 200 mL of simulated wastewater prepared with methylphosphonic acid at a concentration of 2155 mg / L (calculated as P) into a 250 mL Erlenmeyer flask, and adjust the pH of the wastewater to 6.8 with 20% sodium hydroxide.

[0039] (2) Add quantitatively 15g of coal powder ash with a calcium oxide content of 25%, the mass ratio of coal powder ash to wastewater is 3:40, and react at a constant temperature of 55°C for 1 hour under magnetic stirring (300 rpm).

[0040] (3) Separation of waste water and coal dust after the reaction. Filter with WhatmanNo1# filter paper, adopt plasma emission spectrometry (ICP) and pH meter to test the total phosphorus and pH value in the filtrate, and its total phosphorus content is 93mg / L, and pH is 12.08. Phosphorus removal efficiency reaches 95.7%. The experimental results show that coal fly ash not only has a strong chemical adsorption effect on orthophosphorus, but also has a strong removal effect on organic phosphorus.

Embodiment 3

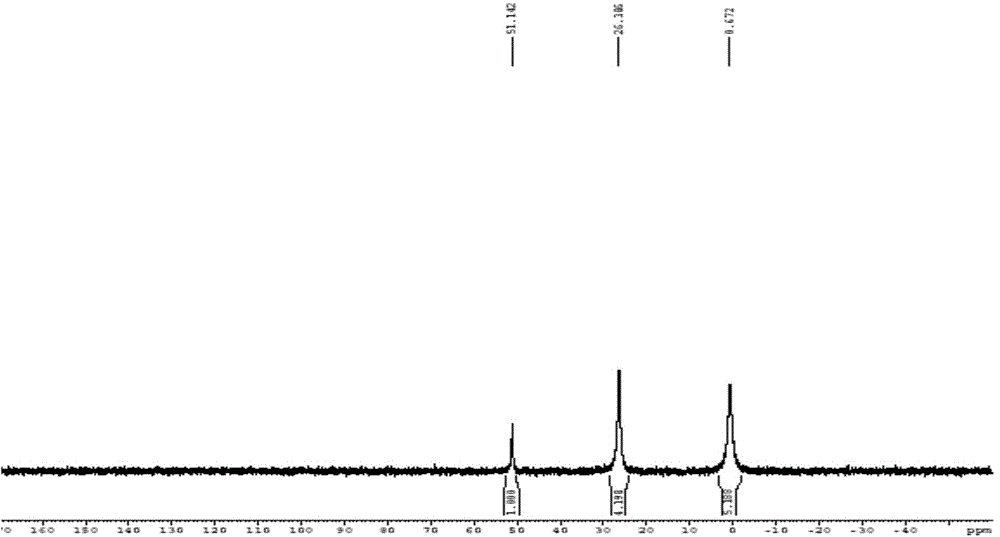

[0042] Get industrial waste water, through ion chromatographic analysis, total phosphorus (calculated as P) in water is 155mg / L, wherein contains 63.3% orthophosphorus, 36.7% organic phosphorus. The organic phosphorus content in the form of methylphosphonic acid is 43.5mg / L (accounting for 76.5% of organic phosphorus), and the content of organic phosphorus in the form of dimethylphosphonic acid is 13.4mg / L (accounting for 23.5% of total organic phosphorus).

[0043] (1) Take the above-mentioned 200mL industrial wastewater into a 250mL Erlenmeyer flask, and adjust the pH of the wastewater to 6.5 with 20% sodium hydroxide.

[0044] (2) Add quantitatively 7.5g of coal powder ash with a calcium oxide content of 25%, the mass ratio of coal powder ash to waste water is 3:80, and react at a constant temperature of 55°C for 1 hour under magnetic stirring (300 rpm).

[0045] (3) Separation of waste water and coal dust after the reaction. Filter with WhatmanNo1# filter paper, use plasma ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com