Method for nathphalene alkylation

A technology of decalinyl and decalinyl, which is applied in the field of decalinylation and can solve the problems of easy deactivation of catalysts, low type selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

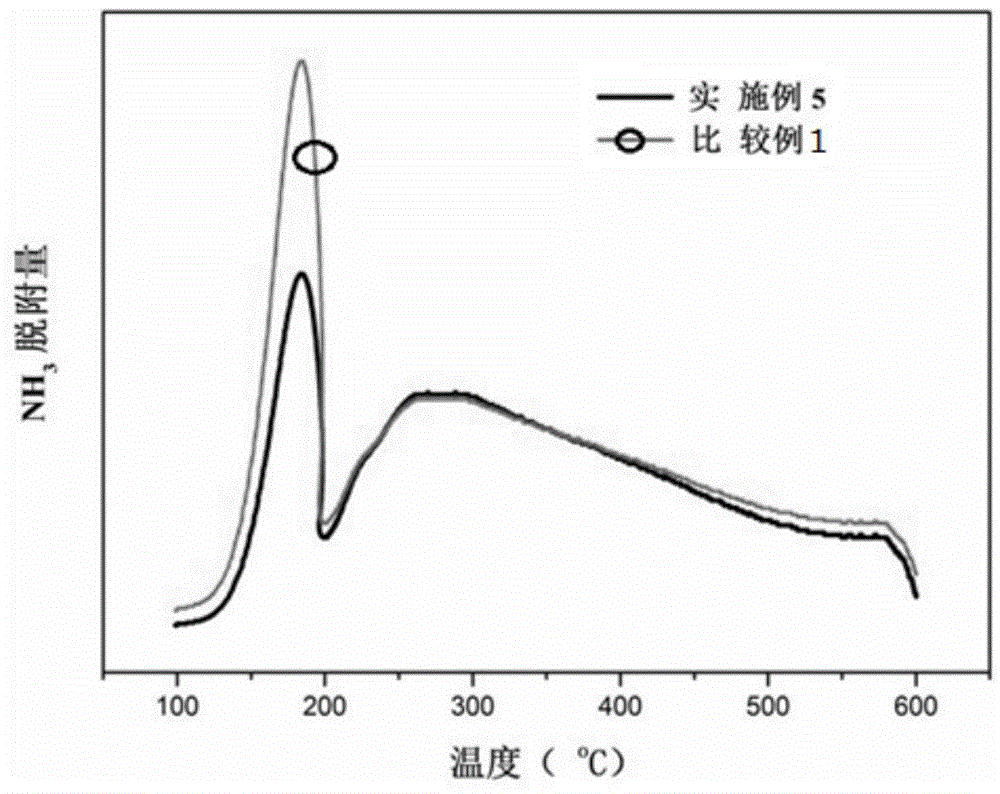

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Take 50g water glass (SiO2 Content is 27.20wt%, modulus is 3.2), 0.85g aluminum sulfate, 96wt% sodium hydroxide 1.0g, deionized water 50g, 70wt% ethylamine aqueous solution 50g, ZSM-5 crystal seed 0.5g, mix to form The gel was left to stand for 6 hours, and then crystallized at 170°C for 14 hours. A white solid was obtained by filtration, and the solid was repeatedly washed with deionized water until the pH test paper was tested to be neutral. Drying gave 10.3 g of uncalcined powder. It is ZSM-5 zeolite by X-ray powder diffraction analysis.

[0028] (2) Take 10.3g of the powder obtained in the previous step, and use 1mol / L Mg(NO 3 ) 2 The 200ml solution was exchanged three times at room temperature, each time for 8 hours.

[0029] (3) Take the solid exchanged in the previous step, dry it, and roast it at 550° C. for 6 hours, and shape it to obtain a finished catalyst.

[0030] (4) The evaluation of the alkylation reaction of naphthalene and propylene was perfor...

Embodiment 2

[0033] (1) 600 grams of 40% silica sol, 38.9 grams of sodium aluminate (42% alumina content), 70.6 grams of 25% tetraethylammonium hydroxide (TEAOH), 5.0 grams of diethylamine (DEA), 168.0 grams of tetraethylammonium hydroxide Ethylammonium bromide (TEABr), 16.0 grams of sodium hydroxide, 136.0 grams of 25% ammonium hydroxide and 925.1 grams of water were mixed and stirred evenly at room temperature. Then, it was transferred to a stainless steel autoclave with a crystallization temperature of 140° C. and reacted for 96 hours. After the reaction, the crystalline product was filtered, washed with deionized water, and dried. According to X-ray powder diffraction analysis, it is zeolite beta with BEA structure.

[0034] (2) Take 200g of the powder obtained in the previous step, and use 1mol / L of Mg(NO 3 ) 2 The solution was exchanged three times at 80°C with 2000ml of solution, each time for 8 hours.

[0035] (3) Take the solid exchanged in the previous step, dry it, and roast...

Embodiment 3

[0039] (1) Get aluminum tert-butoxide (wt97%) 5g, diethyldimethylammonium hydroxide (wt20%) 160g, sodium hydroxide 8g mix, then add 160gTEOS (wt98%) and 140g deionized water wherein, Stir well at room temperature. Then it was transferred to a 1L stainless steel crystallization kettle, and stirred and crystallized at 150°C for 96 hours. After the crystallization reaction is completed, filter, wash the crystalline product with deionized water, and dry. According to X-ray powder diffraction analysis, it is UZM-8 zeolite with layered structure.

[0040] (2) Take 35 g of the powder obtained in the previous step, and exchange it with 500 ml of 2 mol / L magnesium chloride solution at 80° C. for three times, each time for 8 hours.

[0041] (3) Take the solid exchanged in the previous step, dry it, and roast it at 550° C. for 6 hours, and shape it to obtain a finished catalyst.

[0042] (4) Carry out the isomerization reaction of diisopropylnaphthalene on a 100ml reactor device, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com