Method for recovering chloromethane from acid methanol tail gas

A tail gas recovery and methyl chloride technology, which is applied in chemical recovery, chemical instruments and methods, climate sustainability, etc., can solve the problems of reduced catalyst activity and poor stability, so as to prolong catalyst life, improve reaction selectivity, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

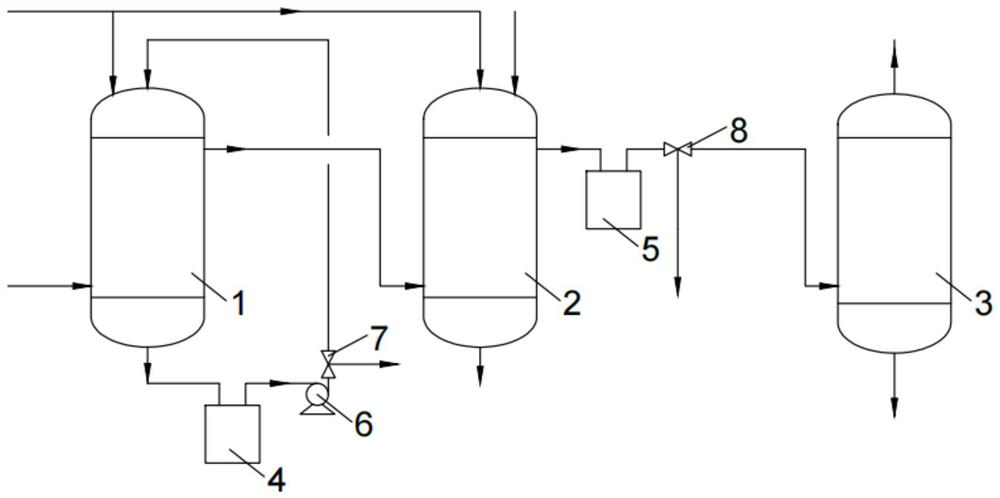

Image

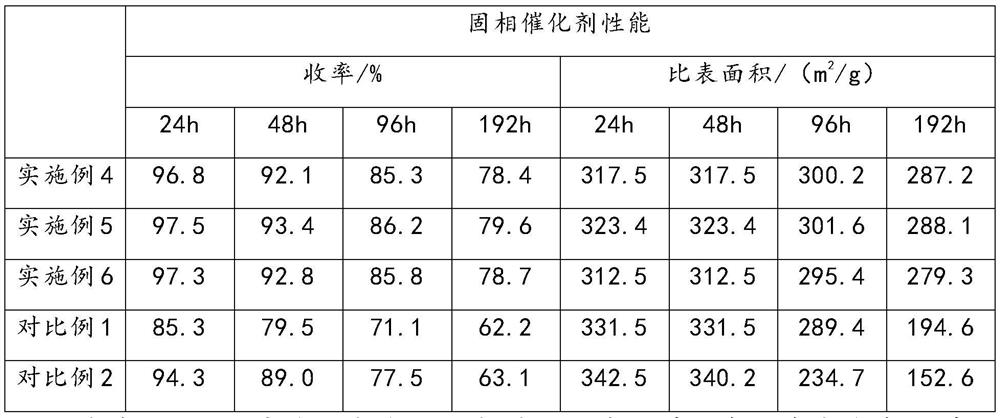

Examples

Embodiment 1

[0033] The preparation method of solid-phase catalyst comprises the following steps:

[0034] (1) Preparation of ZSM-5: add 100g of sodium silicate, 1g of sodium metaaluminate, and 10,000mL of deionized water into the reactor, stir evenly, add 30g of tetrapropylammonium bromide, stir evenly, add sulfuric acid to adjust pH , heated to 150°C, hydrothermally crystallized for 48h, washed with water, dried, and calcined in a muffle furnace to obtain ZSM-5;

[0035] (2) Preparation of modified ZSM-5: 65mL of N,N-dimethylformamide, 10g of ZSM-5, 8g of 2-bromopropionic acid, and 600mL of dichloromethane were added to the reactor, stirred mechanically, and reacted at room temperature for 12h, Filter under reduced pressure, wash and dry to obtain modified ZSM-5;

[0036](3) prepare phosphorus-modified ZSM-5: 4g triphenylphosphine, 10g toluene are added in the reactor, mechanical stirring is dissolved, and 0.7g potassium iodide aqueous solution, 10g modified ZSM-5 are added, and the pot...

Embodiment 2

[0039] The preparation method of solid-phase catalyst comprises the following steps:

[0040] (1) Preparation of ZSM-5: add 100g sodium silicate, 25g sodium metaaluminate, and 15000mL deionized water to the reaction kettle, stir mechanically, add 45g tetrapropylammonium bromide, stir mechanically, add sulfuric acid to adjust pH , heated to 165°C, hydrothermally crystallized for 60h, washed with water, dried, and calcined in a muffle furnace to obtain ZSM-5;

[0041] (2) Preparation of modified ZSM-5: 85mL of N,N-dimethylformamide, 10g of ZSM-5, 9g of 2-bromopropionic acid, and 1000mL of dichloromethane were added to the reactor, stirred mechanically, and reacted at room temperature for 15h, Filter under reduced pressure, wash and dry to obtain modified ZSM-5;

[0042] (3) prepare phosphorus-modified ZSM-5: 5.5g triphenylphosphine, 14g toluene are added in the reactor, mechanical stirring is dissolved, and 1g potassium iodide aqueous solution, 10g modified ZSM-5 are added, and...

Embodiment 3

[0045] The preparation method of solid-phase catalyst comprises the following steps:

[0046] (1) Preparation of ZSM-5: add 100g of sodium silicate, 50g of sodium metaaluminate, and 20,000mL of deionized water into the reactor, stir evenly, add 60g of tetrapropylammonium bromide, stir evenly, add sulfuric acid to adjust pH , heated to 180°C, hydrothermally crystallized for 72h, washed with water, dried, and calcined in a muffle furnace to obtain ZSM-5;

[0047] (2) Preparation of modified ZSM-5: 105mL of N,N-dimethylformamide, 10g of ZSM-5, 10g of 2-bromopropionic acid, and 1500mL of dichloromethane were added to the reactor, stirred mechanically, and reacted at room temperature for 18h, Filter under reduced pressure, wash and dry to obtain modified ZSM-5;

[0048] (3) Preparation of phosphorus-modified ZSM-5: 6.5g of triphenylphosphine and 17g of toluene were added to the reactor, mechanically stirred to dissolve, 1.4g of potassium iodide aqueous solution and 10g of modified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com